[solved] FAN tool - vibration - bump white led (smart effector)

-

-

I suggest you renumber the fans so that fan 0 is the print cooling fan and fan 1 is the thermostatic heatsink fan. This is because fan commands generated by the slicer go to fan 0 by default.

-

In the M106 commands that configure thermostatic fans, use S1 not S0. The S parameter is the speed to run the fan at when the thermostatic control is triggered, but if you specify less than S0.5 then S0.5 will be used.

-

-

Thanks DC! I'll do that

-

Still here,

I bought those fan Gelid 5 (x2):

https://www.amazon.it/gp/product/B008S1DN66/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

I have to say that they produce far less vibration of the Foxcon 50mmX10mm despite those are 50mmX15mm and they are even more silent.

But I can't understand why I can't regulate the power with the X parameter.; Fans M950 F0 C"fan1" T1 ; part fan M106 P0 S0 H-1 ; M106 P1 S0 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off M950 F1 C"fan0" T0 ; tool fan M106 P1 S1 X1 H1 T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on at 45degree - 0.3 is 30% M950 F2 C"fan2" T2 M106 P2 S0 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off - 0.3 is 30% ;M106 P2 S0 I0 F500 H0 T50 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on - ho unito le ventole quindi questo non serveIf I enable the X value as any number under 1 (0.9 , 0.8 etc) the fan didn't start and just pulse in the attempt to start to spin. As the pulse, the white leds of the smart effector also blink at the same time of the pulse.

Those are the spec:

- Silent Operation

- Optimized Fan Blades

- High Airflow & High Static Pressure

- Long Lifetime (50'000 h MTTF at 40°C)

Other Characteristics:

Cable length: 0.45 m

Depth: 50 mm

Fan connector: 3-pin

Fan diameter: 5 cm

Height: 15 mm

Maximum air pressure: 2.8 mmH2O

Maximum airflow: 12.9 cfm

Noise level (high speed): 23 dB

Rated current: 0.15 A

RoHS compliance: Y

Rotational speed (max): 4000 RPM

Suitable for: Computer case

Type: Fan

Voltage: 12

Weight: 30 g

Width: 50 mm

Now, the board is capable to make the fan spin at full speed with and without the thermostatic value ON. But with the X less than 1 it pulse.

Both the fan are new and not garbage. -

Are you able to adjust the speed with S.08? Some fans just don't like being PWMd. Try a different frequency with F.

-

With the base of this M950 I tried this permutation of M106:

M950 F1 C"fan0" T0 ; tool fanM106 P1 S0.8 X1 H1 ; (tried also with T45) didn't spin at all.

M106 P1 S1 X0.8 H1 ; (tried also with T45) didn't spin at all.

M106 P1 S0.8 X0.8 H1 ; (tried also with T45) didn't spin at all.

M106 P1 S1 X1 T45 ; this is the only one that seems to work and make spin the fan without issue at full regime.

Also tried to add F466 (def frequency) or F200 but didn't change a thing in any condition. -

For testing use H-1 to disable thermostatic control. With H1 you are tying it to the extruder and you'll need to specify a temp with T for the fan to spin up.

You can also add a B value for full power blip time since some fans need full power at startup to overcome resting state.

-

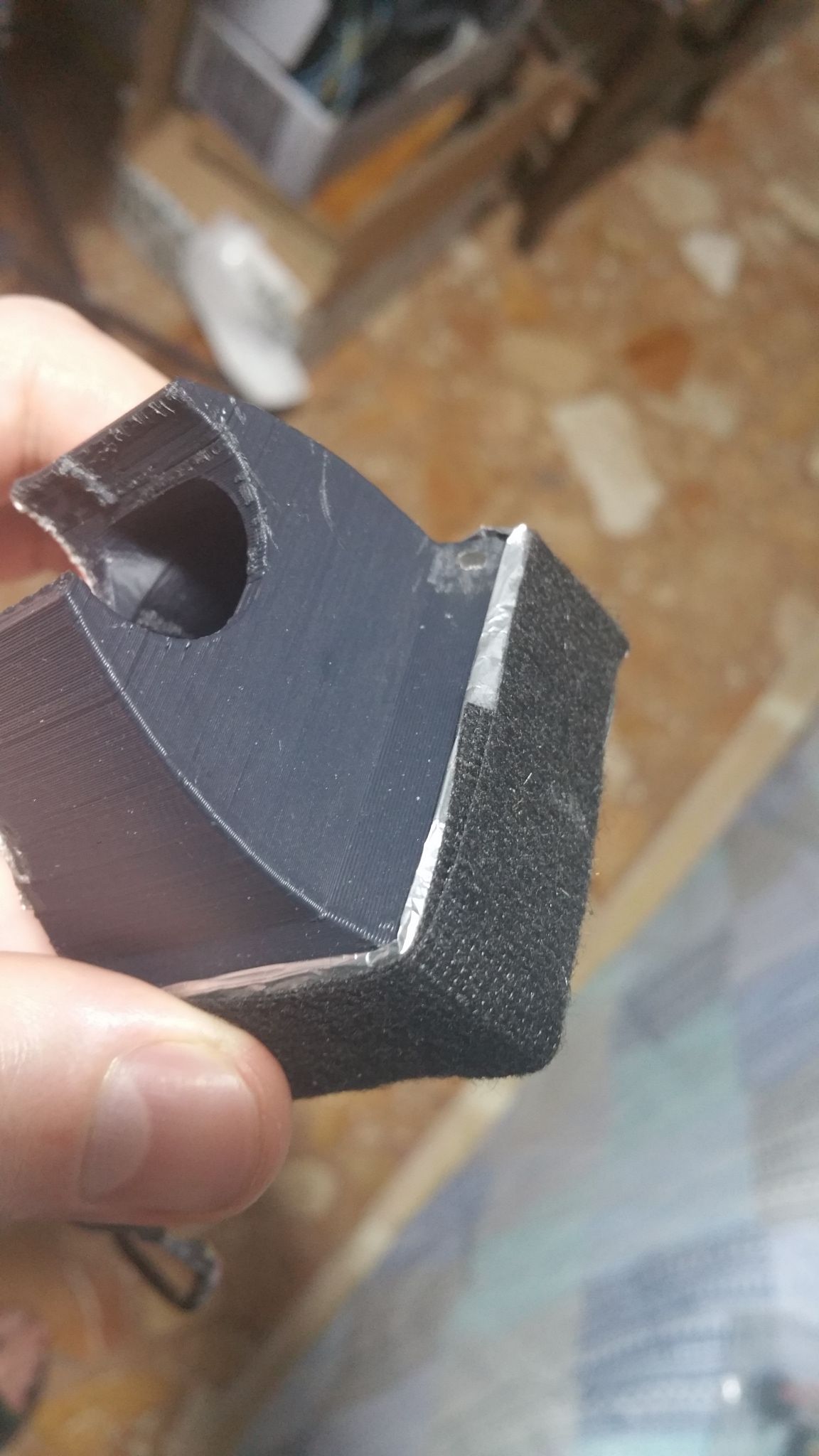

Ok , I'll try that soon as have finished to redesign the conduct.

I tried the the Noctua NA-RC10 resistor and it in thermostatic mode became ultra silent, BUT lose too much flow.

At first I thought that lowering the flow could avoid the turbulence close the bed , but I sorted out that I have to redesign the fan conduct and keep it at least 2cm more hight for solve completely the issue.

Soon as I'll have finished it I'll post it here with full files on Thingiverse. Will be a good add-on for the Smarteffector.

I'm adopting an asymmetric blades conduct for guide the flow. the prototype already work well but I want make a better revision.

Thanks Phaedrux for your time. You keep always answering

-

Ok,

I found the culprit. Electromagnetic fields.

I designed a new duct for the fan and everything worked fine , then I re-designed the duct for a more efficient flow and the fan now stay 5mm closer to the effector than before and tadaaaa , still this fan didn't want start. Same behavior.

Some blink trying to spin and nothing else.

So I took a common aluminium sheet (the cooking one) and bent on itself and finally placed on the perimeter of the fan and magically now it start to spin regular.

-

I'm glad you solved it!

Have you made sure that the ends of the magnetic rods have alternate N and S poles going around the effector? If they are all N or all S then the magnetic fields are less well contained and affect fans more often.

-

@dc42

I didn't even know I had to check this ... ok I'll have a look at it. Thanks as always for sharing knowledge

I didn't even know I had to check this ... ok I'll have a look at it. Thanks as always for sharing knowledge

Edit: yep of course I had all N and S placed But it was easy alternate looking the stickers!

But it was easy alternate looking the stickers!