P3Steel / Prusa Y-Axis End Plate Bracing

-

Morning,

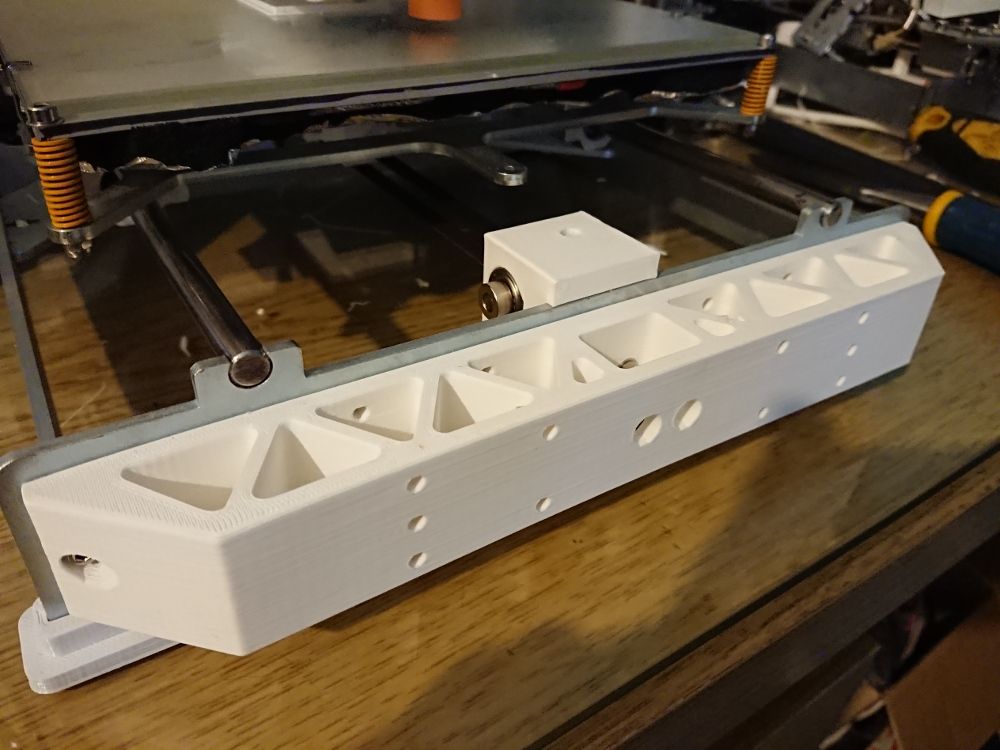

Working on a PLA brace for the end plates that support the y axis smooth rods, motor, and idle pulley. Any one tried this? Any spoilers on the improvements you saw? Bracing a steel structure with PLA may seem odd, but the steel is 3mm plate under bending in its thin section and the PLA brace is chunky! About 30x30x240mm, and a real exercise to fit on the plate.

-

Here we are! Some on the rear of the machine. PLA being used to stiffen a mild steel structure!

On reflection it is a crappy design that relies on the press fit of the smooth rods to maintain the rigidity of the two plates.

-

It's made a definate difference. The predominant ring at 31hz has all but gone leaving a second at about 20hz, but critically this isn't as severe and even on both axis.

As per usual the attention is diverted onto another issue, and in my case it is back to the part cooling duct design.

-

@DocTrucker Nice! I suppose the way to fix this is in the original is to have a full width horizontal metal beam on the inside, that T's into the end and side plates.

Ian

-

To be honest it's not 100% original thought by me. I noticed belt tension was bowing the end plates in then noticed much more vibration in the middle of the plate relative to the desk when compared to the edges. Then thought about adding a stiffener, and remembered a picture of another p3steel or prusa with some weird bits bolted on the front plates.

-

Our hackerspace designed the LOGresse, a 3D printer derived from the P3 Steel. It has many improvements, one of them is the add of reinforcement plates in the corners. I think you could make ones with 3D printed parts.

-

I'd like to have a crack at a P3Steel style CoreXY eventually. Learned a lot by forcing myself to resist the easy gain of v0.6 to Ethernet or v3 controller until I was confident I had reached the limits of the v0.6.

I think I am now getting close, with some moray (sp?) like patterns across the bow of the benchy (39min build, 0.25mm layer, 0.4mm nozzle, 10% infill, 3 layers top/bottom/vertical) that I feel are linked to the 16 microstepping of the v0.6 and the 1.8 degree steppers. But as I've already mentioned I need to revisit my part cooling fan duct again. That has been a big step back recently, but counteracted by the move to direct extrusion. Leaving a rough net gain, but crap low angle performance.

-

@DocTrucker said in P3Steel / Prusa Y-Axis End Plate Bracing:

with some moray (sp?) like patterns

Moire, or Moiré for the pedantic!

If only you could bring yourself to buy a Duet 2 (Wifi, ethernet or Maestro), you could benefit from the 256x interpolation at 16x microstepping! I still use 1.8º motors on something similar to a P3Steel, and get no Moiré patterns on the bows of my Benchys. They really are amazingly smooth for a cobbled-together printer that uses an X axis I printed 8 years ago, and 3mm filament! Though perhaps I should try a test with interpolation turned off.

Ian