Alternative Smart Effector Mounting

-

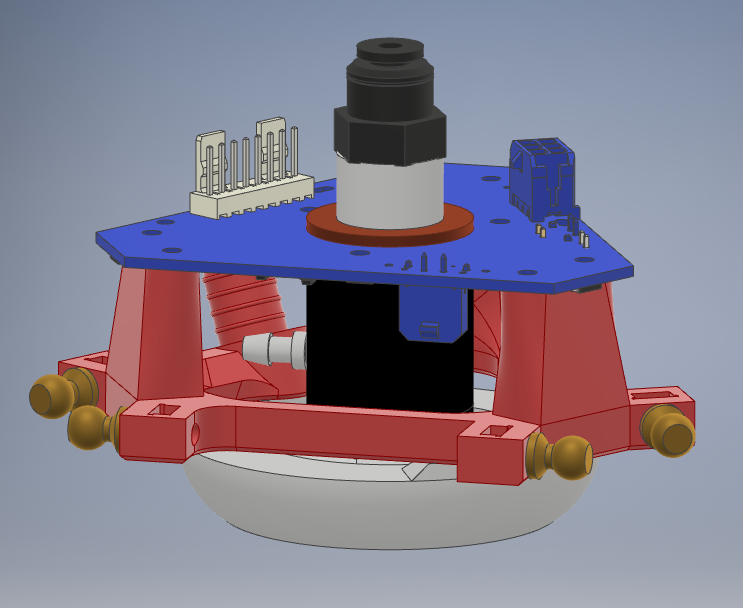

I am converting my existing existing E3D v6/smart effector combo to a water cooled version. You can see the current progress in the existing thread here.

I ordered an off-the-shelf water cooled heatsink from Germany. I plan to turn down the groovemount down to 12mm on a lathe and thread it to M12 myself. This seemed a good idea until some pointed out that there is less than a mm between the minor diameter of the external thread and major diameter of the internal thread (for the M10 bowden coupling).

Therefore, I am thinking about possible other ways to afix my heatsink to the smart effector. Assuming a smooth 12mm diameter shank where the groovemount used to be.

-

@Nxt-1

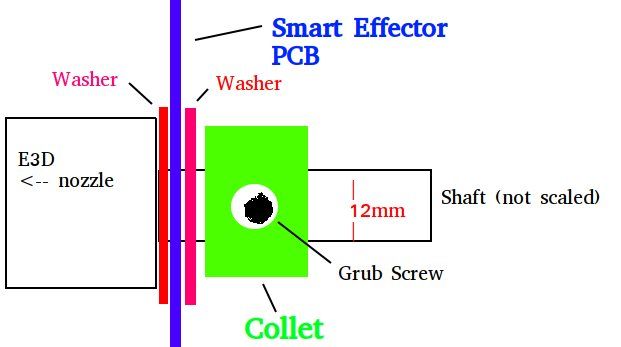

some sort of 12mm collet?

I just knocked this (pretty bad sketch up, it's oriented weirdly ;left-right, not bottom-top, sorry)

Might be hard to get enough 'squeeze' on the collet.. but a 12mm collet should not be hard to get/make.

edit; oh, and it's not E3D either.. my bad. -

@EasyTarget said in Alternative Smart Effector Mounting:

@Nxt-1

some sort of 12mm collet?

I just knocked this (pretty bad sketch up, it's oriented weirdly ;left-right, not bottom-top, sorry)

Might be hard to get enough 'squeeze' on the collet.. but a 12mm collet should not be hard to get/make.

edit; oh, and it's not E3D either.. my bad.That's actually quite a clever idea. The only downside I see, I that you lose clamping pressure that the nut would normally provide. On the other hand me pushing down on the collet while thightening the grub screw should suffice for the application at hand I would say. We are not trying to squeeze the pcb until breaking after all.

-

Another idea, my machining buddy came up with is a adapter piece that fits into the M10 hole and converts to something like an M14. This leaves room in there for the M10 bowden coupler. This has the disadvantage of making the whole contraption longer, thus wasting space.

-

After further debating it with my machining guy, we ended up turning down the heatsink top shaft to 12mm diameter and not thread it at all. To be able to clamp it, a simple 10mm high spacer was machined to sit between the redish washer at the top of the pcb and the bottom of the screw in bowden connector. This way the bowden fitting effectively does the clamping.

-

@Nxt-1 said in Alternative Smart Effector Mounting:

This way the bowden fitting effectively does the clamping.

Very simple and effective; good solution.

Could I ask where you got the waterjacket/cooler from? It's an upgrade Sunflower desperately needs(*) but I've totally failed to find a (sensible) E3D compatible cold end for this. Yours looks much better that anything I've seen before.

(*) TL;DR.

The store room I grandly call 'the workshop' never gets damp or cold, but in summer it can overheat. It's actively ventilated, but 30C+ is normal for a few months. When this happens I have to turn retraction on sunflower right down; or she starts clogging as heat creeps too far up the heatbreak. Even with a 'better' fan and thermal paste on the heatbreak it's still a major issue.

So I've been thinking of watercooling as a way to get round this, but the only systems I found were either very homebrew, or very bulky/ugly. The best solution appeared to be using silicone cooling jackets used on the exhausts of model racing boats. But I never got beyond wishful thinking. -

@EasyTarget I got the heatsink from a German store here. My existing thread on watercooling in combination with the smart effector might also be of interest to you.