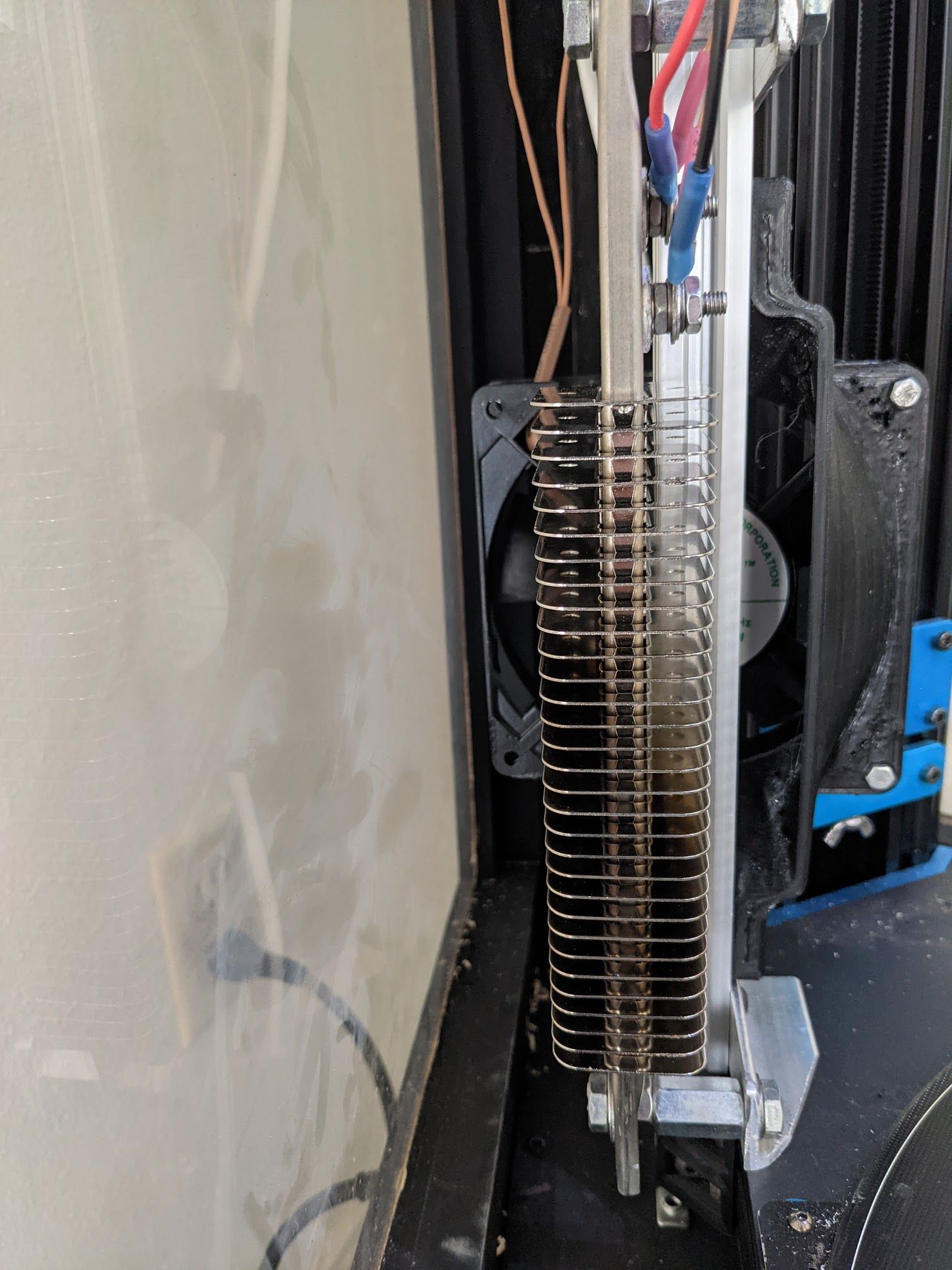

It works. Took about 23 minutes to reach 50 degrees.

I want to thank everyone here for their help.

In case anybody wants to repeat my success, here is what I did:

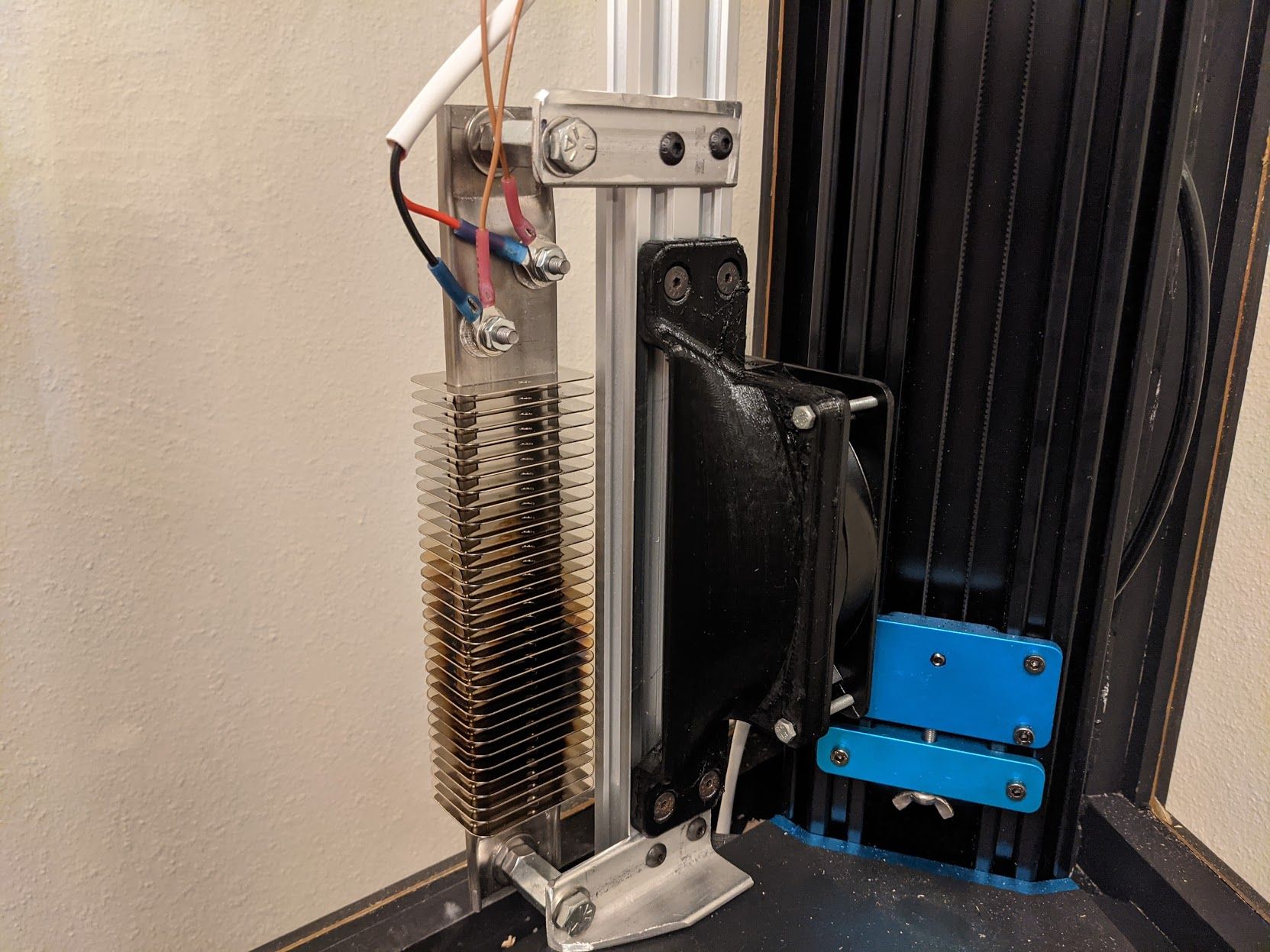

this heater element:

https://www.mcmaster.com/3575K411/

with this fan:

https://www.mcmaster.com/1976K95/

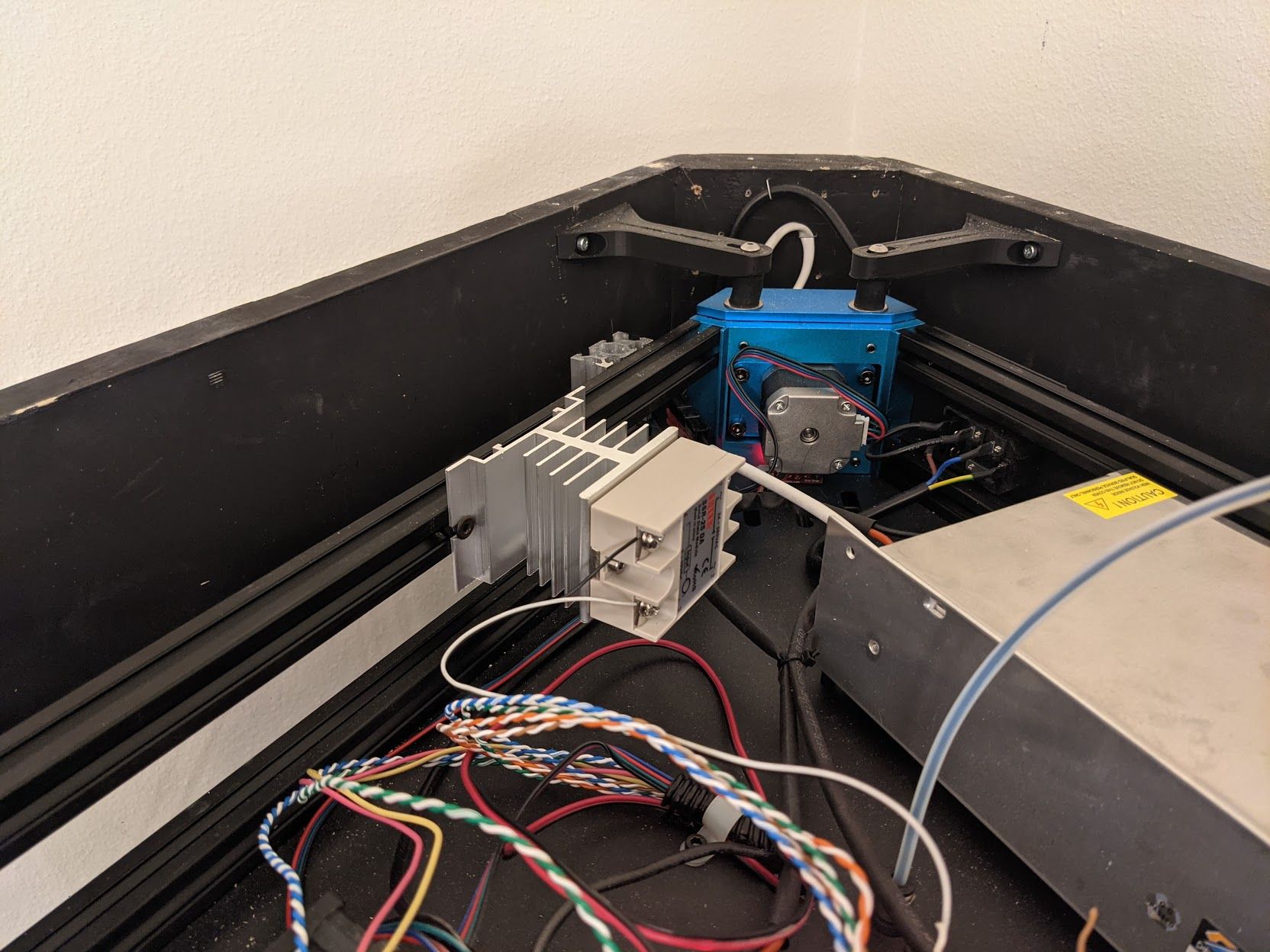

this SSR:

https://www.amazon.com/gp/product/B07FVR37QN/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

this thermistor:

https://www.amazon.com/gp/product/B07V6YBFSY/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

and this TCO:

https://www.amazon.com/gp/product/B07JM2DB67/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1

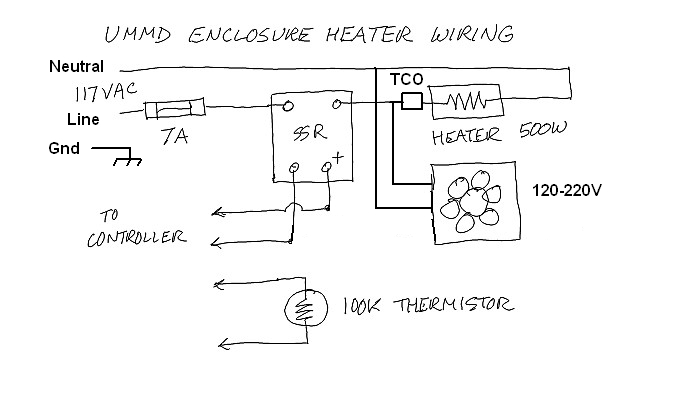

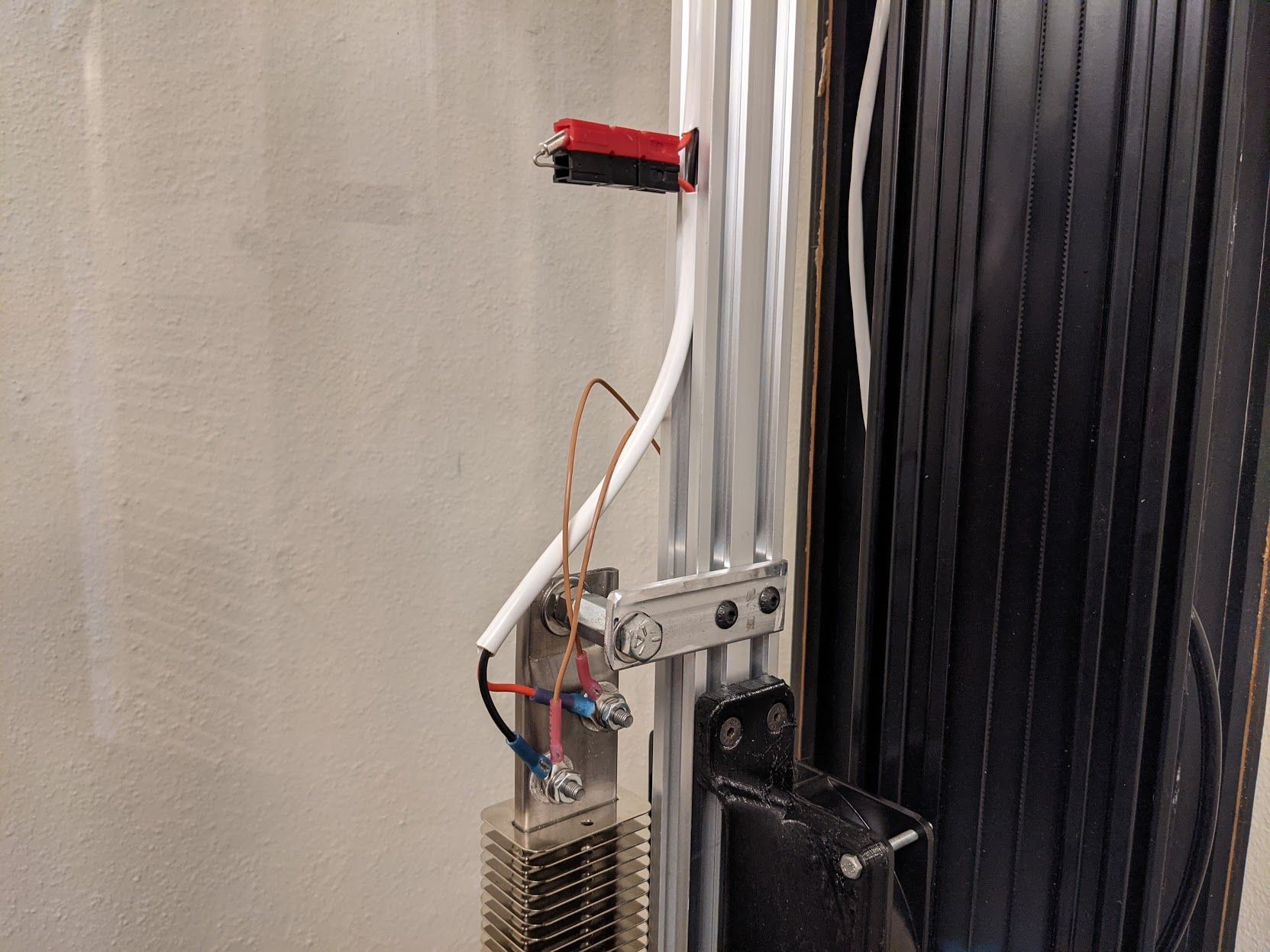

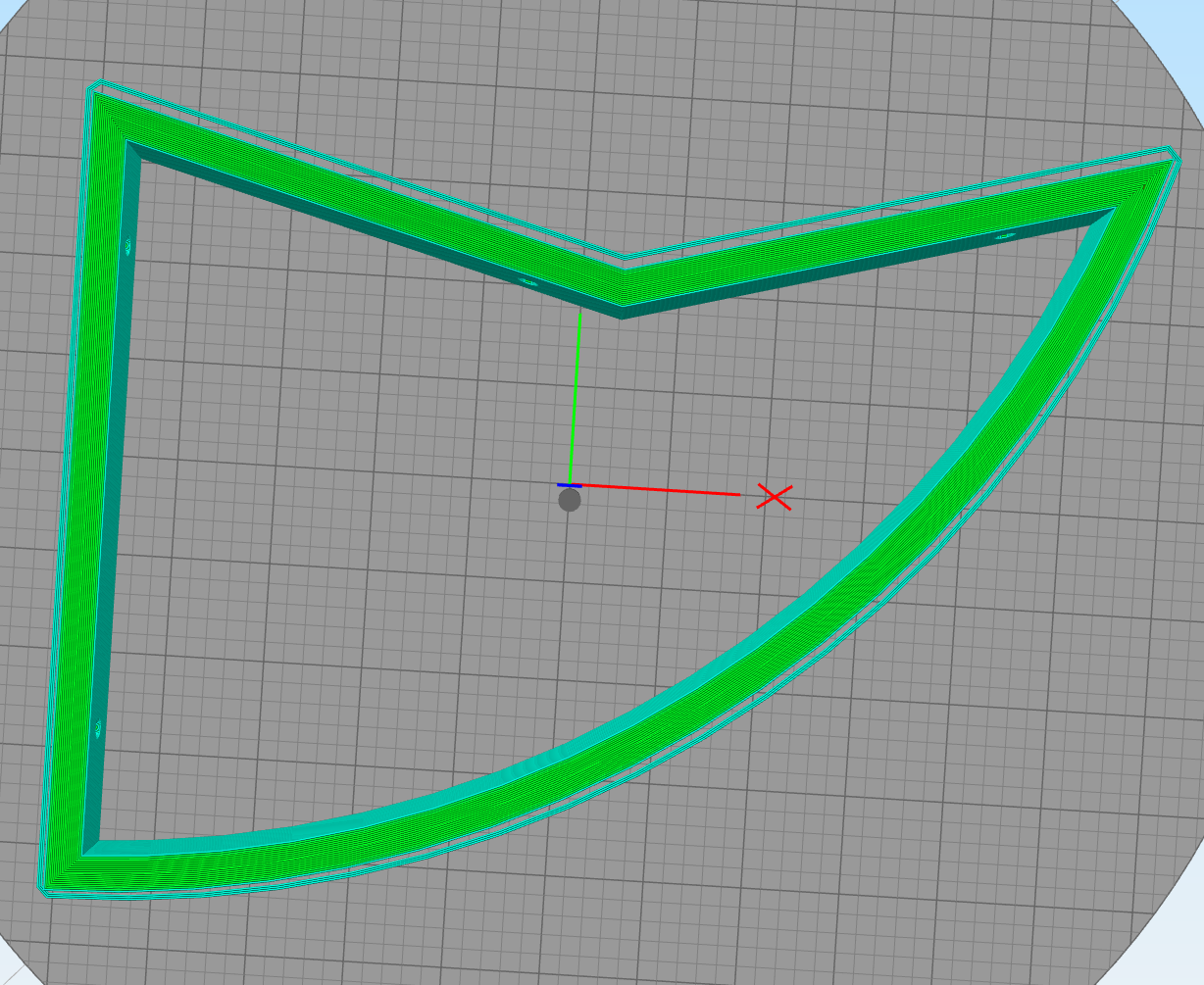

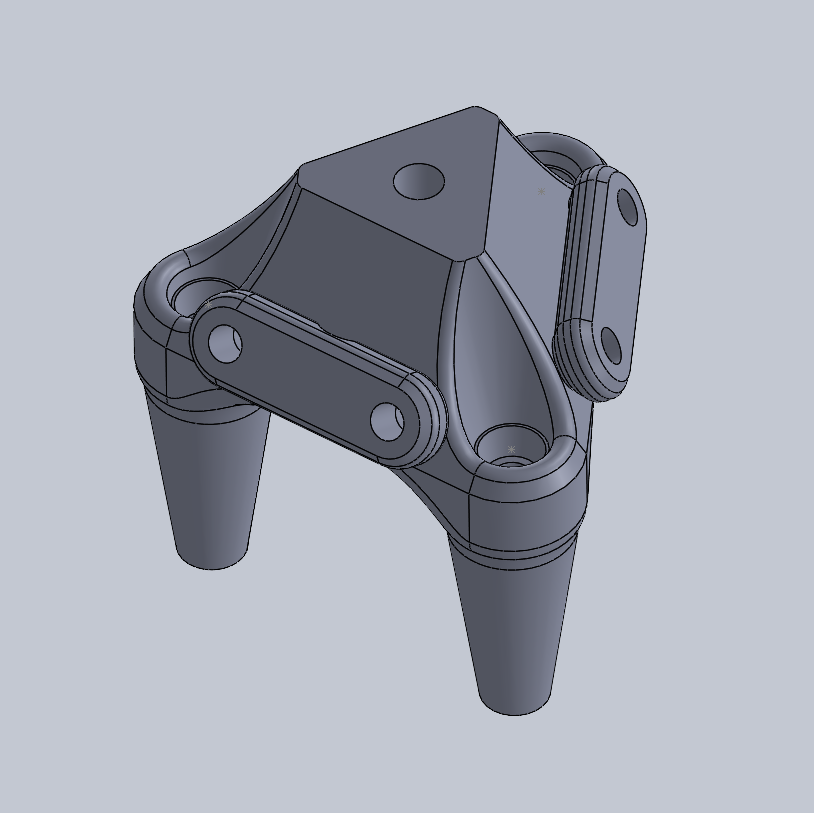

Wired them up per this diagram

@mrehorstdmd said in Chamber heater plan:

Wiring: