I want to build in" Duet 2D Wifi " into a Anycubic Predator.

-

@oryhara I've had the same issue as well, whether I've been using cheap PTFE or Capricorn tubing. I ended up changing the pneumatic fitting on the BMG clone and I've since had no issues

touch wood, fingers crossed.

My PTFE tubing is significantly shorter than the original at roughly 200mm. -

WHat did you change the extruder fitting to?

also what is "touch wood"

I only had one grommet clip so i switched from the e3d groovemount bowden fitting to the bigger fitting that was on the extruder that came with the predator. It's grommet maintained tension without a clip so I thought that would help.I am concerned that the 'flying extruder' mount is letting the extruder wobble around too much and that swinging is being constrained rigidly(distance-wise) only by the PTFE tubing. THe springs constrain it flexibly. so it bounces all over the place against the PTFE tubing and that just rips it out.

So 200mm only tube. That seems like it is at least as long as the original. I wonder if a direct mount would fix the problem. Or perhaps if I anchored the wire harness to the extruder to limit its motion and constrain it by one more point. again, rigid with respect to distance.

-

Touch Wood is a local statement meaning "may my good luck continue". Also sometimes called "knock wood".

-

Thinking on it, it may only be around 150mm of PTFE i've used.

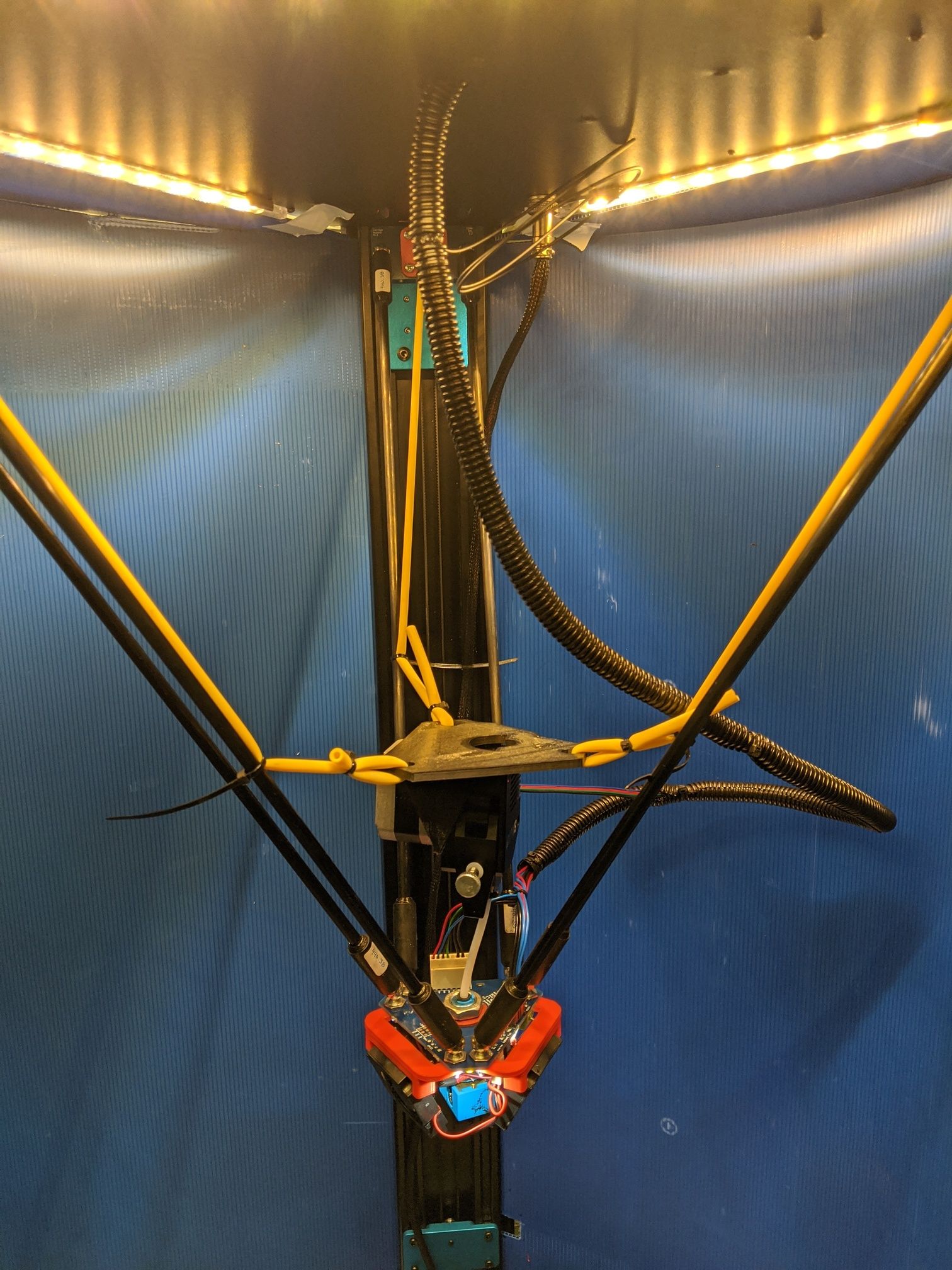

I tapped the hole in the extruder 1/4" BSP and fitted a fitting I had on hand.I've changed my flying extruder from using springs to using rubber tubing.

I've also constrained the extruder from wobbling around by cable tieing the rubber to the arms as low down as I can.

I'll upload a picture when I get home later -

@oryhara said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

My printer is stripping the ptfe out of the bowden couplings, which is why i ask. Going to clean out the hotend tonight in case that's the cause.

Do you mean that the extrusion force is pushing the PTFE tube out of the couplings? If so, that could mean that you are printing at too low a temperature, which could mean that your thermistor settings are incorrect in the M305 commands in config.g.

-

@dc42 I had mine pull out when I was using a PT100 and when using the stock e3d thermistor (with the correct config settings).

Some of the couplers used are just rubbish. -

I'm pretty sure the thermistor settings are correct. they are the settings for an e3d thermistor, which is what I'm using. They read about the same as the bed when cold(room temperature), but I don't have the means to really test them better than that.

Or i don't know means to do so. I guess I could take another printer's temp probe and hold it against the heat block but that sounds like a dumb idea. and potential to break both printers and burn my hands.Yes it strips the PTFE tube out of the coupling. Usually at the extruder end. My other bondtech extruders did this when I first switched to Volcano. Even at ludicrously high temps(300 for ABS) it just couldn't melt enough plastic to extrude at that speed. So its not just temp, it's speed. Or perhaps more accurate to say its volumetric extrusion melt rate that is the limit.

Except i'm printing at the same speed as before with the knockoff e3d head that came with the anycubic printer. And the same nozzle diameter(.4mm) but this time with a bondtech extruder.

The no-name extruder it came with would strip the filament instead of the PTFE tube, which is almost a downside to bondtech. Teeth on both sides won't strip the filament, but it will pop the bowden tube out and then feed a bunch of filament through. If the filament just gets a bite out of it, you lose the print, but the filament not fed is still good. I couldn't re-roll the filament it fed after popping the PTFE tube, and it was several meters went to waste. granted that's like $2 or something, but still kinda annoying.

I probably need to clean the nozzle. I probably had a gap at the bottom of the tube inside the heat break from the grommet moving down on insertion, then back up to apply the grommet clip. I should hold it up while inserting the tube to make sure there is no play before getting the clip on there.

Are the threaded ptfe couplings better than the groovemount-type couplings?

-

I promised an image of my setup so there you go. -

Very interesting. So it doesn't cause a problem to have the tubing anchored to the magball arms like that?

I got a good-ish print last night. Capricorn tubing at about 150mm and a wire-cable anchor between the extruder and effector seems to have done the trick. Now that the tubing isn't being pulled away from the hotend by the spring tension(as the cable is shorter than the tube) it fed fine for an 8 hour print last night.

Except I did notice some layer shifting. Around layer 4 and then up at around layer 50. Only those 2 shifted. I'm using the config.g from your github, jay, and I haven't checked the temp on the motors to see if my current might be too high. They are inside the covered top part so it's not that easy to do or I would have. The bondteck extruder motor was a bit warm when i last tried to resolve a feed issue, so its probably getting too much current.

Also: based on your picture, I think i'm running my extruder backwards. I have it feed in through the other end. Just to clarify: the tension screw should be on the end that goes "out" to the hotend?

I can't find my bondtech documentation to verify for myself. But it appears that is how yours is set up.

One final question: what fan ducts are you using there?

-

The bondtechs can be used either way. I don't think it matters.

I haven't had any issue with the tubes being anchored to the arms.

I've also been suffering from the odd layer shift on random prints. The motors are running cold and I'm currently up to 1400ma from the 1000ma I was originally using. Still not 100% sure what motors are used.These are the fan ducts

-

@oryhara said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

Also: based on your picture, I think i'm running my extruder backwards. I have it feed in through the other end. Just to clarify: the tension screw should be on the end that goes "out" to the hotend?

Bondtec can run either way.

-

@jay_s_uk said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

I haven't had any issue with the tubes being anchored to the arms.

I've also been suffering from the odd layer shift on random prints.Those two statements strike me as an odd combination... of course, I can't see what you can, I'm just reading...

-

@Danal said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

@jay_s_uk said in I want to build in" Duet 2D Wifi " into a Anycubic Predator.:

I haven't had any issue with the tubes being anchored to the arms.

I've also been suffering from the odd layer shift on random prints.Those two statements strike me as an odd combination... of course, I can't see what you can, I'm just reading...

Yea, I get why you'd say that. I think its more down to changing the material I'm printing with and I'm obviously running the motors underpowered as they don't get anywhere near remotely warm.

If the extruder isn't anchored, it wobbles like **** -

so I added a G32 to my start gcode. using the smart effector.

and It does the first layer too close to thebed. Like so close that filament can't extrude. I have to set babysteps up about .3mm to let it extrude at all.What should I be changing to fix this?

Sorry if the question is off-topic, but this thread has the details of the hardware I'm using. (anycubic predator, Duet maestro, smart effector, bondtech extruder).

-

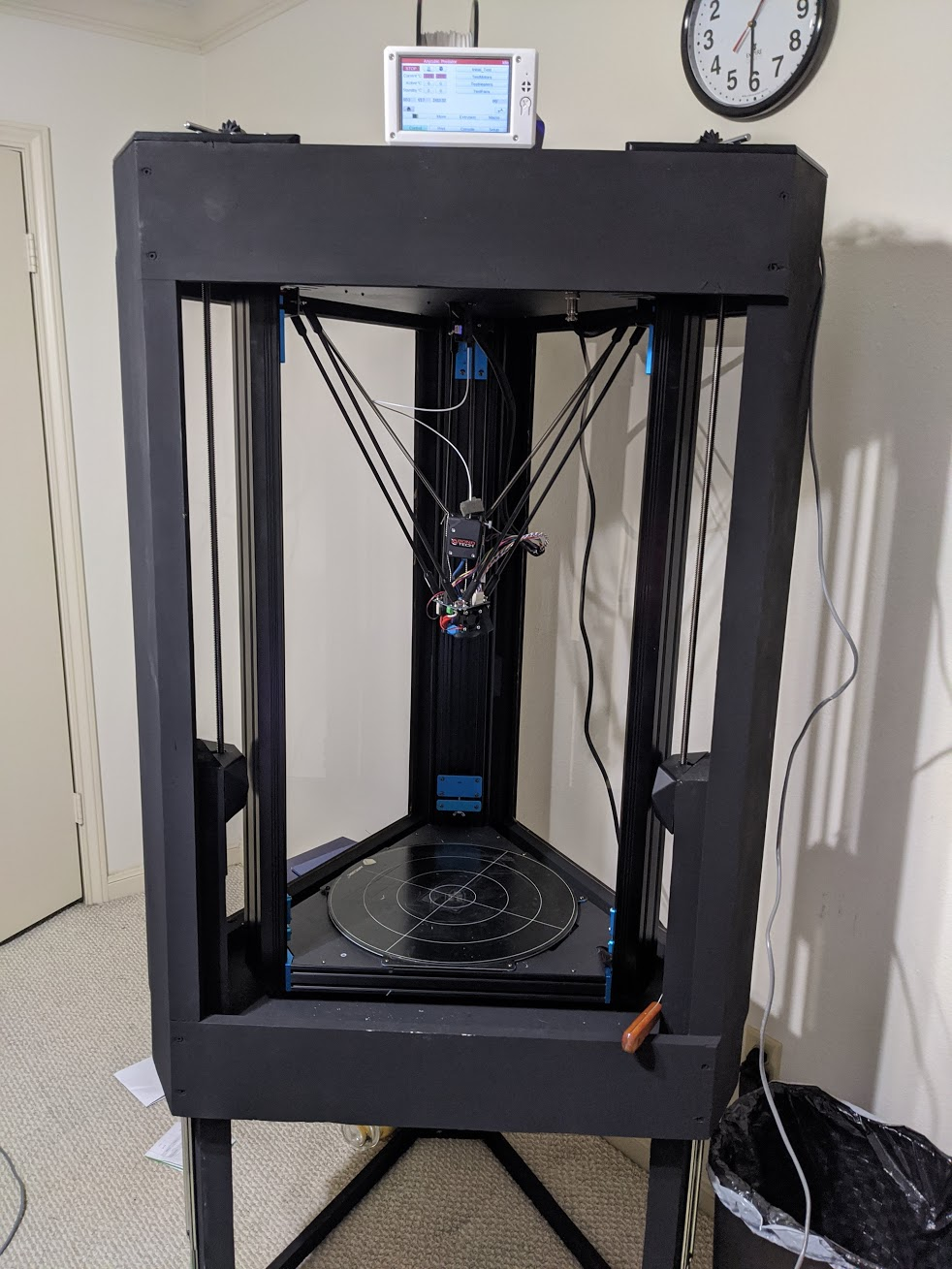

I like your enclosure, jay. I also built one for my printer, though its not quite done yet. I have to put the door on hinges and make a latch.

And seal the top. then probably add a hairdryer or something to heat the chamber.

The legs are on acme screws and up top are gears to raise-lower the printer box so I can take it to my user group.

Yes I know my clock is backwards.