Filament size not consistent.

-

I'm trying to tune my max extruder rate on my new Hermera. It will start to extrude with a width of 0.4 mm but the it will grow to 0.75 mm

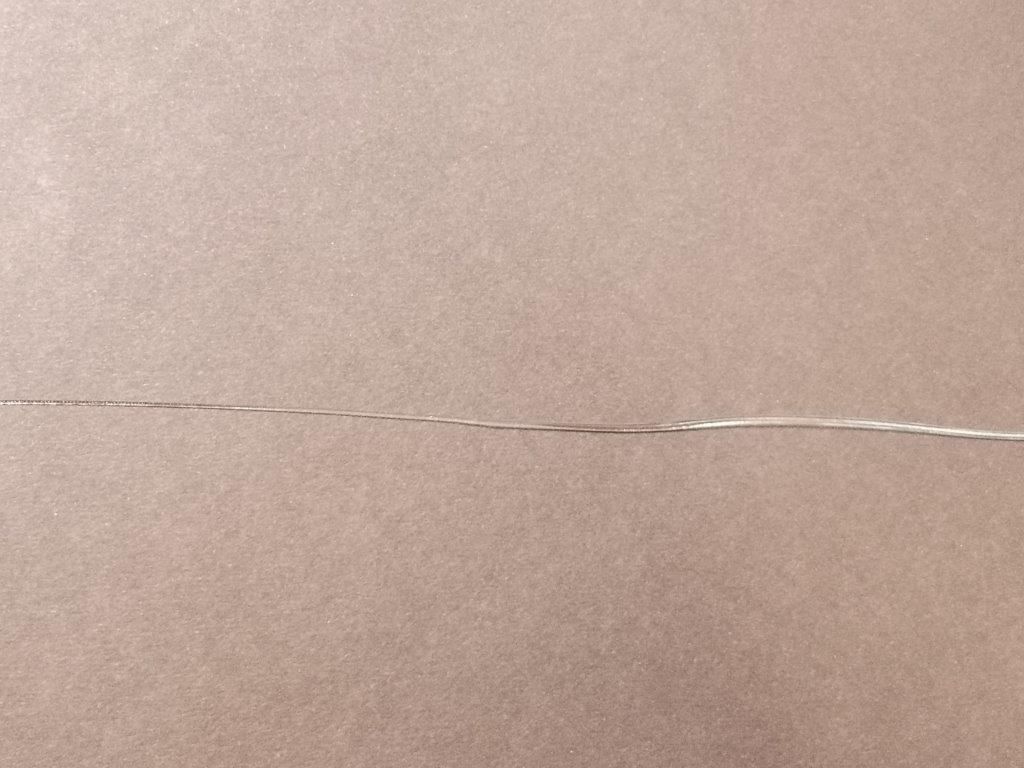

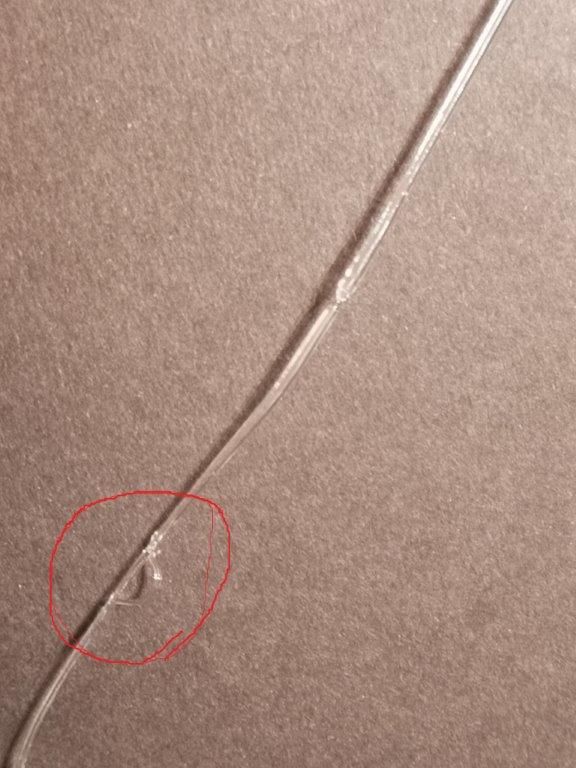

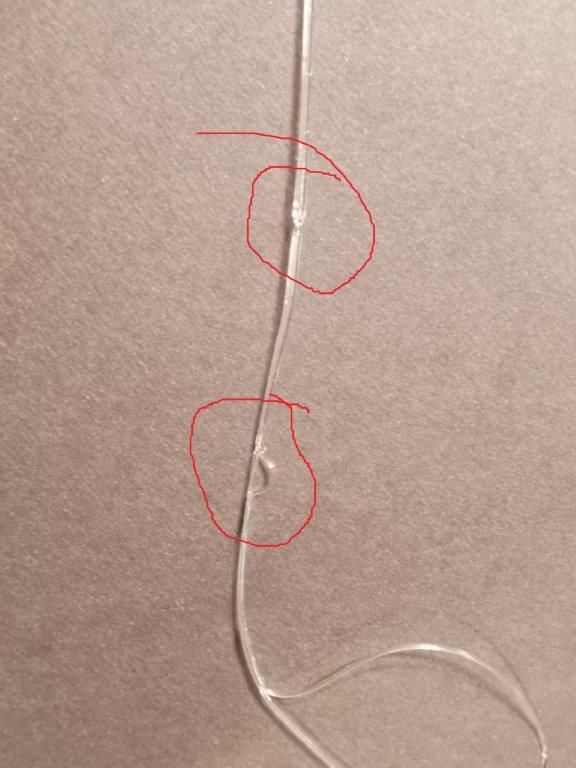

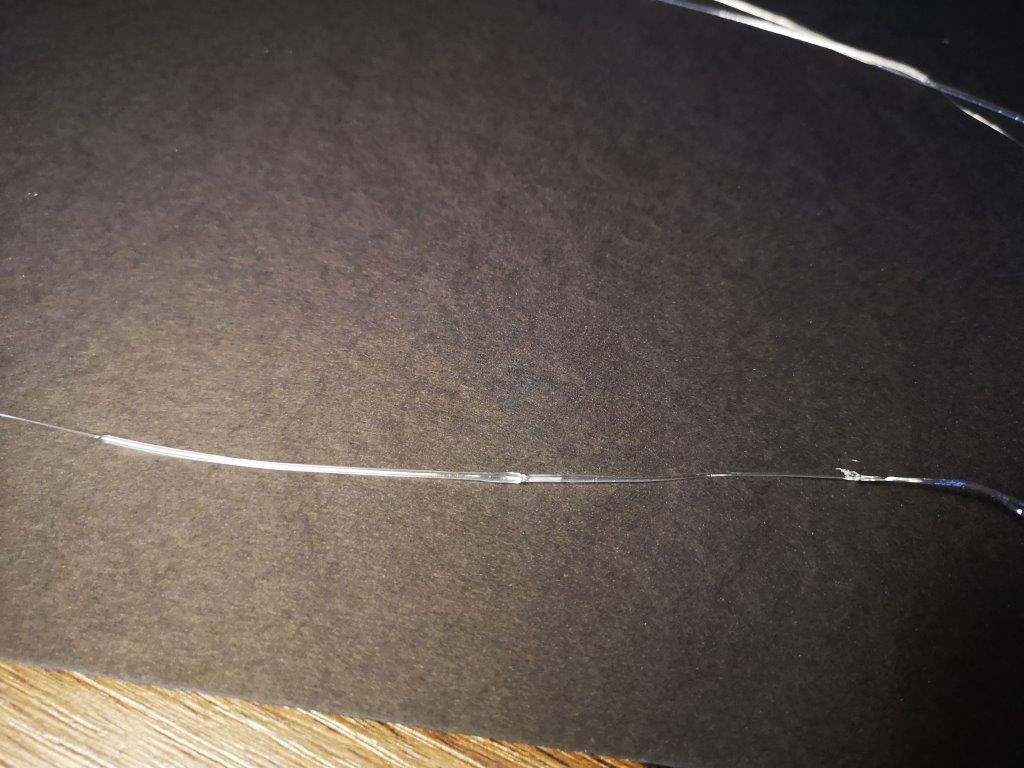

I started with G1 E50 F120 and in steps went up to G1 E50 F460. here are some photos.!

The first two are at the lower speeds while in the third and fourth, which are at G1 E50 F420 the is a loop which is always consistent and when it does the loop there is a clicking noise.

Not wondering if this is the Hermera or something strange in my setup.

Thanks for the help. -

When you are tuning for maximum extrusion rate, you are not concerned with the filament diameter as it exits the nozzle. There are a number of reasons why it comes out thicker (it doesn't actually come out thicker but mis-forms because it is in thin air).

All you need to be concerned about is the clicking which is what you want to avoid.

Maximum extrusion rate is just a tad below where you get the clicking.Having said that, F420 seems very slow. What material and what nozzle temperature are you using ?

Edit: Never mind the comment about slow, did the calculations and it seems about right (if my calculation is correct)

-

-

An average hot end can melt about 8-9 cubic mm per second, a Volcano hot end about twice that.

Volume is filament radius squared * pi * extrusion speed or (1.75/2)**2 * 3.14 * 420mm/60sec which is roughly 2.4 square mm * 420/60 or roughly 16.8 cubic mm per second. That means that either I screwed up on my calculation or you are running a Volcano (or similar) hot end. -

That sagging could be caused by too hot an extrusion temperature or not enough cooling with the fan. Try at 205 for extrusion temperature.

-

-

thanks Phaedrux yes I did see it but had tried a different test for max extuder speed. Just finished do that test and I was too high so now its almost right. Will try some new test to see what happens.

Jen55 I think your math is good but for sure 420 is too fast seeing the Hermera has a hotend like the Titan Aero only it is more direct.

-

@Synapsis said in Filament size not consistent.:

seeing the Hermera has a hotend like the Titan Aero only it is more direct

It doesn't matter how hard you push it, you're still up against the melt rate.