Some infill not reaching walls ?

-

Since the issues do not happen to print walls, tops or bottoms, why would speed/acceleration and jerk affect infill but not walls ?

-

@jens55 said in Some infill not reaching walls ?:

can you suggest a Linux compatible gcode viewer ?

I've only every used the slicers viewer or online web viewers. There's a few out there to choose from. I usually just google gcode viewer and try a few.

Retraction at layer change is off, combing is off, minimum extrusion distance window is 6.5 mm

Turn on retraction at layer change. With infill first, and no retraction between layers, it would make sense that there's not enough pressure in the nozzle at the start of the infill line. For non structural parts this isn't really an issue since it's all internal. I'd also reduce the window from 6.5 to 2mm as it would seem you're losing pressure on your travels.

-

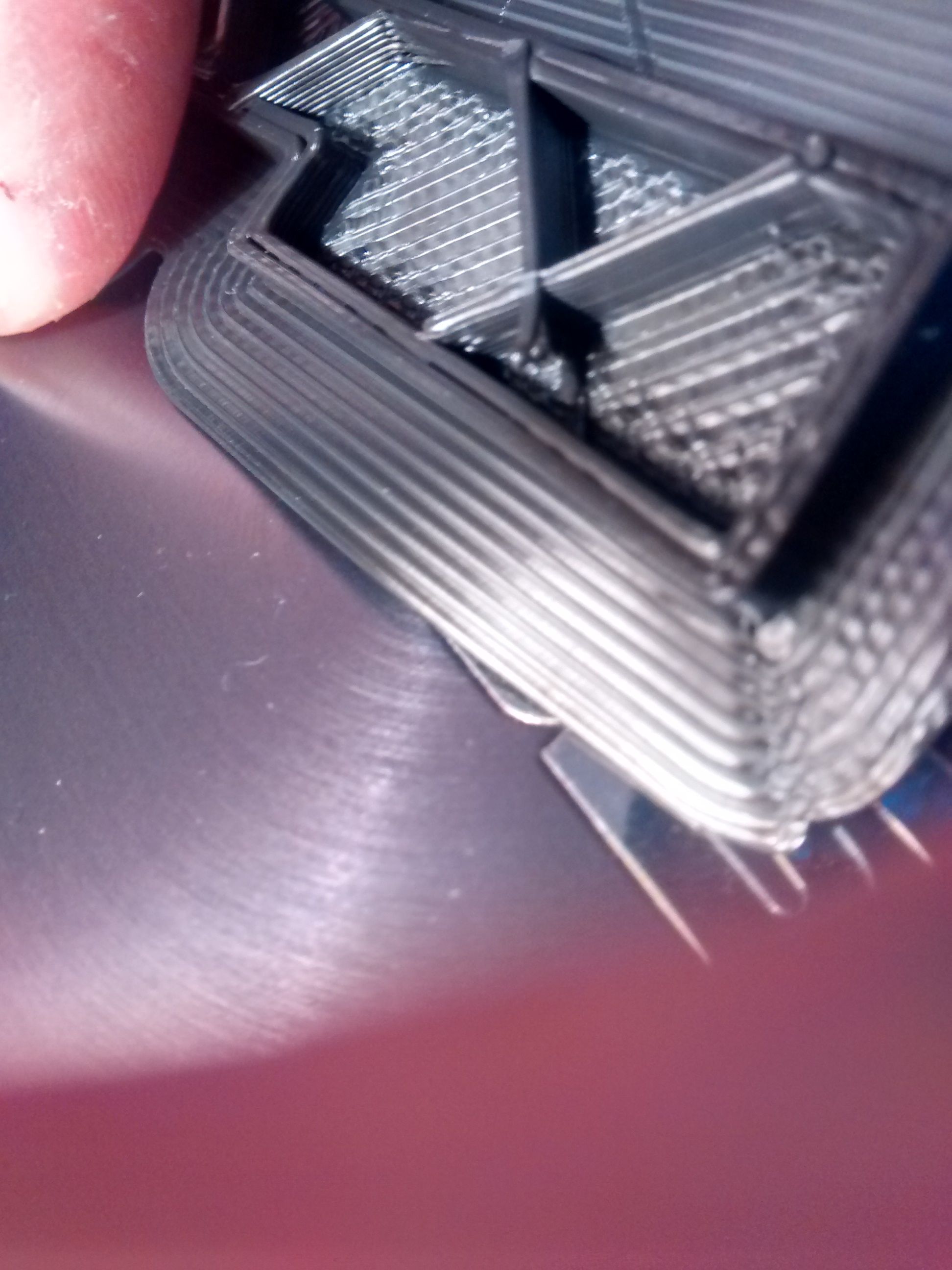

Turned on retraction at layer change, minimum extrusion window 2 mm, infill speed reduced to 30 mm/s, infill jerk reduced from 20 to 10, infill acceleration reduced from 3000 to 1000 and here is the result

The infill lines are cleaner and more defined as would be expected with the changes but you can see the big gap of wall to infill line

-

@jens55 said in Some infill not reaching walls ?:

big gap of wall to infill line

Can you post a saved .3mf from cura somewhere so I can see the entire cura settings and gcode preview?

Such a gap would seem to me that the infill overlap would need to be increased even further.

-

I may have a smoking gun here but not sure.

My bowden tube comes out of the extruder through a pneumatic connector, goes a while until it goes into a bowden connector /joiner (two pneumatic connectors back to back) and it then goes to the hot end.

Despite having little tube lock rings, there is noticeable movement of the bowden tube in the pneumatic connectors (three of the 4, no movement at the hot end). I'd say there is maybe close to 3 mm total movement between the three pneumatic connectors that move.

For some reason I think that pressure advance should take care of that situation but apparently it might not.

It is a good possibility that this issue also caused surface pockets that I previously posted about.

Question : Should pressure advance take care of issues with bowden tubes sliding in and out of pneumatic connectors to the tune of a mm for each connector ?

Bonus question: Are there specific pneumatic connectors that are known to hold the bowden tube rock steady ? (I am using cheap Chinese pneumatic connectors) -

@Phaedrux said in Some infill not reaching walls ?:

@jens55 said in Some infill not reaching walls ?:

big gap of wall to infill line

Can you post a saved .3mf from cura somewhere so I can see the entire cura settings and gcode preview?

Such a gap would seem to me that the infill overlap would need to be increased even further.

We cross-posted ... I think I should deal with the sliding bowden tube issue before bothering you with the .3mf file. What do you think ?

-

I have found some couplers in my spare parts stash that ought to work ... more news tomorrow when I have the couplers replaced and have tried if this fixes anything.

-

I'm not sure how PA would cope with the sliding. I suspect it would simply act as though the tube were longer than it actually is. But it could also mess with the timing of when pressure starts to build in the print head.

Getting that sorted out definitely couldn't hurt the situation.

Cheap chinesium stuff has its issues. Rarely get what you pay for imo.

If it doesn't help, post the .3mf. And your config.g for the complete picture.

-

Will do. Just printing another sample. The tubing slides a LOT less but still slides a bit. I might be forced to take the joiner out.

There seems to stil be a bit of a delay but I will try to tune it out with pressure advance.

As to how PA could (or should) help, it accounts for the filament compressing and relaxing as well as the tube movement as pressure is applied or removed.If nothing else, it's been an excellent learning situation and if I can't sort it out then it will be a good reason to abandon Bowden in preference of direct extrusion (after all, it's only money

)

) -

Yes I see what you're saying about PA accounting for it, but to me it feels like the slop for the slidinging coupler is different than just the fixed length of the tube and the compliance in that otherwise fixed system. I think it would be difficult to account for.

Have you tuned for PA at all? If so, it's obviously not having the intended effect.

I've heard people say good things about the capricorn tubing kits that come with their own couplers. So maybe that's a good quality option.

-

I use Capricorn but buy the tube in bulk without couplers because of the length I need.

I have tuned PA but it's obviously not doing it for me so will have to redo it ... especially now with the different couplers.It just ocurred to me that I had adjusted PA with a width of 0.8 mm and it is quite sensetive to the extruded width so it likely was way off. A job for tomorrow ...

-

Doing some more digging I found this little tidbit on https://duet3d.dozuki.com/Wiki/Pressure_advance:

"You may notice that when using pressure advance there may be a gap between the perimeters and the solid infill lines. To combat this you may need to adjust the infill overlap value in the slicer."

I think I will need to revise my understanding of pressure advance because of this tidbit from the same page:

"actual_extrusion_speed = requested_extrusion_speed + (K * current_extruder_acceleration)"

where K is the pressure advance setting.I suspect that you are correct and there is nothing in PA that would compensate for sliding bowden tube fittings.

-

@jens55 For info, I had the same thing with Capricorn tubing. When I measured it, the OD was slightly smaller than cheap no name PTFE tubing. I printed some thicker clips which helped a bit but in the end, my solution was to ditch the Capricorn and revert back to the cheap no name tubing. No more slippage.

-

Forgive me if I'm already repeating stuff that has already been covered but pressure advance is second to last, only to retract in the tuning sequence for me.

I've had this issue before. It appears as the bead not quite coming out in large enough quantities and there being tension in the bead as there is strength in the melt, it's not water like. You can reduce melt strength by getting the melt hotter, push out more material so that the tension isn't there, or go slower. The right answer is difficult to judge.

So my questions are:

- Have you calibrated e-steps with no loading on the extruder drive? Ie just drive filament through the extruder drive but not into a hotend.

- Have you picked a favorite temperature?

- Have you tested/checked for any need for linear or non linear extrusion correction? This needs to checked over the whole print speed range and done as accurately as possible. With a rule you are really looking at +/-0.5mm over 100mm at best.

- Have you done a square vase print to check wall thickness? Adjust filament diameter to get that correct. (I use firmware retract, so filamemt diameter is in the gcode)

- Now I look at pressure advance.

- finally check for retract and shoot for a value with a bit of comfort margin before stringing etc.

Then I play around a bit and discover my temps are too high or low and have to restart! The need for the linear and non linear extrusion correction are more complex with increasing bowden tubes and the closer you get to the throughput limits of the hotends. Likewise pressure advance for my E3D v6 with direct extruder is around 0.04 where as it was much larger with bowden. Around the 0.4 mark.

-

Isn't that funny .... pay a premium premium price for the finest and then decide to go back to the cheap stuff.

Thank you for mentioning that ! -

@DocTrucker said in Some infill not reaching walls ?:

- Have you calibrated e-steps with no loading on the extruder drive? Ie just drive filament through the extruder drive but not into a hotend.

yes

- Have you picked a favorite temperature?

210

- Have you tested/checked for any need for linear or non linear extrusion correction? This needs to checked over the whole print speed range and done as accurately as possible. With a rule you are really looking at +/-0.5mm over 100mm at best.

No, I have not read anything about that. Will do some digging tomorrow.

- Have you done a square vase print to check wall thickness? Adjust filament diameter to get that correct. (I use firmware retract, so filamemt diameter is in the gcode)

no

- Now I look at pressure advance.

- finally check for retract and shoot for a value with a bit of comfort margin before stringing etc.

Then I play around a bit and discover my temps are too high or low and have to restart! The need for the linear and non linear extrusion correction are more complex with increasing bowden tubes and the closer you get to the throughput limits of the hotends. Likewise pressure advance for my E3D v6 with direct extruder is around 0.04 where as it was much larger with bowden. Around the 0.4 mark.

It is between 0.4 and 0.5 for me but I will recalibrate in the morning to get that right.

Thanks!

-

I think the linear/non linear extrusion correction will help, or at least enlighten. As the extrusion rate goes up the actual quantity of extruded material can drop.

You need to look at your slicer settings and convert then from speeds/layer thickness/track width to volumetric throughput, and finally to filament speed. My tests for the E3D v6 tend to too out around 5mm/sec filament speed, but you are likely to be higher. Pick 5 or six filament speeds covering from the lowest to slightly bove the highest as your test points.

My process is now starting with for example:

G1 E100 F120

...measuring the amount of filament taken in and then repeating the test with both the speed and filament distance increased by a suitable fraction to try and account for any short fall. Repeat this until I have it close to 100mm filament used and then go to the next test point. The final correction fraction used is the value you are interested in.This process does take some time.

After all this is done you should see than solid infill is fairly consistant for short or long infil lines. You may find you need to wind back the extrusion multiplier a bit to prevent over extrusion. 100% dense leaves no room for error!

-

Bowden tube has been replaced and excess couplers removed, better couplers have been installed, pa has been re-calibrated and retract has been reduced to compensate for a much higher pa value.

Speeds have been reduced to avoid the possibility of problems arising from exceeding volumetric capacity of the Volcano hot end.

While things are improving with every step, there is still a significant lag (but less than before) between wall and infill in some portions on the infill. At the same time, I can see extrusion start at the instance of head movement beginning on things like the outer walls so I know that the printer is capable to squirt out material the instant the nozzle moves.

Update:

Out of desperation I have gone to an overlap of 100% and added a 1 mm3 of extra prime amount after retraction. All but one wall to infill joint is complete but the one eludes me. You can see the extra prime amount at the beginning of the extrusion but it is a good mm away from the wall.

-

You can see that the other 'arm' next to the failed arm just barely reaches the wall despite the 100% overlap.

-

Here is the gcode for layer 4 and 5 as well as the .3mf filelayer4and5.gcode [0_1577049965879_CFFFP_duet roof molding sample.3mf](Uploading 100%) [0_1577049998995_CFFFP_duet roof molding sample.3mf](Uploading 100%) CFFFP_duet roof molding sample.txt

Note tha the .3mf file was renamed to .txt to allow upload