Making an epoxy granite machine base

-

Yesterday evening I made a 800g batch of mix B with 15%w epoxy, 85%w white sand and 7g of blue dye. I did hammer the mix as best as I could (the mold opening is actually quite small and the different mold pieces flex open, so I can't go all sledgehammer on it though

).

).While mix A had a consistency comparable to what I have seen from the so called kinetic play sand, mix B is definitely wetter. Mix B was no so wet that I ran between my fingers but definitely wet enough to be a little runny and, well... cause by brain to flip the switch and think 'hey that's wet-ish'

.

.The epoxy takes about 2-3 days to cure to a usable level, so expect a new update around the weekend. But my gut feeling says that 15%w is going to be what I end up using for the actual pour. Since starting and seeing the mix A test piece I am thinking about closing the mold not just from the bottom and sides, but also from the top. Just to get a better surface finish, and possibly better clamping/compression. Looking at the images from the 1st post in this thread, it can be seen that just a couple straight pieces of wood can perfectly cover the remaining exposed area's.

-

hammering is cool but you really want to vibrate the $hit out of it and you want at least partial vacuum... just a simple vacuum cleaner and a plastic bag will let you get way better results than without vacuuming (having a decent pump is great but difference between nothing and vacuum cleaner is way bigger than vacuum cleaner to mega low vacuum pump

) ... the vibro is easy, you don't need super high frequences or anything special, if you have a sander that's enough or if you have biax (dremel, proxxon, whatever of those small ones) just attach a "bent drill bit" and let it run, attach to the mold or to the tray mold is in and let it run for a while .. combo of vibrator and vacuum will get you to the perfect mixture

) ... the vibro is easy, you don't need super high frequences or anything special, if you have a sander that's enough or if you have biax (dremel, proxxon, whatever of those small ones) just attach a "bent drill bit" and let it run, attach to the mold or to the tray mold is in and let it run for a while .. combo of vibrator and vacuum will get you to the perfect mixture  .. (and even if you don't go the "print abs, smooth with acetone" way if you have abs, you can coat your mold with cooking oil even if PLA, it will help a lot for easier removal

.. (and even if you don't go the "print abs, smooth with acetone" way if you have abs, you can coat your mold with cooking oil even if PLA, it will help a lot for easier removal  but you can check your hw store there are special "remover" sprays for the molds (no clue the real english word, we call them "odvajac" means "separator")

but you can check your hw store there are special "remover" sprays for the molds (no clue the real english word, we call them "odvajac" means "separator") -

@smece I tend agree with your points. On the other hand, as stated before: the mold is already completely printed (in PLA) and is not going to be entirely reprinted just for easier removal. It is a one time use mold after all.

I do not see how I can vacuum the entire mold and printer, keep in mind that the base will be cast in place on the machine. Also, while I did not try, I don't think that attaching a simple dremel or alike to a ~40 kg mold will do much useful. -

@Nxt-1 said in Making an epoxy granite machine base:

@smece I tend agree with your points. On the other hand, as stated before: the mold is already completely printed (in PLA) and is not going to be entirely reprinted just for easier removal. It is a one time use mold after all.

well for one time is irrelevant, you can lightly coat it with oil to easier remove it but even that you don't have to ... I was mostly thinking about the test pieces if you are going to do more of them so you don't need to make new mold for every test, for the final one it's irrelevant

I do not see how I can vacuum the entire mold and printer, keep in mind that the base will be cast in place on the machine.

huge garbage bags and vacuum cleaner .. works on a casted bathtub, should work on your printer too

just attach some temporary styrofoam blocks on any sharp bits that might tare the bag when you vacuum it

just attach some temporary styrofoam blocks on any sharp bits that might tare the bag when you vacuum itAlso, while I did not try, I don't think that attaching a simple dremel or alike to a ~40 kg mold will do much useful.

oh yes it will do a lot in combo with vacuum cleaner, it will shake all the bubbles out .. even the small dremel

... better if you have something bigger but even the dremel will do magic

... better if you have something bigger but even the dremel will do magicI'm not an expert or anything but my fam. had a "gheto manufacturing"

(no proper tools, everything bodged, wooden molds, everything as cheap as you can imagine ) for 2 years produced thousands of bathtubs, kitchen sinks, countertops etc etc out of that stuff and I helped from time to time so catched few things along the way ..

) for 2 years produced thousands of bathtubs, kitchen sinks, countertops etc etc out of that stuff and I helped from time to time so catched few things along the way .. -

Dear diary, today (well yesterday) I

fucmessed up.Well damn the 1st

Yesterday I went to town on the mold for the second test piece I made. As expected, getting the mold off was not easy, I was quite happy when the 1st mold piece started to give. To my surprise the EG cuboid split in two pieces, each half staying nicely in their side of the mold. My childish nature made sure that the 1st thing to come across my mind was, oooh touch it. So I did, and the EG felt dry but kind of sticky and not very stiff. All due to my impatience and to short drying time was my tough. Well damn (1).

Well damn the 2nd

That being that I was browsing on the webpage from the store where I got the epoxy from. By true coincidence I stumble across one of their video's about mixing epoxy and decide to watch it just for the fun of it. One of the things the host talks about is mixing ratio's, 100:43 ratio results in 100 units of part A and 43 units of part B. Immediately I realize that's different from my interpretation. My logic was to make 100 units in total you need 43 units of part B, leaving 57 units for part A. I get out my calculator, Matlab and drawing board and start solving some differential equations, contour integrals and invert some matrices. Low and behold the calculations are right, in my mixtures I used about twice as much part B as needed. Well damn (2).

It all comes together

That being that I continue watching the video and the host starts talking about wrong mixing ratio's. "Too much part A leaves you with a dry but not as strong result, while too little results in a sticky and gummy-ish part. Combining this info, damn (1) and (2) leads my to conclude that by using half as much part A as I needed by mixture was way to gummy (and indeed sticky), therefore it split in two while releasing it. I assume the 1st test piece survived because the lower percentage of epoxy in the EG maybe reduced the effect, but I don't know that for sure.

After all this, it is safe to say that my two test pieces are not very representative. On the other hand, I do feel like I have got a decent idea of how the material feels and what epoxy/sand ratio's are viable. So I don't think I am going to print a new test piece mold for more experiments before doing the actual cast.

-

Ouch. Glad it was a test piece.

-

Also make sure you look at the right mixture ratio. The ratios by volume and by mass are slightly different. I prefer mixing by mass.

I normally use 2 mixing containers for a batch. Weigh and pour A and B in container #1, mix, thoroughly scrape the bottom and sides, mix, pour in #2, mix again, and then process the epoxy.

For the mold release: I use a mold release wax. A small container is not expensive, lasts a long time, and gives a shiny surface. If you are not willing to invest in that, silicone spray or a thin layer of vaseline/petroleum jelly will work too.

If you can design some features in your mold where you can apply compressed air: that will help tremendously too. A simple hole plugged with a drop of hotmelt or thick grease is all that is needed.

-

Trouble with silicone spray is that you'll more or less never get it off something you might later want to bond to, and being aerosol it get to places you'd never think to cover.

-

All true, which is why mold release waxes and PVA-based release agents exist. It does work though.

-

Mini update, the mold is finally assembled and 95% ready to use. I still need to place the DIY threaded inserts for the rubber leveling feet in the mold.

The idea is to rest the printer on the center piece of the mold. And then fill the mold, compact etc. When I am happy with the filling of the mold, I place the three top cover pieces and screw them down to the rest of the mold. In hopes of getting a little squeezing action from the top as well, and a smooth(er) top surface finish.

@smece I do think I am going to coat the black mold surfaces with some cooking oil or whatever else I have laying around

.

.The plan is to do the casting during the weekend. That's what I said last week too, so we will see

-

@Nxt-1 Saw this and thought of you... https://hackaday.com/2020/02/12/concrete-solder-squid-is-a-solid-solution/

In the video, he uses a sander to provide some 'jiggle' to settle the mix. I'd also follow @smece advice https://forum.duet3d.com/post/131047 about getting some vacuum (even partial is good) by putting it in a bin bag and connecting up a vacuum cleaner; have you ever used those vacuum bags for clothes storage? Even with a vacuum cleaner, they draw out a huge amount of air. Though you may have problems with the mix being sucked into voids that you actually want to keep clear, so you may have to get creative. Both shaking and vacuum will improve the surface finish more than any other technique, and give you a flatter surface. Covering the mold and filling up to the top won't, because air bubbles get trapped, and as the mix dries it will shrink away from the top surface. If the top surface is the most important to get flat and nice (sharp corners), turn the mold upside down.

I've only done a small amount of concrete casting (some crazy-shaped flower pots), and a long time ago, but that's what helped get a reasonable finish with a pretty rough mix!

Ian

-

Ideal is to degas resin in vacuum and cure it under pressure; I wouldn't want to cure it under vacuum unless you go all the way to vacuum infusion.

-

@bearer I suppose I was thinking more of concrete casting than epoxy/granite.

Ian

-

Last Sunday was finally the big day. Oh and warning, picture heavy post

Prep

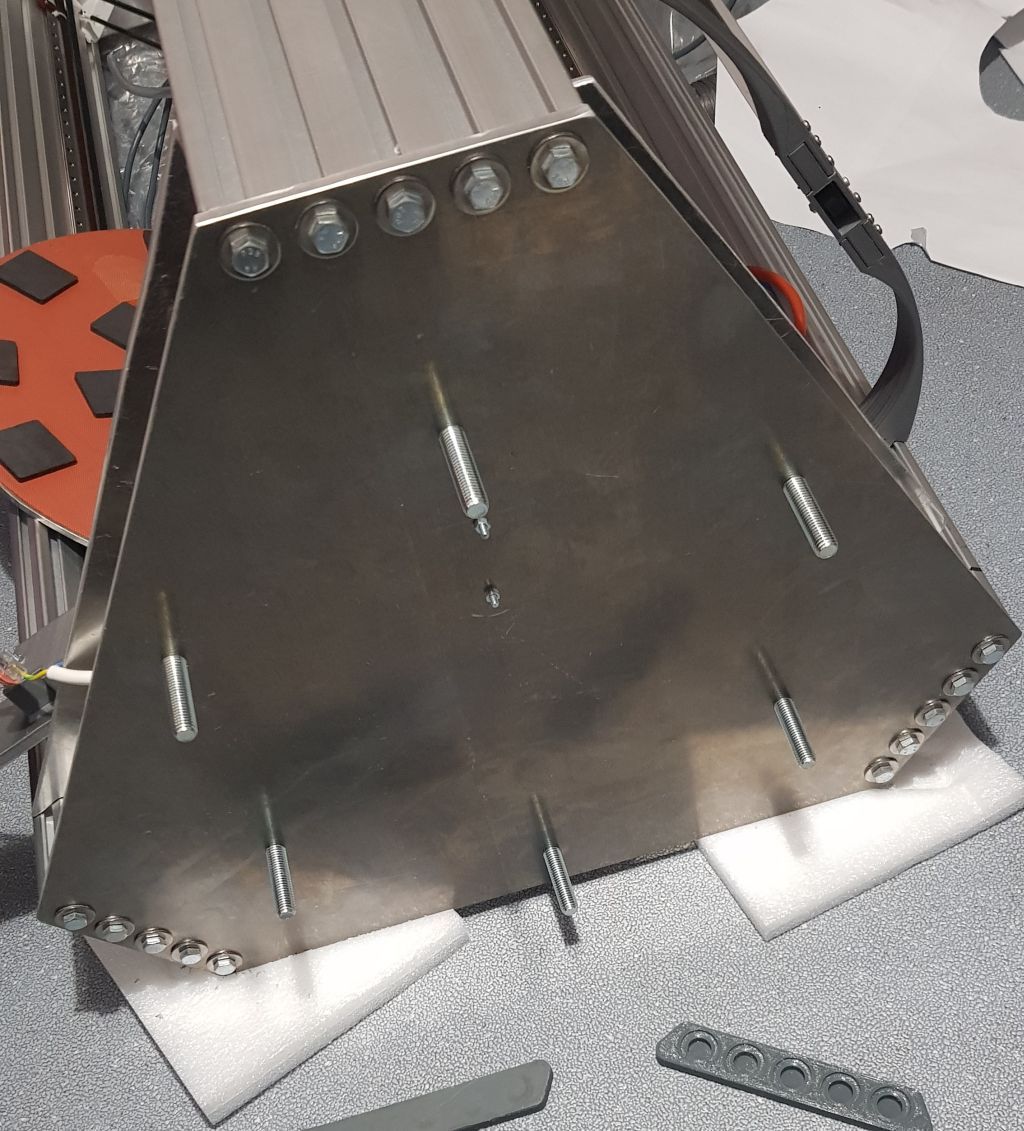

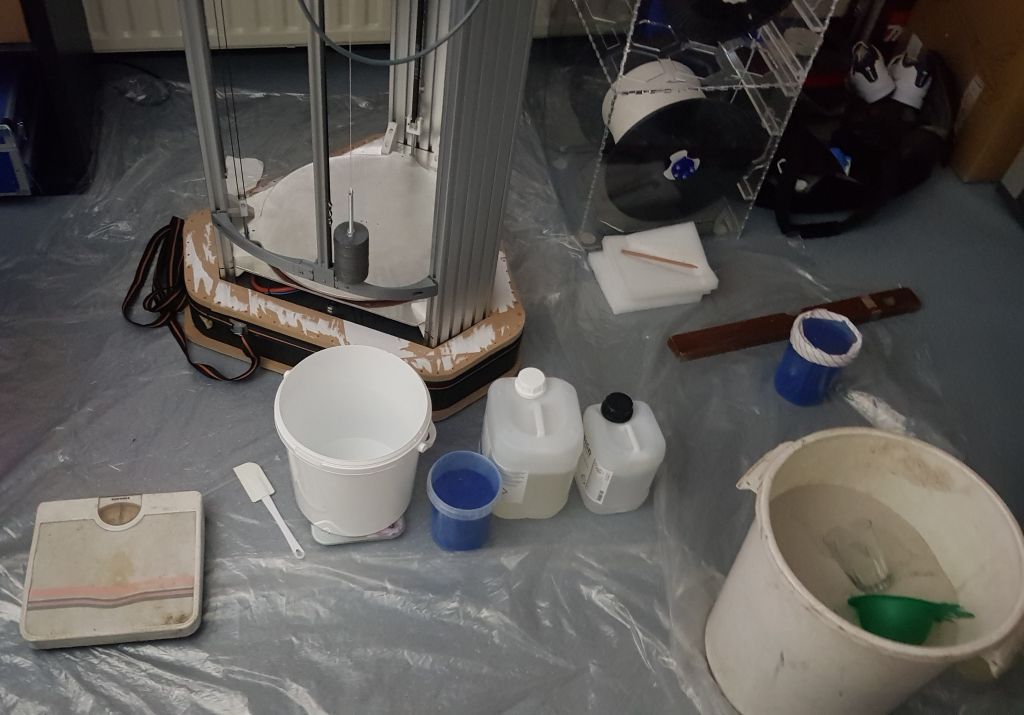

I started by drilling some d10mm holes in the bottom plate of the printer to allow M12 threads to be tapped. Six bolts were screwed in downwards, purely to have some extra surfaces where the epoxy can adhere to. (picture 1) Then followed a quick test fit with the empty mold and prepping my work area. All materials and tools, check. (picture 2)

Epoxy mixing

Time to start mixing. I ended up using a 15%w epoxy 85%w white sand mix. It might be interesting to note that the epoxy I used is, according to the seller, optimized for large pours. This means slow cure (180-240min working time and 3-7 days for a full cure) and low viscosity when mixed. I chose this epoxy because it gave me enough time to mix all the material I needed and I believe in this application low viscosity is preferable.

Seeing what mixing bucket I had available and the expected weight of the mixture I planned split up the mix into five batches of about 7,5kg each. Each batch started with measuring epoxy part B, then part A gets added to that and both get mixed thoroughly. Next up the sand gets added and the batch is mixed thoroughly again. Finally, about 50g of blue pigment is added and the mixture is mixed thoroughly one last time. Mixing each time ensure the previous step is always extra well mixed. Also, adding the pigment last and mixing it again makes for a good indicator of how well you mix. If the batch is nice a equally blue, you're

goldenblue.Casting

The mixture has a wet-ish sand texture with a good hint of sticky. If you want can more or less pour it, but it in all practicality it's to viscous to pour. Therefore, I just scooped a handful at a time and dropped it in the mold. As the printer was already in place (way to heavy to mess with lifting it on the mold during the casting) and the gap between the printer and the side of the mold is only about 35mm, using my hands to push the epoxy around seemed a decent way of working.

Due to the limited space around the mold and tiredness setting in at the moment I did not really compact the mixture when inside of the mold, except for that which I could to with my hand. Once the mold was completely filled, I added some extra mix on top before closing the mold up with the top wood pieces. I did this so that hopefully the clamping force did a small part in compacting the mixture.

Sadly, due to the potency of the pigment used it did not risk taking out my phone to snap some pictures while casting. Picture 3 is from when the mold was closed up.

Misc

In the previous post you can see the round center piece of the mold. This part was added one, to have somewhere the printer can rest on while casting and two, to save epoxy. Going in, I knew I would be a little short on mixture with the quantity of epoxy that I had bought. Therefore, I dimensioned the inner piece so that I would end up with roughly 2kg of spare EG mix. Picture 4 shows what was left over after casting, I have not weighed it yet but I believe it's between one and two kg of EG.

I made around 46kg of EG mix in total and it took me just about four hours to do the job. As I am writing this I also realize I did not coat the mold sides with oil, as I had planned. I guess opening the mold will be interesting.

Now the long wait for the EG to cure hase begun. I certainly hope it gives a decent result, just being pretty to look at if nothing else.

1

2

3

4

-

Looks like the demise of a smurf or two, but fingers crossed for the end result. Good call on the slow cure epoxy, keeping the exothermic reaction under control is much more manageable.

-

@bearer said in Making an epoxy granite machine base:

Looks like the demise of a smurf or two, but fingers crossed for the end result. Good call on the slow cure epoxy, keeping the exothermic reaction under control is much more manageable.

I will not disclose what the exact type of dye I used, nor where I got it from

-

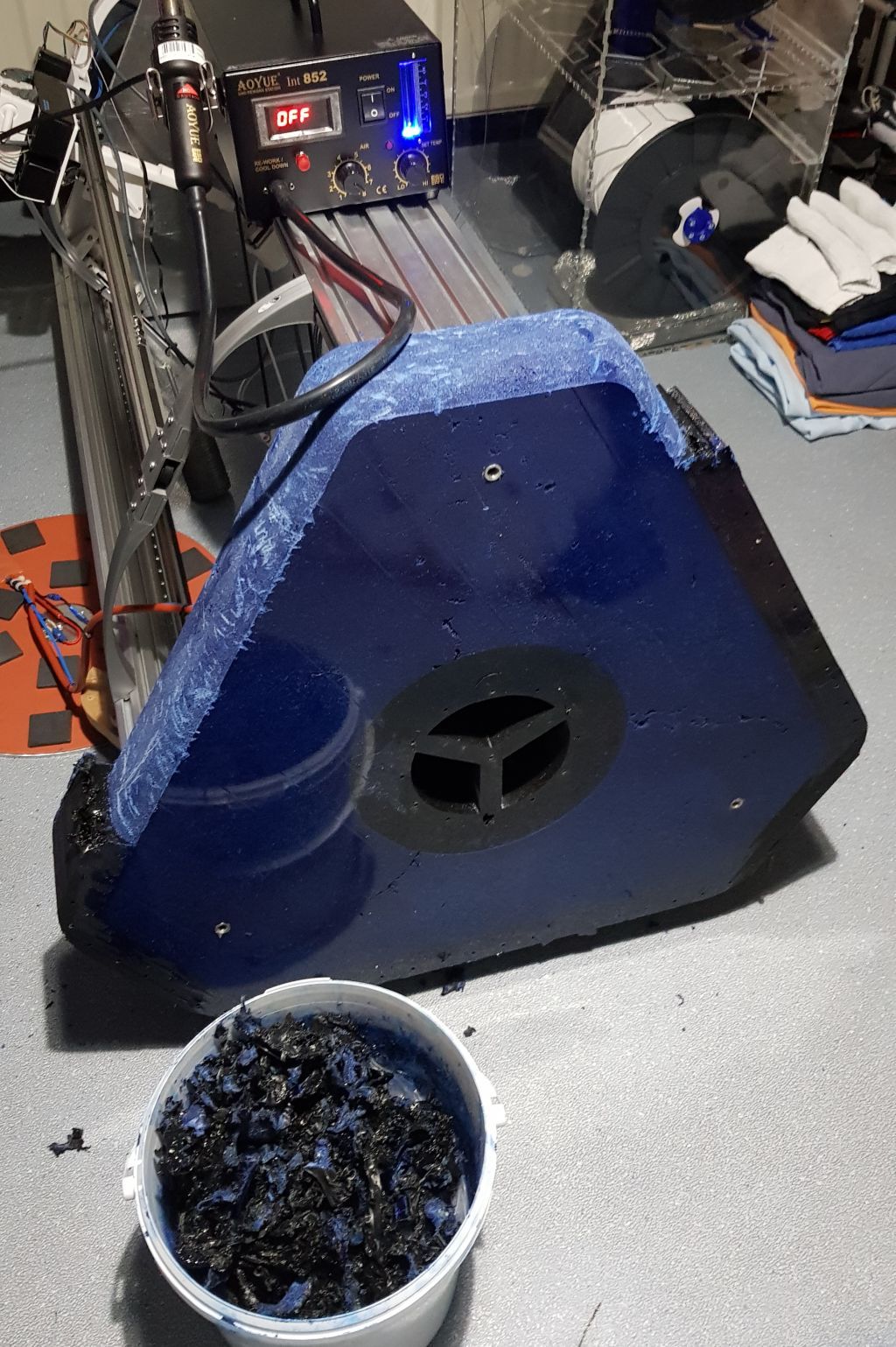

Time for a quick update. I started opening the mold on Wednesday evening by removing the top mold pieces and continued on Thursday with the removal of the bottom wood plate. Removing the wood was not to hard once all the screws were out and some light percussive maintenance was applied

Removing the printed walls of the mold is another story though.

@Nxt-1 said in Making an epoxy granite machine base:As I am writing this I also realize I did not coat the mold sides with oil, as I had planned. I guess opening the mold will be interesting.

Long story short, I am now removing the mold slowly by heating it with my hot-air rework station and pulling piece by piece off with a set of pliers. The process is painstakingly slow, but in the end I do end up with a clean and intact molded base, so you won't see me complaining to much hehe.

-

nothing that you can't rub out with a smurf dipped in some lapping compound;)

looking forward to seeing how it handles, thanks for sharing

-

In the end things never work out exactly as planned. It never has, and it never will. Just live with it. But it sure looks nice with the chopped smurf in it! Must have been royal smurfs too, those have blue blood.

For the next epoxy granite or composite project: get some mold release wax and PVA. I use these:

https://www.carbonwinkel.nl/los-oplosmiddelen/pva-film?hoeveelheid=250_ml_fles

Can be found cheaper also.

-

@Nxt-1 said in Making an epoxy granite machine base:

This means slow cure (180-240min working time and 3-7 days for a full cure)

That also spreads the exotherm out over time. I've seen very hot epoxy ruin molds many times...

Anyway, looks MASSIVE. I love it!!!