Configuring temp sensors

-

I am having issue's configuring the temperature sensors on RRF3. It a IDEX with two Slice thermistor's and a Keenovo silicone heater with a NTC Thermistor.

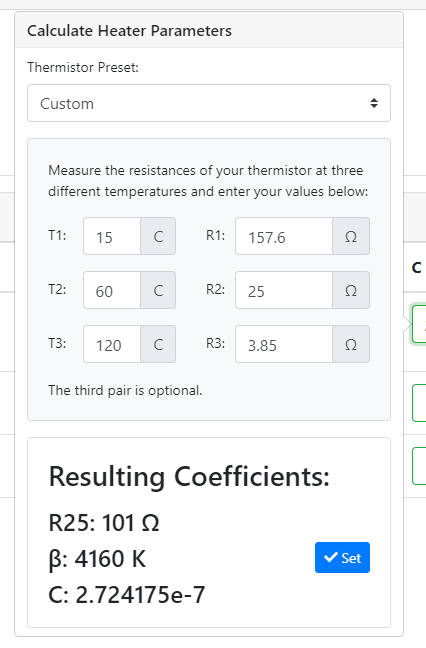

I used the temp table for the bed thermistor at 15, 60, and 120 degrees in the RR config but its reading -275 degrees currently.

I used the Slice preset for the hotend thermistors, they read 15 and 120 degress. It should be more like 30 degrees.

Can you see any issues with my configuration.

code_text ```M308 S0 P"bedtemp" Y"thermistor" T101 B4160 C2.724175e-7 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S2 P"e1temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M143 H2 S280 ; set temperature limit for heater 2 to 280C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit -

Working config with D3 and Pi, hot ends are E3D V6, whatever thermistor they send:

P.S. Not shown: My individual PID tuned heater models, because yours will differ.

; Temperature sensors M308 S0 P"0.temp0" Y"thermistor" T100000 B3950 A"Bed" M308 S1 P"1.temp0" Y"thermistor" T100000 B3950 A"HE1" M308 S2 P"1.temp1" Y"thermistor" T100000 B3950 A"HE2" M308 S3 P"2.temp0" Y"thermistor" T100000 B3950 A"HE3" M308 S4 P"2.temp1" Y"thermistor" T100000 B3950 A"HE4" ; Heaters M950 H0 C"0.out0" T0 ; Bed. H = Heater 0, C is output for heater itself, T = Temperature sensor (defined above) M950 H1 C"1.out0" T1 ; Heater for extruder out tool 0 M950 H2 C"1.out1" T2 ; Heater for extruder out tool 1 M950 H3 C"2.out0" T3 ; Heater for extruder out tool 2 M950 H4 C"2.out1" T4 ; Heater for extruder out tool 3 ; Further setup for bed M143 H0 S130 ; set temperature limit for heater 0 to 130C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 ; Fans for hot end cooling M950 F1 C"1.out6" M106 P1 S255 H1 T45 ; S = Speed of fan Px, Hxx = heater for thermo mode, T = temps for thermo mode. M950 F2 C"1.out7" M106 P2 S255 H2 T45 ; S = Speed of fan Px, Hxx = heater for thermo mode, T = temps for thermo mode. M950 F3 C"2.out6" M106 P3 S255 H3 T45 ; S = Speed of fan Px, Hxx = heater for thermo mode, T = temps for thermo mode. M950 F4 C"2.out7" M106 P4 S255 H4 T45 ; S = Speed of fan Px, Hxx = heater for thermo mode, T = temps for thermo mode. ; Fans for print cooling M950 F5 C"1.out3" M106 P5 C"PrintCool5" M950 F6 C"1.out4" M106 P6 C"PrintCool6" M950 F7 C"2.out3" M106 P7 C"PrintCool7" M950 F8 C"2.out4" M106 P8 C"PrintCool8" ; Tool definitions M563 P0 S"Tool 0" D0 H1 F5 ; Px = Tool number, Dx = Drive Number (start at 0, after movement drives), H1 = Heater Number, Fx = Fan number print cooling fan G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures(-273 = "off") M572 D0 S0.1 ; Set pressure advance on M563 P1 S"Tool 1" D1 H2 F6 ; Px = Tool number, Dx = Drive Number (start at 0, after movement drives), H1 = Heater Number, Fx = Fan number print cooling fan G10 P1 S0 R0 ; Set tool 0 operating and standby temperatures(-273 = "off") M572 D1 S0.1 ; Set pressure advance on M563 P2 S"Tool 2" D2 H3 F7 ; Px = Tool number, Dx = Drive Number (start at 0, after movement drives), H1 = Heater Number, Fx = Fan number print cooling fan G10 P2 S0 R0 ; Set tool 0 operating and standby temperatures(-273 = "off") M572 D2 S0.1 ; Set pressure advance on M563 P3 S"Tool 3" D3 H4 F8 ; Px = Tool number, Dx = Drive Number (start at 0, after movement drives), H1 = Heater Number, Fx = Fan number print cooling fan G10 P3 S0 R0 ; Set tool 0 operating and standby temperatures(-273 = "off") M572 D3 S0.1 ; Set pressure advance on -

@3DPrintingWorld said in Configuring temp sensors:

M308 S0 P"bedtemp" Y"thermistor" T101 B4160 C2.724175e-7 ; configure sensor 0 as thermistor on pin bedtemp

I think you mean T101000 in that command.

It's very hard to get accurate readings at low temperatures from high resistance thermistors such as the Slice. The one reading 15C at 30C I would say is within tolerance. You could use the M308 H parameter to adjust it. The one reading 120C probably has some moisture bridging the wires, or leakage between one of the wires and ground.

-

@dc42 In regards to the bed, I double checked the numbers but the configurator still spits out a "T101"

Not that I need accurate readings at this low temp but I do get them with this thermistor at ambit temps on my Marlin printer. I also have a spare thermistor and I swapped it out and it still reads the same 120 degrees.

-

I strongly suspect that the resistance table you are using is in Kohms, not ohms. So you should enter e.g. 157600 not 157.6.

-

@dc42 Your right, thats what the 100k must of mean on the top of the chart. Now its reading within range.

Also when I tried my spare trasducer, I swapped the wrong one.... I swapped the correct one and now all three are readying between 16-20c! -

Actually it was not the thermistor but the cable...