Heightmap lost adjustments of G32 ...

-

1.2.2020, 16:11:06 G29

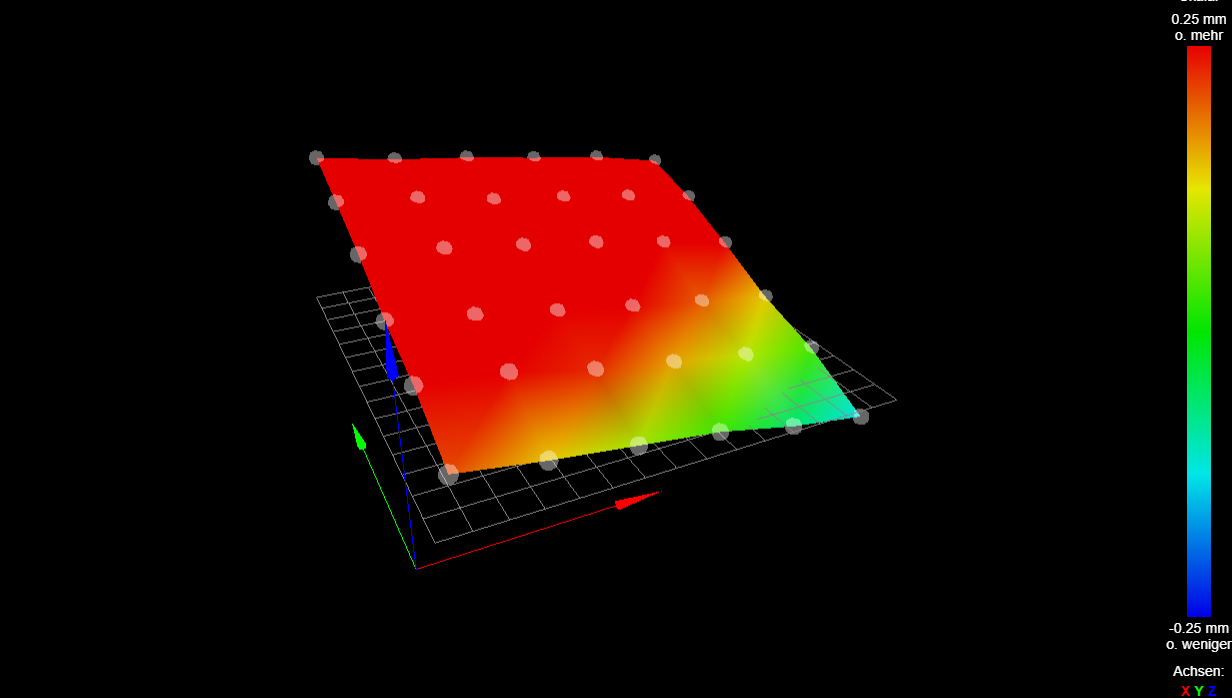

36 points probed, min error -0.125, max error 0.820, mean 0.377, deviation 0.242

Height map saved to file heightmap.csv

1.2.2020, 16:09:29 G32

Leadscrew adjustments made: -0.313 -0.129 -0.144, points used 3, deviation before 0.202 after 0.000

1.2.2020, 16:08:51 G32

Leadscrew adjustments made: -0.179 -0.097 -0.158, points used 3, deviation before 0.143 after 0.000

1.2.2020, 16:08:12 G32

Leadscrew adjustments made: -0.231 -0.135 -0.178, points used 3, deviation before 0.180 after 0.000

-

@Tobs94 said in Heightmap lost adjustments of G32 ...:

Leadscrew adjustments made: -0.313 -0.129 -0.144, points used 3, deviation before 0.202 after 0.000

1.2.2020, 16:08:51 G32

Leadscrew adjustments made: -0.179 -0.097 -0.158, points used 3, deviation before 0.143 after 0.000

1.2.2020, 16:08:12 G32

Leadscrew adjustments made: -0.231 -0.135 -0.178, points used 3, deviation before 0.180 after 0.000not that easy to see a trend but the deviation seems to be increasing, suggesting that your motor cabling does not correspond to the points defined.

You must use the M671 command to define the X and Y coordinates of the leadscrews. The M671 command must come after the M584 command and must specify the same number of X and Y coordinates as the number of motors assigned to the Z axis in the M584 command; and these coordinates must be in the same order as the driver numbers of the associated motors in the M584 command

-

i checked that for 100%

was testing and swaped front left and rear mid and now the test really starts to get bigger differences

-

@Tobs94 said in Heightmap lost adjustments of G32 ...:

was testing and swaped front left and rear mid and now the test really starts to get bigger differences

there are 6 different posibilities to adjust 3 wires.

-

@Tobs94 First, if you have not done so, update your firmware to RRF 2.05. https://github.com/dc42/RepRapFirmware/releases/tag/2.05

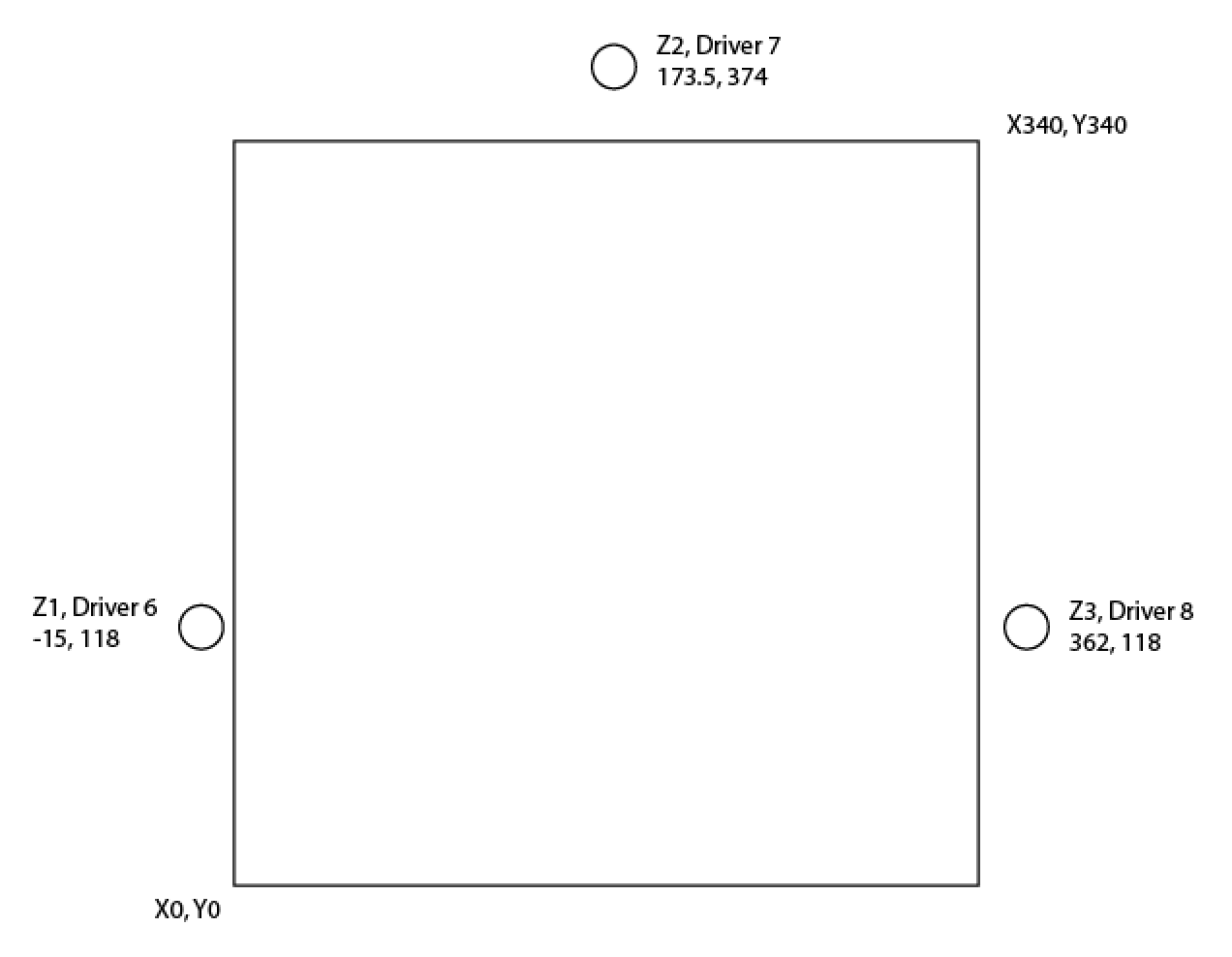

Then, check your Z motors are connected to the correct drivers. From your config.g:

M584 X0 Y1 Z6:7:8 E3 ; set drive mapping M671 X-15:173.5:362 Y118:374:118 S4 ; leadscrews at rear left, front middle and rear right ... ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X340 Y340 Z300 S0 ; set axis maximaGives:

Does this look correct?Ian

-

Yes that is exactly how it looks like.

-

7.2.2020, 15:44:15 G32

Leadscrew adjustments made: -0.141 -0.114 -0.166, points used 3, deviation before 0.133 after 0.000

7.2.2020, 15:43:27 G32

Leadscrew adjustments made: -0.138 -0.151 -0.140, points used 3, deviation before 0.144 after 0.000

7.2.2020, 15:41:24 G32

Leadscrew adjustments made: -0.069 -0.167 -0.206, points used 3, deviation before 0.141 after 0.000

7.2.2020, 15:40:40 G32

Leadscrew adjustments made: -0.133 -0.130 -0.066, points used 3, deviation before 0.122 after 0.000

7.2.2020, 15:39:26 G32

Leadscrew adjustments made: -0.349 0.038 -0.080, points used 3, deviation before 0.176 after 0.000

7.2.2020, 15:38:36 G32

Leadscrew adjustments made: -1.094 0.434 -0.084, points used 3, deviation before 0.524 after 0.000

7.2.2020, 15:37:52 G32

Leadscrew adjustments made: -2.909 2.198 -0.556, points used 3, deviation before 1.563 after 0.000still the same problem.. made me so mad. there must be 1 fault anywhere.

(Next Problem my Fan is now always on and they did not get shown on Web Control after update)

Thanks for help

-

and my Stall detection did not react anymore since update. No Change between -60 and +60

-

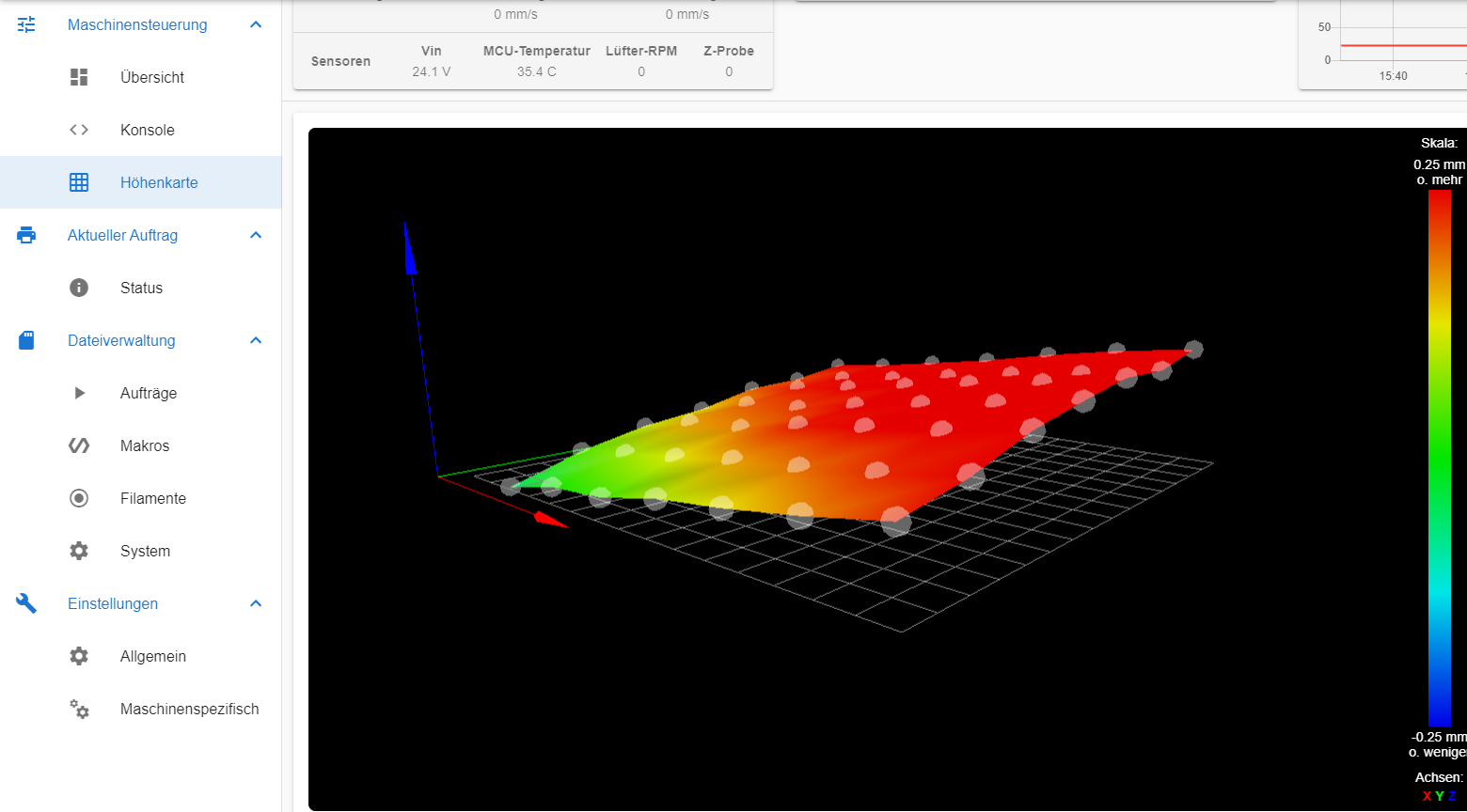

@Tobs94 .. I have a similar result, if i use z- axis AND bed compensation in combination. i have a double z-axis configuration.

if I run G29 only the bed don't have this "z-delta", ...its not "crooked"

if I run the Z-axis calibration more often ( 3 times) the results are better but not as expected.

this is my bed.g

T0 G10 P0 S180 ; Set extruder temp (tool 0) M140 S60 ; Set bed temp M116 ; Wait for temps to be reached G28 G30 P0 X05.0 Y140 H0 Z-99999 G30 P1 X290 Y140 H0 Z-99999 S2 G28 G30 P0 X05.0 Y140 H0 Z-99999 G30 P1 X290 Y140 H0 Z-99999 S2 G28 G30 P0 X05.0 Y140 H0 Z-99999 G30 P1 X290 Y140 H0 Z-99999 S2 G28 G29 -

@Tobs94 As @tobias_munich says, clear any mesh bed transform BEFORE running G32. Otherwise it's just levelling it to the mesh! Your bed.g:

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Jan 30 2020 17:41:07 GMT+0100 (Mitteleuropäische Normalzeit) ;M561 ; clear any bed transform ;G29 ; probe the bed and enable compensation G28 ; home M401 ; deploy Z probe (omit if using bltouch) G30 P0 X300 Y110 Z-99999 ; probe near a leadscrew G30 P1 X20 Y110 Z-99999 ; probe near a leadscrew G30 P2 X160 Y260 Z-99999 S3 ; probe near a leadscrew and calibrate 3 motors M402 ; retract probe (omit if using bltouch)Uncomment M561 in bed.g. This will clear the bed mesh before probing. You can also comment out or delete the M401 and M402, and it's a good idea to do a single G30 in the centre of the bed after running G32, to set Z datum. Run G29 after this to generate new bed mesh (or not, because it should be flat then).

Ian

-

@Tobs94 For M915 stall detection, you've copied the two examples from https://duet3d.dozuki.com/Wiki/Gcode#Section_M915_Configure_motor_stall_detection ... twice! It will be using the last M915 command,

M915 X Y S2 F1 R0.

For more detail on setting up stall detection, see https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homingIan