Understanding bed, nozzle and probe boundaries?

-

Hi, I need some help.

I did struggle a bit on my older printer as well but got it working at one time. Now I'm biting my own tale again. Probably because there is a simple fundamental misunderstanding.

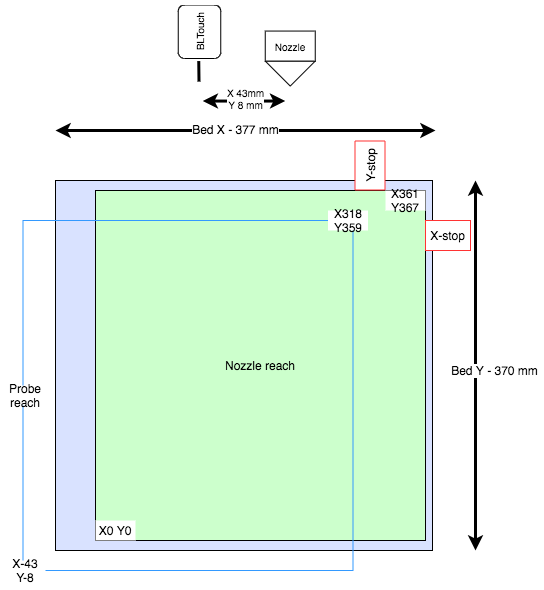

I'm struggling how to configure my Duet 2 and how to avoid probing outside the bed and/ probing as much area as possible.

Does the probe have it's completely own plane relatively to a (the) tool/nozzle.

I made an illustration to help my self as well. Editable draw.io diagram: https://drive.google.com/file/d/1HQhqSgb8IDBUko1jzIApC7QzK2Fqkr1x/view?usp=sharing

config.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Mar 19 2020 21:32:43 GMT+0100 (Central European Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Stians Ender 5 Plus Titan" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S1 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 M569 P1 S0 ; physical drive 1 M569 P2 S0 ; physical drive 2 M569 P3 S1 ; physical drive 3 goes backwards M569 P4 S0 ; physical drive 3 M584 X0 Y1 Z2:4 E3 ; drive mapping, two Z motors connected to driver outputs Z and E1 M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E396.38 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z240.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X400 Y400 Z400:400 E500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; dual z M671 X-31:384 Y184:184 S2 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X361 Y367 Z400 S0 ; set axis maxima ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"zprobe.in+zprobe.mod" H5 F120 T6000 A3 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X43 Y8 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X50:361 Y25:367 S30 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 150C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S275 ; set temperature limit for heater 1 to 275C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; System temp sensors M308 S2 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S3 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper ; Fans M950 F0 C"fan0" Q5000 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q5000 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q5000 ; create fan 2 on pin fan2 and set its frequency M106 P2 H2:3 L0.3 X1 B0.3 T30:60 ; set fan 2 value M950 F3 C"e1heat" Q9000 M106 P3 L2 X100 B0.3 S12 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first toolbed.g

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Mar 19 2020 21:32:43 GMT+0100 (Central European Standard Time) ;M561 ; clear any bed transform ;G29 ; probe the bed and enable compensation ; from https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors G28 ; home ;M401 ; deploy Z probe (omit if using bltouch) G30 P0 X25 Y175 Z-99999 ; probe near a leadscrew, half way along Y axis G30 P1 X375 Y175 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors ;M402 ; retract probe (omit if using bltouch) -

I inverted the XY probe offset!

Instead of G31 P500 X43 Y8 I should use G31 P500 X-43 Y-8.

Hmm, need to read the doc again.

-

The best way to maximize the mesh grid is to take your M208 as the bed surface, then add/subtract your probe offsets. That will give you the area for M577 that the probe can reach. Adjust it slightly so that you can get a whole number of points within it. Tip, if you send an M577 with a unreasonably high number of probing points it will suggest the actual maximum to you.