Erratic PT100 Readings

-

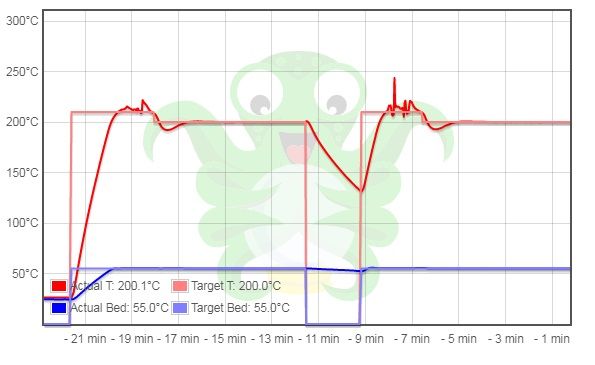

I recently upgraded a delta printer/duet wifi to use the PT100 sensor for the hotend. This allows me to swap effector/extruder assemblies with another similarly configured delta printer. I am seeing a lot of erratic temperature readings on the newly configured system which I do not see on the other printer and I see the problem with all of the effector/extruder assemblies.

This does not happen every time I print but the graph shows a back to back occurrence where I killed the print and started it over. It always seems to start after the initial heat up is completed and the problem clears by the time the temperature drops for the second layer.

The stepper and PT100 wires in the umbilicals are separately shielded. Both Duet boards are running v2.02 but the problem system is 1.0 hardware and the other is a 1.04.

I guess the next step is to swap the PT100 boards and see if the problem moves to the other system. Has anyone else seen this before?

-

I recently had some similar PT100 issues with heater faults being reported. Turned out to be a break forming where the wire was soldered. I replaced the wiring harness for it and the problem was solved.

You can also try using the alternate channel on the daughter board.

-

I totally agree with @Phaedrux , looks exactly like what I saw when a factory crimped connector on my RF100 went bad, started off slightly intermittent and I put up with it, then rapidly got to 'heater fault' levels.

I do note, as you do, how the graph flattens after the first layer. Maybe slice a model with the main temp and no fans on the first layer and see how it does. Mine was intermittent, but did occasionally pop up mid-print too. A failing thermistor might look the same too I expect.. start with the wires and if nothing seems bad, swap it out I guess.