I just updated to RRF 3.2 and now I can not find the endstop status screen on DWC. Previously the status was shown under the settings menu in the "Machines-specific" screen but it is not longer shown since I updated firmware. Did it get moved somewhere?

Best posts made by 3DPrintingWorld

-

Cant find Endstop status on DWCposted in Duet Web Control wishlist

-

RE: Error: bad Command XXX W/RRF 3.2 and leveling issueposted in General Discussion

@gloomyandy That's good advice, I'll take it.

-

RE: Cant find Endstop status on DWCposted in Duet Web Control wishlist

Glad you can check status with the M119 but I'm confused as to why the visual status has been removed as it was a nice feature.

-

RE: Dual Y-axis endstop homingposted in General Discussion

It works perfectly, and is very slick looking while in action!

Here is my homey.g if anyone else is doing something similar. You can also find the entire configuration on my github, if it helps anyone out. Just give me some time to get it updated.

Up next, giving ends topless homing another try. But first, some multi-material prints as now my nozzles will now stay perfectly aligned.

Thanks for the help but I'll be back....

; homey.g

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X475 U-475 F1800 ;Rough home X and U axis

G1 H1 X475 ; home X axis

G1 H1 U-475 ; home U axis

G1 X-15 U15 F6000 ; go back a few mm

G1 H1 Y500 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y-5 F6000 ; go back a few mm

M584 Y1 ; Y-axis right side

M574 Y2 S1 P"ystop" ; Y-axis right side endstop Active

G1 H1 Y15 F360 ; move slowly to Y axis endstop once more (second pass)

M584 Y2 ; Y-axis Left side

M574 Y2 S1 P"e1stop" ; Y-axis left side endstop Active

G1 H1 Y15 F360 ; move slowly to Y axis endstop once more (second pass)

M584 Y1:2 ; Combine Y-Axis

M574 Y2 S1 P"ystop+e1stop" ; Y Double max active high endstop switch

G1 Y-5 F6000 ; go back a few mm

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning -

RE: Error: bad Command XXX W/RRF 3.2 and leveling issueposted in General Discussion

@Phaedrux neverminded, I found fallback procedure 3.

-

RE: Error: bad Command XXX W/RRF 3.2 and leveling issueposted in General Discussion

@martin7404 That is great news Martin!

-

RE: Error: bad Command XXX W/RRF 3.2 and leveling issueposted in General Discussion

@fcwilt At one point I tried that but I went back to having everything in the homeall because it really does save some time, epically considering that this printer has an additional U axis. It is really nice and clean though, maybe I'll revisit it once I get this mess figured out.

-

RE: Error: bad Command XXX W/RRF 3.2 and leveling issueposted in General Discussion

@Phaedrux I plan on moving to a new thread and only cover one topic, I just wanted to try a couple things before I do but I have not had the chance.

-

RE: Independently leveled Z axis Issueposted in General Discussion

@fcwilt Sorry, I should have said low current.

-

RE: Duex5 Endstop Issueposted in General Discussion

@dc42 said in Duex5 Endstop Issue:

It's not bad practice

Ok, good to know! I would consider this problem solved since I am not seeing any issues since updating to 3.2.2

Latest posts made by 3DPrintingWorld

-

RE: Tracing down a bad conductorposted in General Discussion

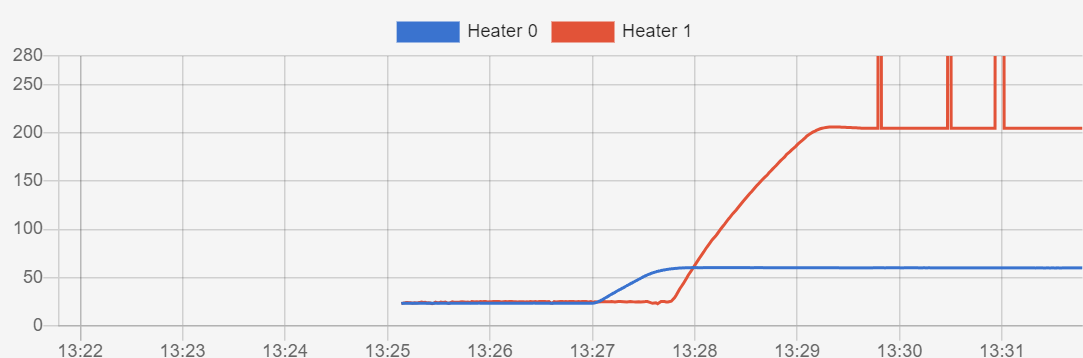

@dc42 I have not updated my firmware as its been working great, I was on 3.4 which must be why I did not get a report when I unplugged the connector. The temperature is showing 2000C when it spikes.

I took the wires out of the track and let them dangle so I could try to reproduce the short by manually manipulating the wires. Then my plan was to replace them but the spikes completely stopped. I put the wires back in the track and still no temperature spikes. Its so strange, if/when it continues I'll try replacing the wires. Its strange that it stopped all the sudden and that I could not cause the short by manually manipulating the wires.

-

RE: Tracing down a bad conductorposted in General Discussion

@Phaedrux Going back to my original question, I unplugged the two CAN wires and I get the same temperature spike until I plug it back in. As a result of this test, I think I can assume that this is not a thermistor issue but a short in the CAN bus wires. I'll replace these wires and see what happens.

If the controller is not communicating with the toolboard, does it not know? Why is there no error/alarm?

-

RE: Tracing down a bad conductorposted in General Discussion

@jens55 I would think if the short was in the thermistor connector, when I move the connector around I would also get the temperature spikes but I only seem to get them when running g-code.

-

RE: Tracing down a bad conductorposted in General Discussion

@dc42 Here is what the spikes look like. Moving the thermistor cable around does not seem to trigger it. I can only get it to trigger while running g-code. Would you get a short on a stationary wire, I understand the wires in the cable track.

Its been running great with the toolboard for over a year, would a grounding issue show up after this long? I also dismounted the board and I don't see how the mounting holes are plated, unless I'm missing something. Its a 1.2., should there not be some kind of metal around the holes?

-

Tracing down a bad conductorposted in General Discussion

I have a Duet 3 and a TLC 1 on a custom printer. I just started seeing hotend temperature spikes. I'm assuming its a broken wire but I'm having a hard time tracing down the wire. You would think that its one of the moving wires but since its the hotend temperature spiking does that mean that the bad wire is between the thermistor and the toolboard? Or would I also see the temperature spiking if there was a short in the power or Can wires?

-

RE: Changing Acceleration Midprintposted in General Discussion

Thanks for the help! It turns out changing M201 worked perfectly fine from the start. I expected to see a larger amount of ringing between accelerations but I was printing fast enough as I forgot to turn up perimeter under speed.

-

RE: Changing Acceleration Midprintposted in General Discussion

@fred-y That's really smart, I just put a dumb script in my slicer at layer height.

-

RE: Changing Acceleration Midprintposted in General Discussion

@phaedrux Thanks, that will make it easy to verify.

When searching the g-code the only M201 or 204 I find is the ones I inserted.

"The extruder holding it back", like its accelerations are not fast enough to keep up with the travel moves? I can increase it and try. -

RE: Changing Acceleration Midprintposted in General Discussion

@dc42 That's what I thought but does not seem to be working for me. I'm trying to increase the accel by 1000 every 25 layers starting at 2000.

Config

M201 X2000.00 Y2000.00 Z500.00 E600.00

Inserted on line 25 of gcode

M201 X3000.00 Y3000.00I also tried M204 like this.

Config

M201 X2000.00 Y2000.00 Z500.00 E600.00

Inserted on line 25

M201 X3000.00 Y3000.00

M204 P3000.00 T3000.00It does not look like its increasing, plus layer times are not decreasing. Is there a way to check the current acceleration setting?

-

Changing Acceleration Midprintposted in General Discussion

It is possible to change acceleration values for the X and Y axis during a print, either from the command prompt or by inserting it into the G-code? The goal is to change accelerations for a ringing test.