Hotend won't go above 177c

-

16.5 hours into a 17 hour print at 260c when the hotend plugged up.

Fixed that and now I get a heater error at 177c. Replaced thermister and heater cartridge twice. No change. Checked all wiring. OK and everything ohm's out correctly.

Ran PID and still errors at 177c. I increased the dead time to no avail.

Everything has been running fine until now.

Ver 1.23

Any help is appreciated. -

Any possibility of hot end fan, OR print fan, now being physically different where the air is going, as a side effect of that maint?

I know some of my toolchangers won't act right, won't get hot as they should, when parked, because air "bounces off" the various things in the parking stall. The do fine when out.

So airflow changes can make a huge difference.

-

@Danal No. Nothing has changed. I have done 60+ hour prints with this

setup. That is what is baffling me. Power at the hot end maintains 24v. -

What error does it give?

Can you post your config.g?

What does your heater graph look like?

-

If you dismantled the hot end, check that you have a gap between the top of the heater block and the bottom of the heatsink.

-

@Phaedrux Error: Heating fault on heater 1, temperature rising much more slowly than the expected 0.4°C/sec.

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Fri Mar 29 2019 23:01:22 GMT-0700 (Pacific Daylight Time); General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X330 Y300 Z375 S0 ; Set axis maxima; Endstops

M574 X1 Y1 Z1 S0 ; Define active low and unused endstops

M558 P5 X0 Y0 Z1 H5 F200 T6000 ; Set Z probe type to analog, the axes for which it is used and the probe + travel speeds

G31 X40 Y7 Z0.9 P50 ; Set Z probe trigger value, offset and trigger height;Z-offset (Z0.9). Higher value LOWER nozzle height ; Lower value RAISE nozzle heightM557 X10:340 Y10:240 S68 ; Define mesh grid

M564 S0 H0; Drives

M569 P0 S1 ; Drive 0 goes forwards - X

M569 P1 S1 ; Drive 1 goes backwards - Y

M569 P2 S0 ; Drive 2 goes backwards - Z

M569 P3 S1 ; Drive 3 goes forwards - ExtruderM350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation 16

M92 X160 Y800 Z1600 E90 ; Set steps per mm 16M566 X600 Y420 Z12 E120 ; Set maximum instantaneous speed changes (mm/min) - (JERK)

M203 X6000 Y6000 Z500 E400 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z200 E250 ; Set accelerations (mm/s^2)

M204 P1000 T1000 ; Set Max acceleration for P=printing moves and T=travel moves

M906 X1600 Y1600 Z900 E1000 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Heaters

M143 S285 ; Set maximum heater temperature to 285C

;M305 P1 X101M305 P1 T107000 B10832 C4.891620e-7 R4700 ; Set thermistor + ADC parameters for heater 0 - BED

M305 P0 T99600 B4388 C0 R4700 ; Set thermistor + ADC parameters for heater 1 - HOTEND E3dM307 H0 P96.0, I3.285, D603.9 ;Bed

;M307 H1 P1.1, I0.011, D51.5 ;Hotend pidM307 H1 P17.8, I0.055, D74.9 ;Hotend E3d pid

; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Network

M550 P"Black Widow" ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned onM501

; Automatic saving after power loss is not enabled

; Custom settings are not configured!

-

@tinfish340 said in Hotend won't go above 177c:

M305 P1 T107000 B10832 C4.891620e-7 R4700 ; Set thermistor + ADC parameters for heater 0 - BED

M305 P0 T99600 B4388 C0 R4700 ; Set thermistor + ADC parameters for heater 1 - HOTEND E3dIt looks like you have P1 and P0 flipped.

-

Changed that around and ran PID auto tune and that fixed it.

Thanks for your help!!! -

So apparently that did not fix the problem. It did go up to 270C with no problems but upon printing there was almost no bonding between layers. The whole print just came apart. I feel like the problem lies within the board. How do you go from a perfectly good printer to junk when absolutely nothing changed as far as code goes? It will struggle to reach 210C now with no errors no matter how long it takes to get there.

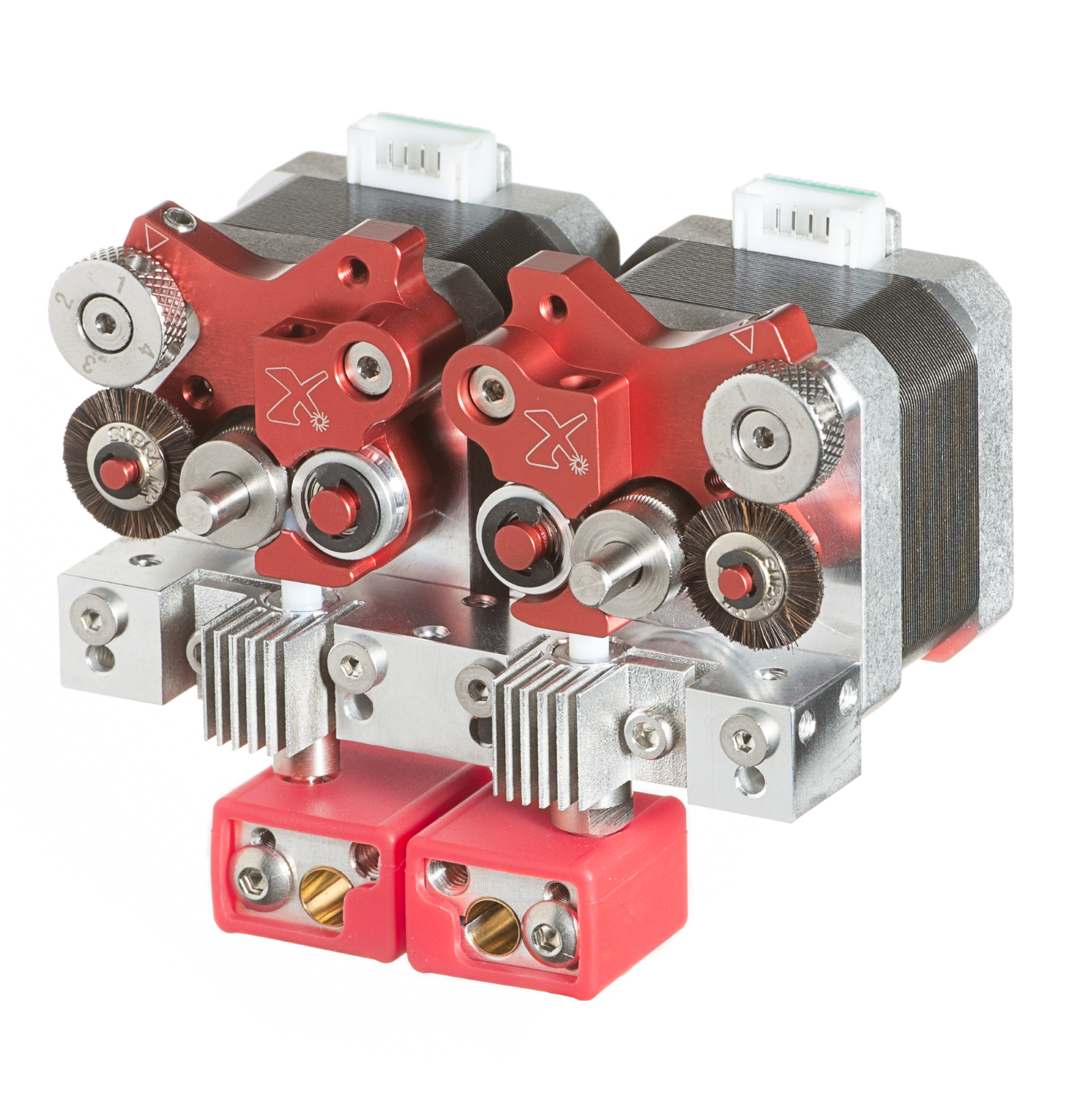

FYI, I am using this. Flexion Dual Extruder

-

Where did you get the thermistor values?

M305 P1 T107000 B10832 C4.891620e-7 R4700 ; Set thermistor + ADC parameters for heater 0 - BED M305 P0 T99600 B4388 C0 R4700 ; Set thermistor + ADC parameters for heater 1 - HOTEND E3dIf they are wrong, the displayed temp will not match the actual temp.

-

This printer is a highly modified Black Widow that I have been using for years. Not much Black Widow left but these are the original settings. These settings have worked for a very long time until now. I also came up with the same settings when using the configurator. But I am open to anything that will get this working again.

-

Well what kind of thermistors are they?

This is a Duet Wifi with firmware 1.23?

-

Gulfcoast Robotics 100K NTC 3950 - M3 Stud Screw-in thermistor and

I have also tried, not sure of the brand, NTC 3950 100K Thermistor with the glass end.Duet WiFi Server Version: 1.23

-

Have you tried the values for NTC3950 100k thermistor?

You can also try deriving the values like so: https://www.jameco.com/Jameco/workshop/techtip/temperature-measurement-ntc-thermistors.html