Ender5pro, Duet2WiFi Slow by slicer

-

Guys,

Setting the Duet 2Wifi has being fun. Tons of experience and learning in the forums. I have made ll the mistakes in the book but made new friends correcting them.

Now that I am ready to print, Cura and Simplify are conspiring against the RepRap flavor

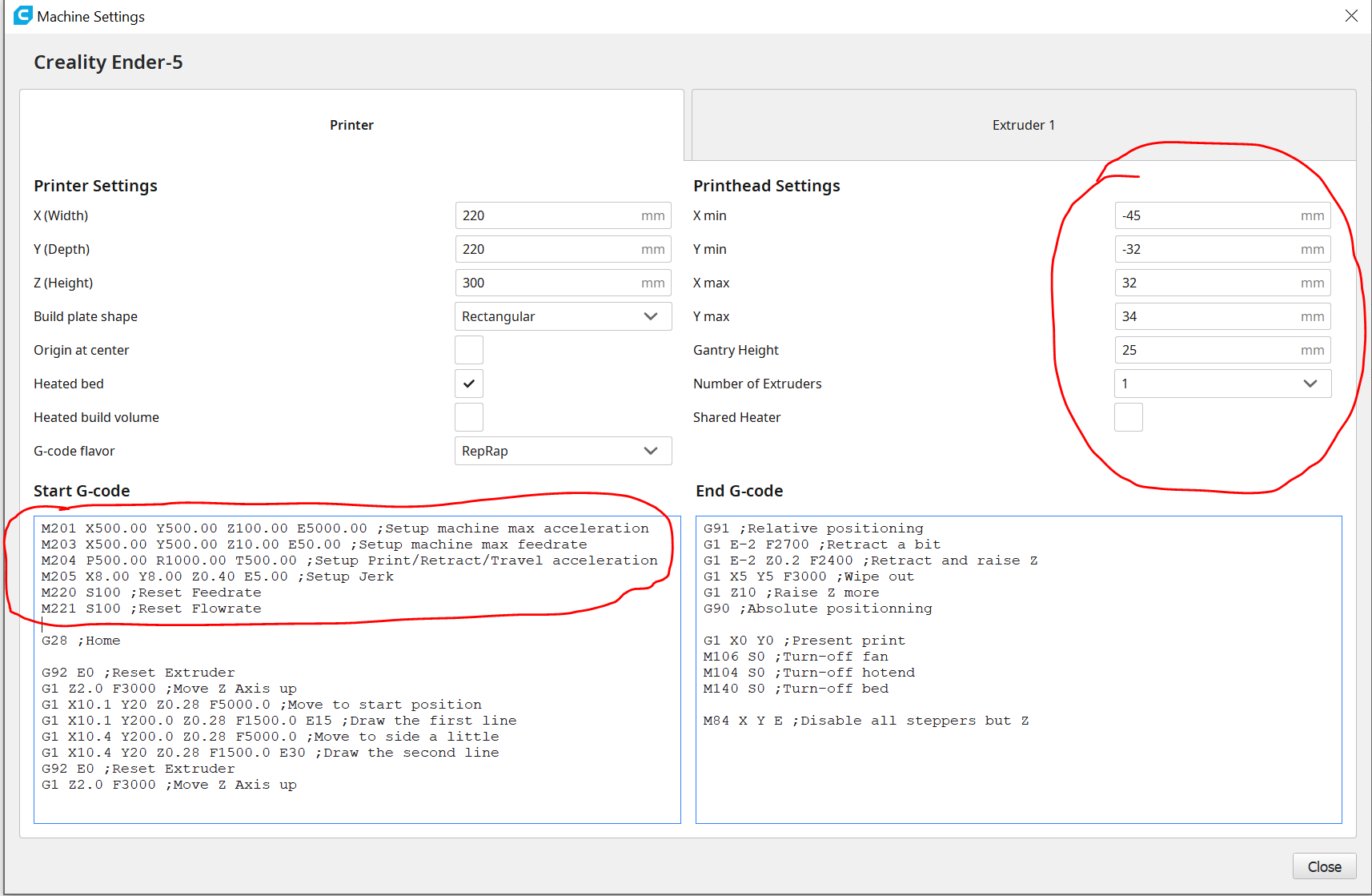

I am attaching below the Cura settings (4.06 version) for and Ender 5 RepRap

I am not sure about all this M201, 202, 203 204 205

On the right of the screen there is a series of offsets for the printing head, where are those used?

My config.g is just below...Thanks; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Apr 19 2020 17:01:43 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Daniel Ender 5 Duet 2 Wifi" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z779.00 E409.00 ; set steps per mm

M566 X900.00 Y900.00 Z24.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z900.00 E3600.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X850 Y850 Z850 E850 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X220 Y220 Z300 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-45 Y3 Z2.235 ; set Z probe trigger value, offset and trigger height

M557 X15:160 Y15:200 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 A88.4 C265.5 D2.0 S1.00 V23.9 B0 ; disable bang-bang mode for the bed heater and set PWM limit (Values copied from auto tune D corrected from 0.9 to 2 by Phaedrux)

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T98801 B4185 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M307 H1 A390.6 C153.8 D3.5 S1.00 V23.9 B0 ; disable bang-bang mode for heater and set PWM limit (Values copied from auto tune); Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 S"E3D V6 Nozzle X" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

The print head settings i THINK may come into play when doing one part at a time printing where it will print an entire part before moving onto the next (as opposed to printing a single layer of all the parts). It tells the slicer how big the print head is so it knows how far away to stay from the printed part. I'm not totally sure because I've never actually printed like that.

remove the M201, m203, m204, m205 commands. They were probably a part of the printer profile that was loaded. Not applicable to the Duet.

REsetting flow and feed rate can stay.

The G28 and stay. You can add G29 S1 if you want to load a heightmap.

The extruder bits are to prime the nozzle and can stay as well.

That should solve the speed problem.

-

@Phaedrux Thanks Phaedrux. I am flying now.