Best posts made by fma

-

RE: A bit confused about fans in the WebUIposted in Tuning and tweaking

What about just putting an index in front of the fan currently used as tool fan?

-

RE: 5-axis 3D printingposted in 3D Printing General Chat

I uploaded a short video showing this print:

-

RE: Amazing use of Duet electronics by E3Dposted in General Discussion

An alternative would be to continuously extrude a tiny amount of filament on parked heads…

-

RE: Dual hotend, one motor possible?posted in Duet Hardware and wiring

We (at LOG hackerspace) designed such dual extruder using one motor. It is not driven by a Duet, but it should work.

Here is our design: https://wiki.logre.eu/index.php/DondoLOG based on this one: https://www.thingiverse.com/thing:673816 (we changed a lot of things, leading to a much more simple geometry).

Onshape designs are here: Mine¹: https://cad.onshape.com/documents/ab5e4a91e08de464a68c8fa9/w/d1a6bf327030002f2355aebe/e/4fc76c1855ace35a39166ba3 (using aluminium plates) and a derivated, made by a friend: https://cad.onshape.com/documents/44cc3aa0e2de59f4440a6e4b/w/58c86854d8b2aa8e76983bb9/e/82ef35419fb25e023c2c8b7d (using PMMA 6mm).

Feel free to ask if you want more details. Note that the second design is now working (see https://piwigo.logre.eu/picture.php?/1139, https://piwigo.logre.eu/picture.php?/1239 and https://piwigo.logre.eu/picture.php?/1286); I never tested mine...

¹ my design means to me, as it is my very first usage of Onshape (and first time I ever used a parametric CAD software).

-

RE: RepRapFirmware 3.0RC1 releasedposted in Beta Firmware

David, could it be possible to change the revision numbering and the way releases are managed?

I suggested in another thread to use a.b.c: 'a' for major release (3, here), 'b' for minor release (0, here), and 'c' for bug fixes.

Currently, installing a new release for bugs fix introduces new features, so potentially new bugs: this is not a good thing. One should be able to dissociate bugs fix and new features...

So, after the current release, which should be named 3.0.0, the next one should be named 3.1.0 (not 3.01). And bugs fix should go into 3.0.x (then in 3.1.x...)

Thanks.

-

RE: Cancel individual part(s)posted in Firmware wishlist

Here is a very simple Python script to implement Ian's idea:

#!/usr/bin/env python # -*- coding: utf-8 -*- import sys for line in sys.stdin: # Replace tool changing commands by part changing tags if line.startswith('T'): num = int(line[1:]) print "; part %d\n; process %d" % (num, num) else: args = line.split() # Only keep tool 0 temperature commands if line.startswith('M104') or line.startswith('M109'): args = line.split() num = int(args[2][1:]) if num == 0: print line, # Default commands else: print line,It replaces tool changing commands:

Tnby:

; part n ; process nIt also remove all temperature commands of tools >= 1.

To use it:

$ ./tool_parser.py <input.gcode >output.gcodePS: I only checked Slic3r output; Cura output may need additional stuff.

-

RE: New M-code to send a network requestposted in Firmware wishlist

M260 can send data over I²C bus:

https://duet3d.dozuki.com/Wiki/Gcode#Section_M260_i2c_Send_and_or_request_Data

On the I²C slave, just mimic some registers you will write from Duet to take the actions you need.

I recently developped a project using an ATtiny841 as I²C slave (this chip as a hardware I²C slave implementation), working this way. See:

https://framagit.org/fma38/Servo_Node

This is for an hexapod (I will use 6 of them, to control the 4 servos of each leg). But I will certainly use this chip for other projects, like here.

Code in Arduino/ dir is a master example; the real master will be a RPi, running my framework Py4bot: https://framagit.org/fma38/Py4bot

-

RE: Tool Free Macro not Workingposted in Tuning and tweaking

I'm also working on such filament mux, with multiple tools using the same heater, and I didn't have this problem. Could you share your tfree macro, and tell us what commands are skipped?

-

Thermostatic fan for driversposted in General Discussion

Hi!

I plan to use 2 fans to cool down the drivers, as my Duetwifi/x5 will be in a box.

Is it possible to create a thermostatic fan, routed to a specific thermistor, without any heater? If not, how should I create a dummy heater for that?

Thanks,

Latest posts made by fma

-

RE: Blender CAMposted in CNC

@droftarts Thanks. I'll ask my cousin to check.

In the meantime, he tested the ISO prostprocessor, which seems to work fine. -

RE: Blender CAMposted in CNC

Mmm, Blender CAM generates strange G-Code:

G0X0Y0Z10 X3.477Y3.144 G1Z0F500 G0Z10 X3.666Y3.004 G1Z0 G0Z10 X3.868Y2.883 G1Z0 G0Z10 X4.081Y2.782 G1Z0 G0Z10 X4.303Y2.703 G1Z0 G0Z10 X4.531Y2.646 G1Z0 G0Z10 X4.764Y2.611 G1Z0 G0Z10 X4.999Y2.599 G1Z0 G0Z10 X5.235Y2.611For lines only containing X/Y coords, G-Code simulators use the previous command (G0, here), but RRF does not seem to understand such lines... Do you confirm?

-

Blender CAMposted in CNC

Hi!

My cousin bough a used CNC which is running with a Duet2 board.

As he knows Blender very well, he would like to use Blender CAM, which does not output GCode for RRF. Which machine should he use, from this list:

- Iso

- Mach3

- LinuxCNC

- Fadal

- Heidenhain (530, TNC151)

- Sieg KX1

- Hafco HM-50

- Centroid M40

- Anilam Crusader M

- Gravos

- WinPC-NC

- ShopBot MTC

- Lynx Otter o

Is GRBL ok?

Thanks.

-

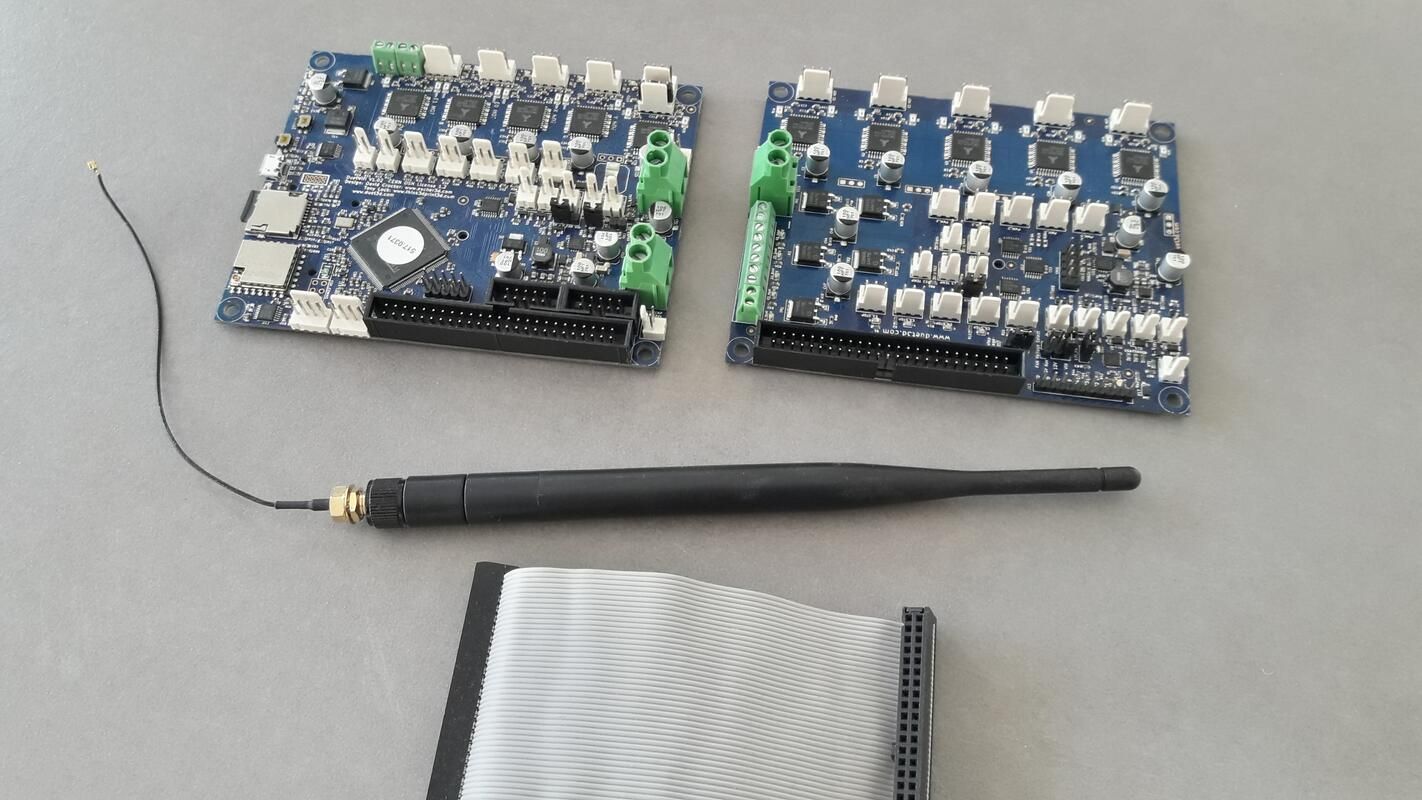

Selling Duet2 Wifi, Duex5, PanelDueposted in General Discussion

Hi!

As I switched to a Duet3 Mini for my FLSUN SR, I'm selling:

- 1x Duet2 wifi board (wifi module has external antenna): 80€

- 1x Duex5 expansion board: 60€

- 1x PaneldDue Controller + 7" screen and custom enclosure: 50€

(only to Europe).

-

RE: Early laser filament monitorposted in General Discussion

@droftarts if you look at the Laser filament monitor doc page, the first picture shows a v1.2 PCB

Thanks for the infos and the link to the indirect mod!

-

RE: Early laser filament monitorposted in General Discussion

I have a v1.2, not a v1.7; is it ok?

Does it work with 3.3V, like recent sensors? I don't have any free input with 5V power supply.

The modified version could be interesting...

-

Early laser filament monitorposted in General Discussion

Hi!

I still have one of the early laser filament monitors, using direct reading, with a PCB rev. 1.2, and I would like to know if it is still supported on a Duet3 Mini 5+?

I just want to use it as a runout sensor, and maybe as jammed sensor if it works reliably... What is the basic config (M591) for such use case?

Thanks,

-

RE: Configure RRF for a delta printer (FLSUN SR)posted in General Discussion

@dc42 Thanks! I do have a Z-probe.

-

RE: Configure RRF for a delta printer (FLSUN SR)posted in General Discussion

@droftarts Thanks for the drawing!

What accuracy (%) is needed for the different values?

-

Configure RRF for a delta printer (FLSUN SR)posted in General Discussion

Hi!

I'm configuring RRF for my FLSUN SR, and I'm not sure to understand the different values used by the M665 command... Is there a drawing showing how these dimensions are measured?

I found config files on 2 threads in this forum, but values seem to be the default ones generated by the online tool, and do not match the printer.

Thanks,