Need your advice, V-Slot VS Linear Rail.

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

I've seen folks do that but I wouldn't.

Frederick

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

That would depend on the length of the guide and the mass it has to carry or any other forces that might be applied, e.g. belt tension. I guess you might get away with it if the length was short and the mass was low but otherwise it is likely to deflect. Which brings me back to something I said earlier which is, if you have a frame member made from V slot such as Open Builds type and you want it to be a linear guide, do you add gantry plates and Delrin wheels, or do you bolt on another complete linear guide? I personally don't think there is a right or wrong way to do it and the choice largely comes down to other factors like cost, personal preference, what fits best in the space available, noise, etc etc.

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

(considering to upgrade my HEVO but thinking of the moving mass in Y direction).

The RailCore designers have chosen to do exactly that, but that is also the reason the railcore design is limited to 300mm. Personally Iwould rather see an extrusion used.

-

linear rails are not meant to stand on its own. It might work if you take bigger ones (like mgn15).

but the recommendation is to mount them on something sturdy. -

@DeltaCon said in Need your advice, V-Slot VS Linear Rail.:

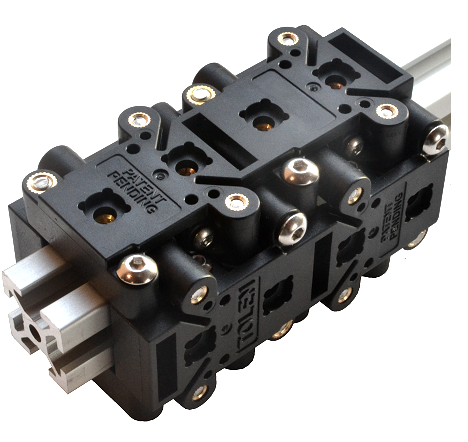

However I would like to bring these into the equation:

Look at the specs. they look very promising and are much cheaper!

https://us.misumi-ec.com/vona2/detail/110302192160/?HissuCode=PLRH25-560Seen a huge laser engraver made with these and is crazy fast and precise .. no clue how much load they can take (on the negraver they only house a mirror) but without load they are precise ... pretty loud one might say but..

Or how do we feel about these:

Specifics at: https://www.exoslide.com/

For 20x20, 20x40 and 40x40 available. But maybe not the cheapest solution.I experimented with very similar solution some years ago, the problem I had is that aluminium deformed over time ... maybe it was too tight, dunno, but I gave up using it for 3d printers, I still use this type of linear guide for my touch screen human finger simulators

(they carry only few grams and precision is not important, 1mm error is acceptable)

(they carry only few grams and precision is not important, 1mm error is acceptable) -

@deckingman said in Need your advice, V-Slot VS Linear Rail.:

@DeltaCon .........and there is also Igus Drylin which is a route I might consider if ever I build another machine

I allowed my selfe to believe drylin hype so I build a whole machine with drylin, both linear rails and rods+linear bearings... alu rails, alu rods, beautiful black alu, pre tensioned bearings..

precision ... wow, it is precise, they do wear over time, but after ~2 years of printing (average 5h per day) I can see no ware on any of the drylin parts and from what I discussed with guy's that sold me all those parts, with the forces my machine is exerting they will last forever. and sound, they produce none... but

- price, all parts for a relatively small (25x25x25cm) printer cost me a lot of money, like 3x more than original hiwin + local representative have huge margin and shipping + customs + fees is huge here so that's additionally a problem both for price and for availability... should not be a problem for everyone but for me that was huge issue

- alignment, there really is no play here, aligning 2 12mm rods with high-quality linear bearings is kinda walk in a park, I can do it in no time with zero stress... hiwin original takes a bit of time but is not a big deal, you align them nicely... drylin rods, hours, hours, hours, stress, stress, I hated myself, the printer, everything .. and rails, drylin reails, took me days to properly align them .. just the final half-turn of the screw is enough to move it out of alignment and for them to start binding... now, you can, they say, leave them like that, binding, and they will "seat" themselves (grind the plastic) but I didn't want that so .. it can be a problem

- even with perfect alignment the required force to move is many times greater that hiwin

now, super pro, one that I didn't expect at all!!! ringing was gone!!! all ringing - puf, gone ..

so, next printer, dunno, drylin is always in my mind, just the price is tad problematic, and I have zero idea how they behave inside a 70-90C chamber

One thing that hasn't yet been mentioned is noise. Vslot (and Drylin) are practically silent.

original hiwin is silent, I have huge cnc machines with hiwin rails that you can't hear till the spindle is on .. they are 2-3 orders of magnitude more silent than 8mm rod and linear bearings you can find on prusa i3 or wanhao i3 ..

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis or does it need to be attached to an aluminum extrusion for extra strength?

depends, the 12mm I would not dare, 16mm maybe some shorter distance like 25-30cm, the 25mm one can but 25mm one is iirc 1kg for 50cm (can't measure now, but can tomorrow if you want the info)

-

@zapta said in Need your advice, V-Slot VS Linear Rail.:

Can a linear rail stand on its own as a X axis

IMHO, no. That would be unwise.

-

Thank you for your participation on this subject ...

I now see advantages and disadvantages in both systems.

@deckingman said in Need your advice, V-Slot VS Linear Rail.:

@ Rudy2A Un conseil si vous décidez de choisir la route Vslot est de ne pas utiliser une seule plaque de portique, comme indiqué sur votre première image, car les boulons pourraient potentiellement "fléchir". Utilisez des plaques doubles pour que les boulons soient fixés aux deux extrémités plutôt que la disposition en porte-à-faux si souvent utilisée. Ce genre de chose

I think I'm moving towards the Deckingman system.

but I also think that I could create my own model inspired by that

@DeltaCon said in Need your advice, V-Slot VS Linear Rail.:Ou que pensons-nous de ces

points :

Détails sur: https://www.exoslide.com/ Pour les formats 20x20, 20x40 et 40x40 disponibles. Mais peut-être pas la solution la moins chère.Thank you, anyway, I am interested in any other information.

-

The cross sectional area of the guide rail, the acceleration you use, and the mass of the extruder carriage determine whether you need to use something to reinforce the guide rail.

I use a 24 x 8 mm linear guide for the X axis without anything to stiffen it and it works fine. I don't think I'd use a 9mm guide rail that way, though.

Keep in mind that if the machine 's frame is aluminum and you use linear guides for a mechanism with the bed moving in Z, temperature increases will move the Y axis linear guides apart. If the X axis guide is bolted solidly to the Y axis bearing blocks, the mechanism may bind, especially if you heat the enclosure to print ABS. You can avoid that problem by using two bearing blocks on the X axis linear guide- one for the extruder carriage and one to bolt to one of the Y axis bearing blocks. That will allow the Y axis rails to move apart because the X axis rail will be able to slide in the second bearing block.

-

@smece said in Need your advice, V-Slot VS Linear Rail.:

original hiwin is silent, I have huge cnc machines with hiwin rails that you can't hear till the spindle is on .. they are 2-3 orders of magnitude more silent than 8mm rod and linear bearings you can find on prusa i3 or wanhao i3 ..

Huge CNC machines tend to move and accelerate a lot less fast, that may contribute to that.

-

@DeltaCon said in Need your advice, V-Slot VS Linear Rail.:

Huge CNC machines tend to move and accelerate a lot less fast, that may contribute to that.

only during the cut, not during the move, since they are normally much larger the G0 need to be fast .. mine are not some super fast machines (G0 moves at 300mm/sec or F18000, limit is F20000) but I worked on beasts that are much faster.. original hiwin is very quiet .. for e.g. on one of my machines I had X on the 4 25mm rods and linear bearings (original SKF, preloaded, yadayada..) when I converted that to hiwin rail, it's night & day

... now, for e.g. I had a carriege failure after some tens of thousands of operating hours and I purchased locally a new carriage, it was sold as original but was a PRC copy, fitt was nice and behaved like original but was loud .. no matter how much grease we pumped in the noise was ... uh .. so I brought one from germany a month later, noise stopped immediately

... now, for e.g. I had a carriege failure after some tens of thousands of operating hours and I purchased locally a new carriage, it was sold as original but was a PRC copy, fitt was nice and behaved like original but was loud .. no matter how much grease we pumped in the noise was ... uh .. so I brought one from germany a month later, noise stopped immediately  ..

..I know some ppl locally that go purchase PRC linear rails, take all the balls out and into trash (actually they give the balls to local knife makers but irrelevant) and purchase new balls from sweden/germany and say they get precission and smoothness and silence of original rails at half the cost of original ones .. I never tried so can't confirm, sounds interesting for sure