Nozzle probes off bed.

-

Alright, so the M557 would as far as you want on the low side because your probe offsets are to the low side, and on the high side it would only be able to reach as far as x110 - x60 and Y85 - y12

-

@Damien The easiest way to find the ideal M557 for me in practice is to just jog the print head around so that the probe is where I want it and take those XY coordinates.

-

Ok....I am still so confused!

So I took you suggestion about jogging head around to find what I can work with based on my mods.

As a result, my min/Max axis has changed.

Below is my config. What calculations should I use to figure out how to define the grid again?

Thank so much in advance!!

; Configuration file for Duet Maestro (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.3 on Sat Jun 13 2020 22:55:16 GMT-0500 (Colombia Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Damiens Ender 5 Pro" ; set printer name; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X64 Y64 Z64 E128 I1 ; configure microstepping with interpolation

M92 X320.00 Y320.00 Z3200.00 E747.59 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1500.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-110 Y-110 Z0 S1 ; set axis minima

M208 X105 Y92 Z300 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop; Z-Probe

M558 P5 C"!^zprobe.in" H5 A1 F120 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P200 X-60 Y-12 Z5.98 ; set Z probe trigger value, offset and trigger height

M557 X-110:110 Y-110:110 S10 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 A140.3 C627.1 D0.2 S1.00 V22.9 B0 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 A340.0 C140.0 D5.5 S1.00 B0 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F0:2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 -

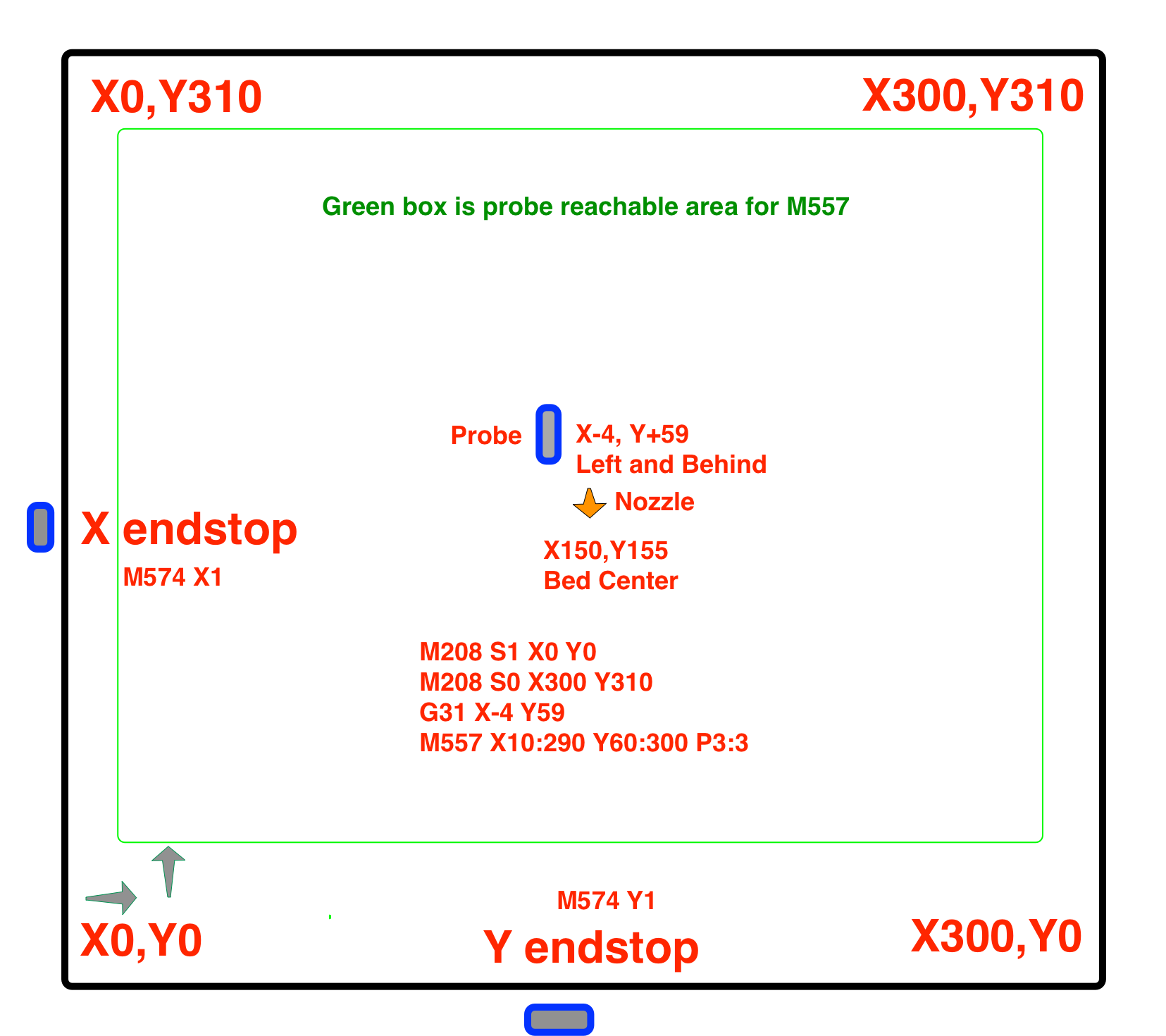

Maybe it would help if you created a diagram of your bed like this one.

By the way, 60mm in the x direction is quite a bit. Is that really the closest you can get the probe to the nozzle?

-

Thank you for this. I'll fill in and see if it helps. I'll post image if I still can't work it out.

In the meantime, here are some pics of my setup. With the Induction sensor I have, this is the closest I could get it...

-

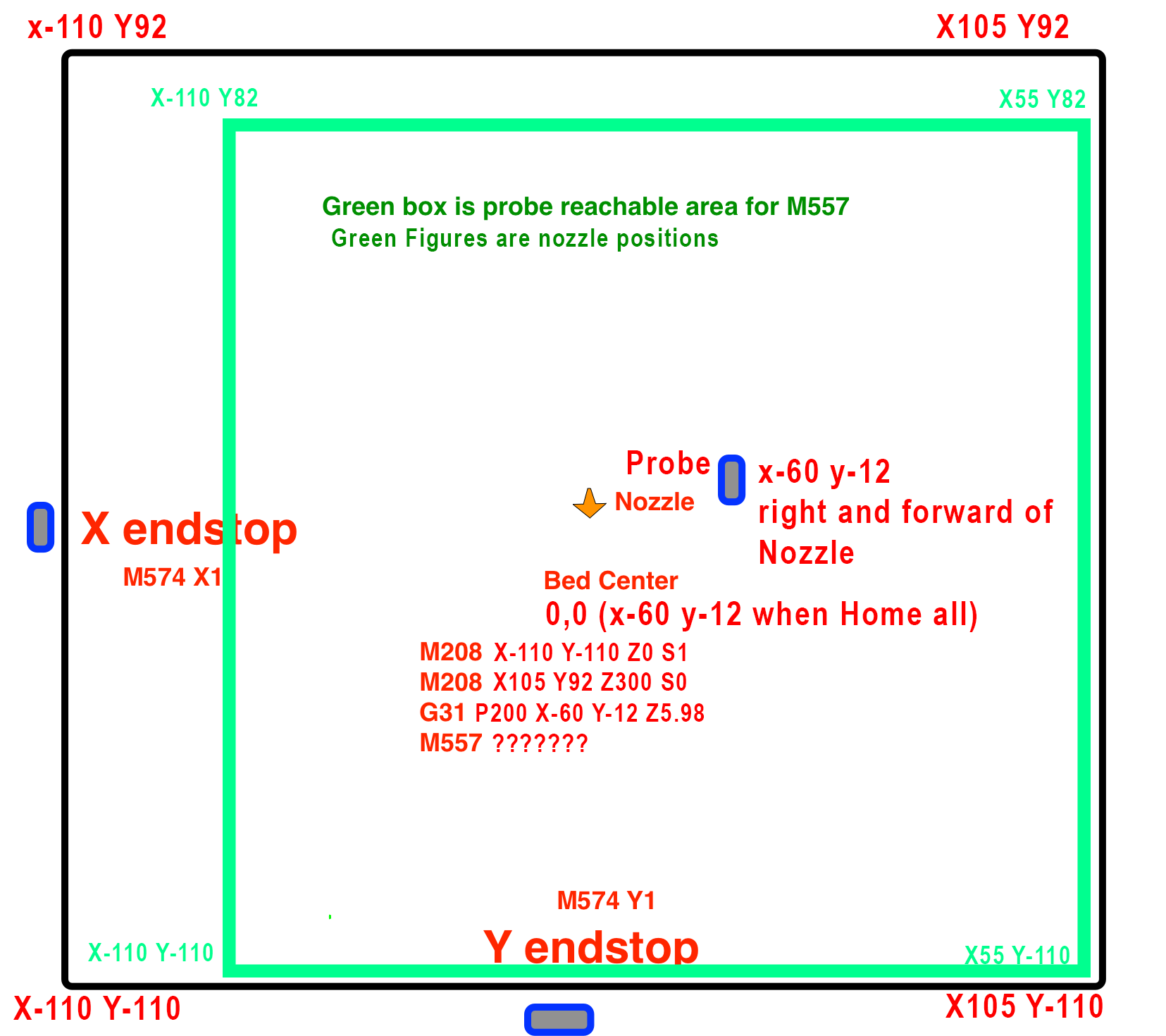

Ok, here it is....What do you think?

-

@Phaedrux When I input the ranges of the green the probe still goes over the edge. Any pointers?

-

What's the coordinate of the nozzle that keeps your probe on the bed?

-

@Phaedrux all the coordinates you see in the green are ones where the sensor stays over the bed. But, so some reason when I put my M557 x-110:55 Y-110:82 S10 other first probe starts at x-50 y-98. 🤨

Then it proceeds to keep probing until off the bed on the x axis, which I then have to emergency kill it.

-

Ok, I just tried adding the probe offset on one side of the green coordinates and minus’’Ed on the other and that seems to have done the trick.

So my coordinates for M557 is now X-170:-5 Y-122:94. Probing is perfect now.

-

@Phaedrux Before I continue, I wanted to say a big thank you for your help before! It's good to have people like you helping us all make the most out of our printers.

After all of the above, I have decided to make my origin back to its original place in the corner. I've decided this because I am not getting a good consistent squish across the various spots on my bed. Plus, I am not confident that the mesh on my bed that I got is correct. (See below)

I'm just about to redo my trigger height, but I have a question. In the guide(https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe), it calls for you to bring your nozzle to the center of the bed and do the paper test. Afterward, it asks you to begin your trigger height routine. BUT, here is my question...

Seeing as my probe offset is so far, isn't it a better idea to bring the probe over the same spot I did the paper check to make sure I have a consistent base height? Or, does the programming for the G29 somehow compensate for this?

Thanks in advance!

-

Answered in your other thread.