Windows 10 3D printing support

-

@fcwilt afaik, prusa mk3 will show up here

also, I had my teartime printers show up here too while I was using their original electronics.

I did not ever use this, but I'm interested in how it works and if duet can support it

(mostly in order to figure out how that works)

(mostly in order to figure out how that works) -

Hi,

I think that is something in Window's future.

Frederick

-

I think it's only USB-connected printers that show up there, and printing over USB is a bad idea.

-

@fcwilt I think it is current, not future as it exist for a while now (more then I year I think) and windows comes with some 3d tools that are not that bad neither (the 3d builder is the fastest one to merge all objects in multiobject stl for e.g. out of all tools I tried) .. so I believe it is something we at least should be aware of, irrelevant if we are supporting / using it or not

@dc42 I have zero experience printing on duet so can't say much about it but printing on smoothieware trough usb with octoprint works flawlesly for many years on many of my machines, it does not work very good on marlin as the 8bit mcu can't handle the load but that's another issue all together.. so I assume duet can handle gcode stream arriving from usb...

anyhow, I'm not 100% sure it's usb only as I am almost sure that my up mini was visible on my win10 box and up mini was only accessible trough wifi, can't be sure now and can't retest as I removed original electronics from teartime printers (their old slicer was good, the new one is not that much and they use proprietary protocol so I scrapped the electronic) ... also, even for usb, if we look how other windows printers work, you can send a "whole file" (EPS, PDF, PCL...) to the printer for printer to "process" and finally print, I doubt that the only way windows printing would be to stream realtime g-code to the printer, I rather believe you either shoot the g-code to the printer and start print (standalone) or you send stl/3mf to the printer/driver and let it handle it (convert to g-code, send to printer, whatever...) .. and I kinda believe it is the latter as neither of the printers I owned that shown in the list of 3d printers on windows supported g-code

in any way, while I'm totally happy with the workflow as is today, I'm just interested how this whole windows thing work so assumed someone on the forum already did some research

so I don't have to

so I don't have to

-

@smece How does windows 10 handle the smoothie setup over usb? Does the printer get listed automatically, or is it meant to be installed manually?

-

@bot said in Windows 10 3D printing support:

@smece How does windows 10 handle the smoothie

you missunderstood me, I converted TT printers to smoothie so they are no longer visible on win10. they were visible on windows 10 before conversion, with original electronic and original software (slicer, driver ...), and I never actually tried printing from any of the windows tools (at the time was not something that interested me) so I have no clue how it works... recently I read that prusa's printers are visible on win10 so I assumed someone knows more about it (as afaik those prusa drivers are open source) and hoped maybe duet3d is on the same path... again, more 'cause I'm curious than anything else

and now I have no printers that do support that so ..

and now I have no printers that do support that so .. -

These are my personal thoughts and gripes:

The windows 10 3D printing apps are yet another half cocked unfinished example from the Microsoft 'software experts'.

These days Microsoft tend to start a project but never finish it and then later abandon it.

As far as I remember 3D Builder came with the first distribution of Windows 10 and has exactly the same features now as it did then. The help files tell you very little and there is no guide anywhere of how to connect printers. I don't know of anyone who uses it and Microsoft gives me no incentive to start using it. -

@chas2706 said in Windows 10 3D printing support:

These days Microsoft tend to start a project but never finish it and then later abandon it.

not these days really, it was like that since DOS 2.0, but I tend to not take that as a bad thing, doing stuff on many fronts is imo a valid strategy.. the only difference is they are now sharing their rnd compared to many others (and compared to m$ in the past, that's why you say they "these days tend to.." .. these days they tend to share most of the rnd while earlier they didn't)

As far as I remember 3D Builder came with the first distribution of Windows 10 and has exactly the same features now as it did then.

Yes, but for e.g. you have a multipart (multi-shell) STL that slicers slice wrongly 'cause of that and you need to merge them .. netfabb professional does it but cost arm and a leg (and mine for e.g. does not work any more as the dongle I have require licence file too and since my previous computer died I don't have it any more and noone from previous netfabb contacts are answering emails anyu more so that's 1000eur down the drain) ... 3D builder, open, edit, select all, merge, export and it's done, super fast and flawless

... I have not used it to do some modeling / editing but this is useful enough

... I have not used it to do some modeling / editing but this is useful enough

I don't know of anyone who uses it and Microsoft gives me no incentive to start using it.

With exception of maybe Prusa printer the only one that support this out of the box are the commercial printers with proprietary electronics so no wonder why "noone uses it" .. but if more printers support it maybe more ppl would be using it and we might find it's actually useful

(or we'd figure out it's a total scam) .. but for e.g. inside SolidWorks there's a "3d print" option that works only on windows 10 ... I would, for e.g. love to know how that works .. is SW just sending the stl equivalent to the "driver" that's going to be slicing it or there's something else going on there.. aren't you curious how is that support to work? I know I am! I'm 80% sure it's going to be useles but still, I wanna know, not guess

(or we'd figure out it's a total scam) .. but for e.g. inside SolidWorks there's a "3d print" option that works only on windows 10 ... I would, for e.g. love to know how that works .. is SW just sending the stl equivalent to the "driver" that's going to be slicing it or there's something else going on there.. aren't you curious how is that support to work? I know I am! I'm 80% sure it's going to be useles but still, I wanna know, not guess

-

Just my two cents:

-

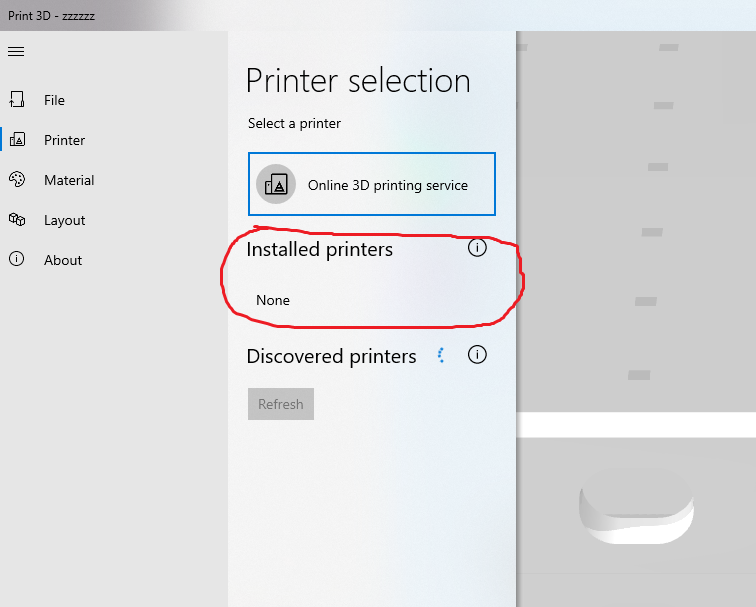

Win 10 support is indeed for USB attached printers.

-

USB attach does work, and we've all used it.

-

USB attach has its pros and cons (widely known, so I will skip them here)

And, most importantly:

- Using USB with a duet is bypassing a huge portion of its value

Duet is designed from the ground up for web-based "upload then print". Trying to use Win USB, or Octo, or whatever, is a huge step backwards for Duet. Don't let your past rob you of value with this wonderful controller. Use it the way it was designed.

-

-

@smece said in Windows 10 3D printing support:

I'm just interested how this whole windows thing work so assumed someone on the forum already did some research

think you'll find the majority* of the 3d printing community will ignore the closed source efforts, be it from microsoft or others.

*) or at least the majority of those who would improve and develop 3d printing.

-

@bearer said in Windows 10 3D printing support:

will ignore the closed source efforts,

yes, that's why I replaced electronics on my TT printers but it's good to know, also I don't see simplify3d losing sales and slowing down (even while they are not pushing new releases and are basically at same place they were 3-4 years ago while free slicers moved ahead big time) ... also, looks like we are all guessing too much, do we know it is closed source? anyone did any research? I started here on the forum, learned ziltch

so I'll move forward till I satisfy my curriosity .. it's maybe classic M$ crap but maybe... who knows .. as I said prusa is supporting them, I doubt they paid some money to them so most probably they just read the proper documentation and got informed

so I'll move forward till I satisfy my curriosity .. it's maybe classic M$ crap but maybe... who knows .. as I said prusa is supporting them, I doubt they paid some money to them so most probably they just read the proper documentation and got informed  ...

... -

@Danal said in Windows 10 3D printing support:

Duet is designed from the ground up for web-based "upload then print".

I could not care about web a tiny bit .. it is easier to do intial config with nice interface and nice screen and similar stuff but I'm old enough to remember programming machines with switches so while "easier" setup is welcome it's not a crucial part of the process as is done once per machine... on the other hand using the machine I want to send my g-code to gcodestat and I want gcodestat to upload that code "wherever" and start the print ... the reason for octoprint on my machines is

- to be able to shoot the gcode there trough gcodestat or directly from slicer

- to have automation (inform me trough telegram that it failed or finished, monitor the print with thespagethi plugin and inform me trough telegram about potential issue and allow me to cancel print remotely, upload the timelapse to a server, track usage, electricity, filament... etc etc etc.. )

as for shooting gcode to duet gcodestat does not support it, if there is api to upload g-code from network I'm sure they will add the feature if asked, but I looked trough some duet documentation and I did not find any api for that (was meaning to create topic about that)

and with regards to automation, I see it is totally impossible now with duet but I see that new version will have possibility to write plugins so we'll see

looking at the web while printer is working is not something I care to do.. I don't remember last time I looked at octoprint web interface and it works 24/7 on numerous printers here so no, the web interface of duet, while useful, is far from universal solution and is 100000% irrelevant to the question of how windows 10 printer support works...

what I hope/assume is how I'd made it myself (of course I didn't nor anyone give a .. ) is that there's open interface / api trough which one can on one side

- request hw info about printer / capabilities

- request current state about printer (position, temperatures...)

- can send mesh to be printed

and on other side - register "driver"

where a "driver" behaves like your 2d printer driver, you can just click print and it will slice and print with default options or it will open a "slicer" where you decide on details and then let it print...

now how the "print" actually works don't have to be any different than any of the curent methods, some printers will have to be on the usb and receive g-code stream, some will be on usb but will receive a g-code file (or a proprietary format file in case of closed source printers) or the g-code or proprietary file will be sent trough network or ..

so what I'd do is just a open api that allow apps to interact between themselves and the user, there's zero reason to limit that to streaming g-code trough usb

now, yes, we are talking about M$, maybe it is only streaming g-code trough usb but I try to keep my mind open for that to actually be something useful

-

May I respectfully correct some assumptions in your post above?

- it is easier to do intial config with nice interface

Actually, initial config is not available through the web interface. Initial config is a seperate tool that builds a configuration file as a "starter", then a bit of adjustment is expected to fine tune.

The web interface is designed to operate the printer. Not configure it.

- and with regards to automation, I see it is totally impossible

Many people have written to the API (see next post) and automated lots of things.

- looking at the web while printer is working is not something I care to do

I assume you look at something? A front panel? Something? When you need to interact with the printer?

Duet based printers don't have front panels (unless you add one). The web interface is the only way to interact with the printer (again, unless you add something).- numerous printers here

One of the many things created by 3rd parties for Duet is a "one pane of glass" monitor for print farm operators.

-

API exists. Documented here: https://github.com/chrishamm/DuetWebControl/tree/legacy

MANY people, including me, have written monitors, alternate interfaces, etc. Including "one pane of glass" monitoring of print farms. There are plugins to direct upload to Duet from numerous slicers, and writing a new one mostly involves understanding the slicer.

Automation of a Duet is very possible. As mentioned above, numerous people have done it. Same API. Many, if not all, of your bullet points are available. EXCEPT, the windows "Driver". Perhaps, given your interest level, and the well documented interface to the Duet, you'd be interested in creating that?

-

found the api for upload

here the /rr_upload works great ..

here the /rr_upload works great ..gcodestat is super simple little app that calculates the time to print but I fear bit more than upload to duet is required there as it currently calculates times based on smoothieware code (acceleration and junction deviation instead acceleration and jerk) so to have it calculate properly time for duet it would require bit more stuff there... anyhow even as is it gives way more accurate timing info than simplify3d/cura/slic3r do

i understand that with api it's possible to use external apps to talk to the duet but that just proves my point that "web interface" is far from "the one and only interface"

...

...as for the windows support, as I said, I'm just, for now, curious how the darn thing works / how it m$ intended to be used and if there's anything usable in that work they did... so since I started migrating to duet (one of the printers is now having duet board, not yet operational but soon) and duet is most advanced electronics I have (klipper is in the run, smothieware old is far behind, smoothieware new is "in dev stage" for ages now so I gave up on it, replicape/revolve I have in drawer but have not tested yet ... so I'd say attm duet is def the most advanced one I have setup in a printer) ... not a big deal, I'll just look further till I satisfy my curiosity and if I find that it is useful for me I will, of course, write some code for it

-

@smece said in Windows 10 3D printing support:

i understand that with api it's possible to use external apps to talk to the duet but that just proves my point that "web interface" is far from "the one and only interface"

Um... the API is HTTP requests. Literally a "web" interface.

And I believe my point was about "upload then print" vs. "USB Streaming". I'm not really sure how we got into such a serious disconnect over "web".

So let's set "the web interface" aside. It's really about USB. And, a look at MSDN documentation makes it very clear that Win 10 3D printer support is USB only.

-

@Danal said in Windows 10 3D printing support:

May I respectfully correct some assumptions in your post above?

Ah, we use and look at things very very very different, so just for clarification, nothing else:

- it is easier to do intial config with nice interface

Actually, initial config is not available through the web interface.

You obviously look at "inital config" as making the set of files in sys directory, I on the other hand look at "initial config" as bringing printer to the state I do not care to look at it any more

I assume you look at something? A front panel? Something? When you need to interact with the printer?

I don't look at it, most of my printers don't have a panel, and while nice, I'd probbly remove the panel from this ender5 I put duet in.

my interaction with a printer is telegram notification print is done so I go take the print out of the printer, or telegram notification from TSD that some #%$^# happened and I need to remove the garbage from the printer and figure out what happened + restart print... the "monitoring" of the "printer" is not something I do after the initial config is done.. do you look at your laser printer lcd / web interface while printing or you just go by retrieve printouts and interact only when you get email that toner is out?

-

@Danal said in Windows 10 3D printing support:

And, a look at MSDN documentation makes it very clear that Win 10 3D printer support is USB only.

I didn't find msdn doc about 3d print support, that's what I'm looking for, please link me

-

https://docs.microsoft.com/en-us/windows-hardware/drivers/3dprint/

That just a landing page, see left nav.

-

@smece said in Windows 10 3D printing support:

You obviously look at "inital config" as making the set of files in sys directory, I on the other hand look at "initial config" as bringing printer to the state I do not care to look at it any more

Actually I believe we are saying the same thing. I very rarely look at the panel (or web) of a printer when it is "just printing". Maybe occasionally to see an estimated end time. That's about it.

my interaction with a printer is telegram notification print is done so I go take the print out of the printer, or telegram notification from TSD that some #%$^# happened and I need to remove the garbage from the printer

How do you load a different filament? Do you ever have to jog the carriage to remove that garbage? Or heat (or cool) a hot end to replace a nozzle? Or wish to home and move around some after replacing a broken belt?