Delta printer twisting beginning of print

-

I recently replaced a RAMPS board on my Mini Kossel with a Duet 2 WiFi and have been slowly been dialing in the print settings. I'm at a point where I'm pretty happy with the print quality, but I'm seeing some layer shifting and a small amount of twisting right at the beginning of the print. There are some photos on imgur: https://imgur.com/a/Bo7vGKK.

The shift occurs at the layer when the letters first appear. Could it be high acceleration or jerk causing this? My acceleration is set to 1000 mm/s^2 and each motor is set to receive 1 A (they are 1.8 deg motors rated for 1.5 A). I used the stepper motor speed worksheet that I found linked on your website and set my print speed to 30 mm/s -- a value that I considered conservative. I also enabled jerk control in my slicer, which I believe is supposed to reduce the jerk, but this setting appeared to have no effect.

As for the initial twist, I'm not sure what could be causing that. My belts seem to have good tension, and I checked that the towers are straight and have even spacing. It's just the first part of the print that has that twist, so I'm not sure where to begin with this one. I find it strange that the print begins to straighten when the letters are being printed.

Thank you.

-

Are you using any mesh compensation or anything? What is in your config.g file?

-

Hi @bot. Thanks for your response.

I am not using mesh compensation. Before each print I run a 6-factor automatic calibration. The calibration probes six points around the edge of the bed and also the center point.

My config.g is here: https://pastebin.com/WgQBag6r.

-

What are the values given after the calibration is done? Can you perform a calibration and then show the results? IE the tower adjustments or radius adjustments and whatnot.

-

Here are the results:

G32 Calibrated 6 factors using 6 points, deviation before 2.437 after 0.000 M665 Diagonals 215.000:215.000:215.000, delta radius 107.333, homed height 247.759, bed radius 70.0, X 0.043°, Y -0.594°, Z 0.000° M666 Endstop adjustments X0.11 Y0.46 Z-0.58, tilt X0.00% Y0.00% -

I would say that the reason for the "twist" is that the calibration is detecting and correcting for the Y tower being at the wrong angle relative the other two.

Try setting the parameters manually to the ones that the calibration finds, but don't use the rotational adjustments -- set them to 0. Then see how the same print looks. Is it worse? Better?

Also, are you sure that your arms are all exactly 215 mm?

-

Thanks for the suggestions. I tried as you stated, to use the calibration results and to set the angular offsets to 0, but this leads to prints that don't adhere to the bed surface in all places. The bed does have a slight tilt to it.

As for the diagonal rods, I had measured them each as best as I could from the bearing centers. They each measured very close to 215 mm.

-

Ok. Is it 5 factor calibration that ignores the angles of the towers? Can you perform that calibration instead, so that you can determine yourself if your towers are angled instead of the calibration?

-

Thank you @bot. I tried four-factor calibration and confirmed that the tower angular offsets remained 0. Doing this got rid of the twist that I was seeing at the start of my prints, so thank you for suggesting that!

Here is how the print looks now: https://imgur.com/a/tJZK2xa. It's much more straight, but you'll notice that there is still some layer shifting occurring where the letters begin and end. The first and last layers also seem to have some additional shift. The last photo in that album shows the effect well.

I've tried using different temperature settings to see how that affects the first layer and the overall print smoothness, but those settings didn't seem to help remove the layer shifting.

-

That twist has nothing to do with calibration. One or more of your towers is not moving linearly. Are you by any chance using steel-cored belts?

-

I'm agree with David. I'm facing the same fate with the universe of delta printer. And I had twist issue too.

Before the different rods length (solved with changing all the system) and then geometrical issue (dismounting all the printer 3 times and measuring everything ).

The tree main towers were not exactly perpendicular to the bed and at the same distance between each other.

Now , I'm modifying the bed resistance for a better radial uniformity and the hot chamber for avoid delamination and warping.

EDIT: the TLL-90S is NOT a PRO TOOL , the description is substantially false. An other cheap attempt to steal money.

This week I'll receive this (PRO) tool for check all the geometries, TLL-90S (should be accurate enough ). The DXL360s should be good enough too. (i don't know if the DXL360 NON "s" is good enough)

But before to check as solved my old 3d I have to accomplish all the proper steps.

Unfortunately those issue happen for a reverse approach to the universe of 3D printing. We should've checked at first all this .

But , we didn't born already experienced.

This guide can help you :

https://forum.duet3d.com/assets/uploads/files/1550049854021-tlm-ultimate-calibration-tutorial-1.pdf

When it say double check , double check !!!

Those problems appear especially printing big parts. Printing small parts in the center of the bed can hide lots of mechanical imperfections. -

@dc42 I was never saying that the problem was CAUSED by the calibration. I was using the calibration as a debug tool to see if we can change the print behaviour.

Besides, how is the algorithm supposed to determine exactly the amount to rotate the towers? I find that the calibration is good at hinting at these major tower geometry problems, but it's best to sort them out manually rather than let the calibration "fix it."

-

@dc42 I do not believe I am using steel-cored belts. When you say the that one of my towers is not moving linearly, are you suggesting that there is some curvature to its movement?

In terms of its assembly, I measured the distance between each pair of towers at the top, middle, and bottom, and the horizontal distances were all identical to within 0.5 mm over height of the printer. So this leads me to believe that the towers are fairly parallel to each other. The angular offset should be no more than 0.05 degrees, if even that much.

I once again measured each of the diagonal rods and they were all close to 215 mm, but I measured them while the machine was assembled, so my confidence in them being exactly the same is reduced. That said, the rods (and towers) were cut and provided to me by Johann R, who designed the Mini Kossel, so I expect they were measured and cut precisely.

I want to note that I didn't have these problems with my RAMPS board, and nothing else about the printer has changed since the upgrade to the Duet 2 WiFi. Here's a sample print from when I still had the RAMPS board on: https://imgur.com/a/L1Hyo4S. I had also printed a 3DBenchy and it came out really nicely.

-

Would you be able to provide the settings you used for the delta parameters, steps per mm, etc. for the Ramps/marlin config?

-

The Marlin config is in my GitHub. A diff from the default settings is here: https://github.com/kjiwa/Marlin/commit/c0d4e67b1c7fc02f868063cb9aff10a0eb38b81c.

With the Marlin firmware I had the tower motors configured with the following values:

- max speed 500 mm/s

- max acceleration 9000 mm/s^2

- default acceleration 3000 mm/s^2

- default jerk 10 mm/s^3

Other than that, geometry and other settings are mostly unchanged between what I had set with the RAMPS board vs what I have set with the Duet.

-

@kjiwa It seems you were using auto calibration in marlin too.

Do you know what delta settings as a result of the auto calibration you were using that gave you acceptable results? Did you ever write them down?

-

Unfortunately I did not make a note of those values.

-

As "bot"(user

) , but with less skill , I try to give some help. I have lost so much time back this damn trap of a delta.

) , but with less skill , I try to give some help. I have lost so much time back this damn trap of a delta.

I'm agree with him about :I find that the calibration is good at hinting at these major tower geometry problems, but it's best to sort them out manually rather than let the calibration "fix it."

@kjiwa said in Delta printer twisting beginning of print:

@dc42 I do not believe I am using steel-cored belts. When you say the that one of my towers is not moving linearly, are you suggesting that there is some curvature to its movement?

In terms of its assembly, I measured the distance between each pair of towers at the top, middle, and bottom, and the horizontal distances were all identical to within 0.5 mm over height of the printer. So this leads me to believe that the towers are fairly parallel to each other. The angular offset should be no more than 0.05 degrees, if even that much.

I once again measured each of the diagonal rods and they were all close to 215 mm, but I measured them while the machine was assembled, so my confidence in them being exactly the same is reduced. That said, the rods (and towers) were cut and provided to me by Johann R, who designed the Mini Kossel, so I expect they were measured and cut precisely.

I want to note that I didn't have these problems with my RAMPS board, and nothing else about the printer has changed since the upgrade to the Duet 2 WiFi. Here's a sample print from when I still had the RAMPS board on: https://imgur.com/a/L1Hyo4S. I had also printed a 3DBenchy and it came out really nicely.

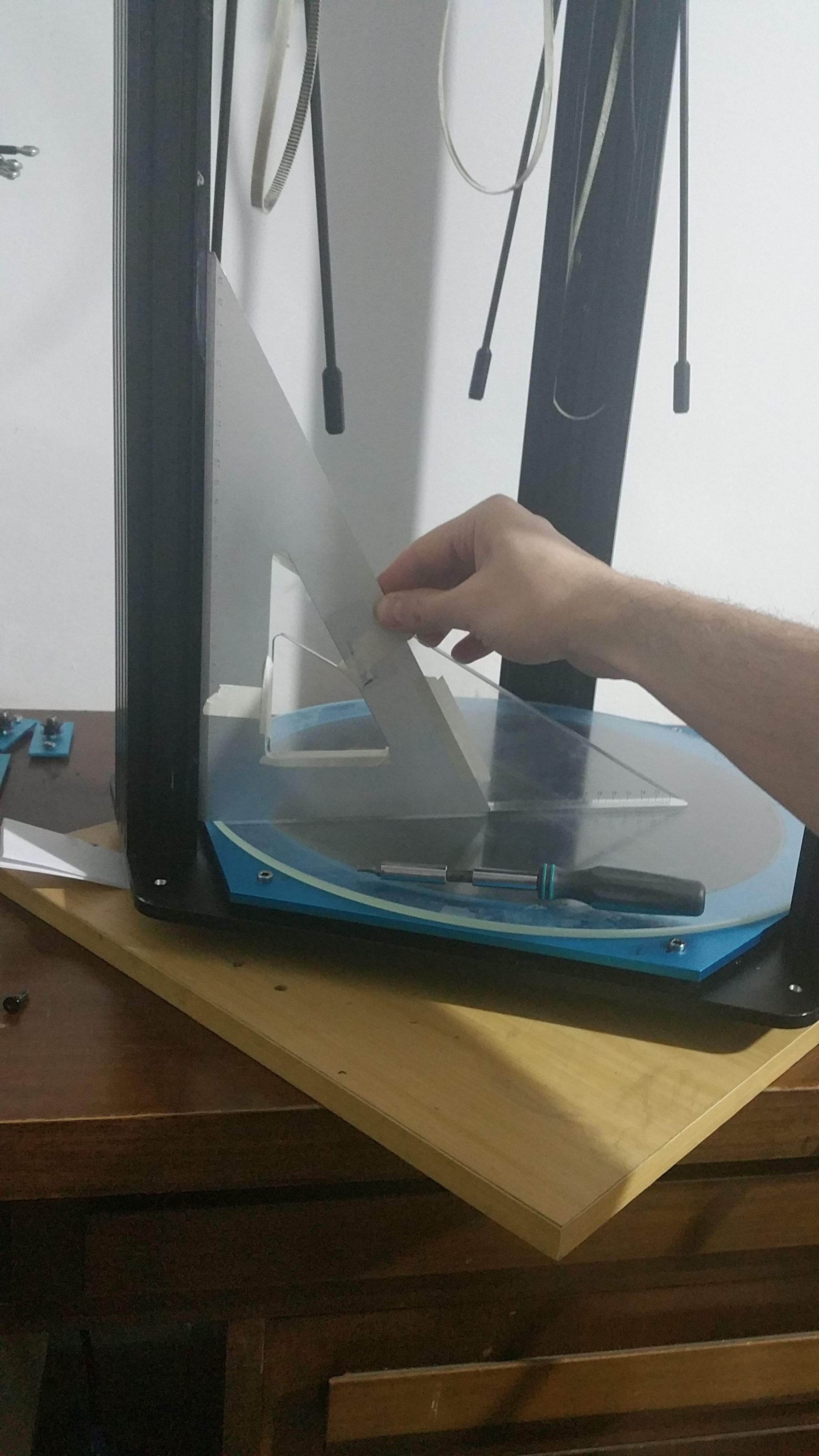

-The tower could have some torsion or be not perpendicular to the bed. If you put a drawing T-square against the bed and the tower , the two sides adhere perfectly? (I before blocked the two T-squares with bi-adhesive against an other square)

-I don't know how much difference are allowed in the towers geometries but for the rods must stay in the 0.1mm :

https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer

-Did you moved the printer? My delta is so heavy that if the bed is not flat to the ground the tower can flex a little.

-About the belts : the guy tested the GT2 and iron core saw that the last one elongation is 1/3 of the fiberglass core.

https://www.reddit.com/r/3Dprinting/comments/61j9et/i_tested_some_gt2_belts_to_failure_on_a_tensile/dffh799/

http://mark.rehorst.com/misc/corexy/dual belts Z 4kg.jpg

-I would give the full power at the motors in the config.g (1.5A).If you launch 10 strait calibration , how much big is the deviation between each others? If is too much must be a mechanical trouble. (just because the autocal found different results each time it was performed and it have to recalculate everything) If they are equal +/- 0.01x mm it look like the compensation is working. (ex could be better but is fair enough)

With a digital caliper the cube measure 5cmx5cm or is a rhomboid instead? By the pictures seems irregular.

If there is a mechanical issue the autocal can come even worse that leaving a low factor calibration in the bed.g.

You could try also S8 instead S4 but just avoid the factors that calculate the rods length. BUT you must be sure about the length of the rods!

(the only thing that the autocal make it wrong is calculate the rods length)

I designed a lower parallelepiped (30x3x2 cm) for check the real goodness of the autocal. In small and centered objects the calibration could seems good enough but if you print large object you will find really soon if some issue is still there.For my calibration.

-endstop all 3 at the same length on the carriage (measured with digital caliper).

-I put to zero the M666 in the override.g , save and reboot.

-I calculate the Z height and stored it in the M665 (override.g) , save and reboot and check if it is good (G1 Z0)

-I use the bed.g with 10 out point , 6 internal. The radius as much large you can till the rods are parallel to the towers reach the best results. X3 (tree pass at least). If the build is accurate the second an third pass should be more or less the same.

http://www.escher3d.com/pages/wizards/wizardbed.php

-Now if the geometries are good enough the autocal should work.

-You can refine with the mesh grid.The process is a chain, all the rings must be right.

Ah.... this print that look good enough (0.1mm height) is printed with a NOT well calibrated printer. But because in the middle of the bed, all the issue are less noticeable.

ps The ultra squished 1st layer depend on the glue that was irregular (I used a sponge)

Keep us aware of your new discovers

-

Thanks for the tips @giostark. But as discussed earlier, I'm fairly certain the rod length is accurate, and as I had mentioned, I was able to make good quality prints before when I was using the RAMPS board.

We're at a point where the twist is gone from my prints. It is a small print, but this indicates that my towers are likely straight, and not bowed or highly angled.

The issue I am seeing now is with layer shifting in the calibration cube where the letters begin and end. What could be causing that? There are entire sections of the print that are straight. It's only when there is a change in the object that the layers shift a little bit.

-

The angle that the firmware was adjusting for was the tower's placement around the circle. IE the Y tower was not evenly spaced compared to the other two.