Blower issue

-

I have same bondtech extruder on my hevo and my mk3s from bondtech. I use same blower from prysa on booth machines. The prusa machine has way better cooling then the one on the duet card. How can i fix this? Changing my PWM value have no affect. tried f

25/250/2500/25000 made no difference what so ever. -

Do the two machines have different fan ducting?

-

This post is deleted! -

@dc42 said in Blower issue:

Do the two machines have different fan ducting?

No same extruder completely. Booth are bondtech sls printed mk3s housings. Only difference are longer cables on the hevo and its a duet card. Also should it not change anything when playing around with the f value?

-

@Alucardi You haven't said what board you are using but do you have fan voltage set correctly? Are you running a 12V fan with 5V? Or a 24V fan with 12V?

-

@deckingman i use a duet wifi card. its 5v on the prusa original blower fan. Thing is f value have no affect on my hotend fan either. it is like f value means nothing. I has in the past. But now changing the f value makes no difference.

I bought the machine with configured firmware and according to previous owner he did sett the fans using f values. But i cant seem to get any difference. So was he just bullshitting me? Sounds unlikely cause he still talks to me. The fans are just 3 pin fans so i guess that is why PWM dont work right? -

@Alucardi It's possible that I might be because they are 3 wire fans but it depends on a lot of things. The PWM frequency doesn't necessarily have anything to do with fan speed. It's not the same as the PWM percentage which is the on-off ratio. The frequency just sets how quickly the on-off cycle changes. 50% PWM would be on for half the time and off for half the time. The frequency determines the time interval. For example at a frequency of 10 Hz, in one second there would be 10 on/off cycles lasting 1/10 th second each. So the fan would be on for 5 x 1/10th second = 0.5 seconds. With a frequency of 100 Hz, the fan would be on for 50 x 100th second = the same 0.5 seconds.

So you might be confusing PWM frequency with PWM percentage. Suggest you post your config.g file so that we can see if we can spot anything.

-

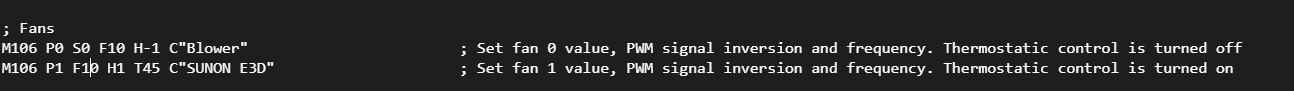

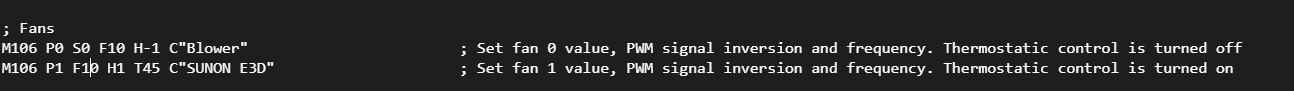

@deckingman I am just wondering why he said he spent a lot of time tuning the frequency of the fan when its actually not doing anything. here is a print screen of my fan config. Is there a override config like the one you can have for the PiD tuning?

-

@Alucardi said in Blower issue:

@deckingman I am just wondering why he said he spent a lot of time tuning the frequency of the fan when its actually not doing anything. here is a print screen of my fan config. Is there a override config like the one you can have for the PiD tuning?

I can't answer why that person said whatever it was he said - you'll have to ask him that question.

The contents of config_override will do just that - override anything that is in config.g. So if there are fan control commands in config_override.g then yes, they will override whatever settings you have in config.g.

I've tried to explain the difference between PWM value and PWM frequency. I would not expect changing the frequency to alter the fan speed. Some fans play nicely with PWM, some do not. Sometimes using a different PWM frequency can help to make fans play nicely. But if the fan is spinning and responds to changes in the PWM value, then changing the PWM frequency is unlikely to make any difference.

For non-thermostatic fans such as part cooling fans, you can change the PWM value by using M106 Snn or you can use the slider on the web interface. Does using this slider make the fan speed ramp up and down? If you set the slider to maximum, then send M106 P1, when value does it report back?

-

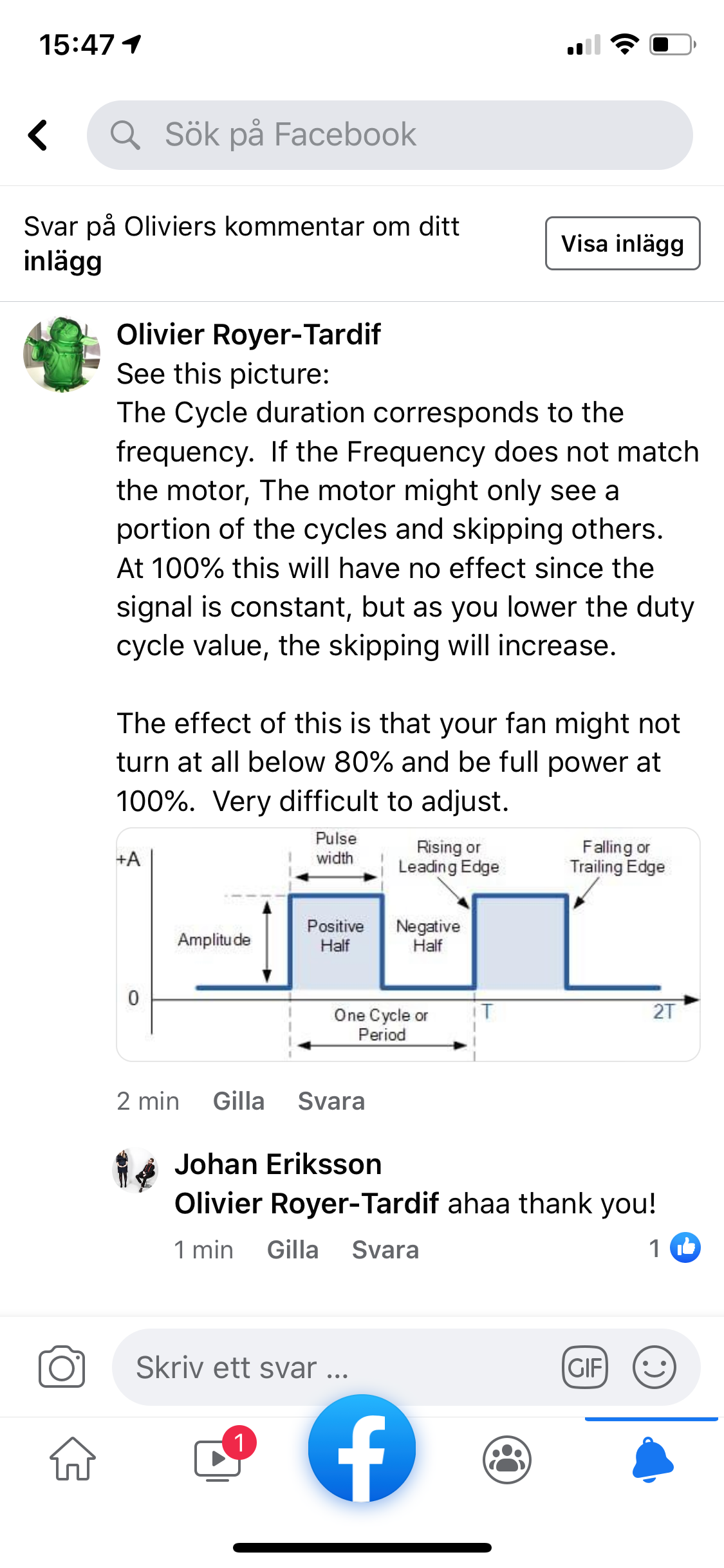

@deckingman I got a great answer facebook and now I understand how to use value and what it is for.

-

@Alucardi Sometimes a picture works better than words - especially if those words are not in your native language. Glad you now understand.