Need help to config file for ender 3 pro

-

Try lowering the acceleration and jerk for the Y axis. Perhaps the big heavy mirror is making it shake on direction changes.

-

@Phaedrux yaaaaaaaa I fix it thnks for your help. My hotend and cooling part fan was Vibrates slightly

It's due to their frequency settings.

I couldn't find a frequency that would make them stop vibrating.

So I returned to ender 3 stock fun and changed frequency now Hard to see ringing Thank you so much for your time and for your help.

And everyone who helped

,

You think I should change my config like before? -

@Roei3d said in Need help to config file for ender 3 pro:

You think I should change my config like before?

Well you can try increasing your speed values as part of your tuning.

Maybe see here: https://forum.duet3d.com/topic/14250/tuning-jerk-accel-speed-settings/3

-

@Phaedrux thnks my last print look very good thnks for your help

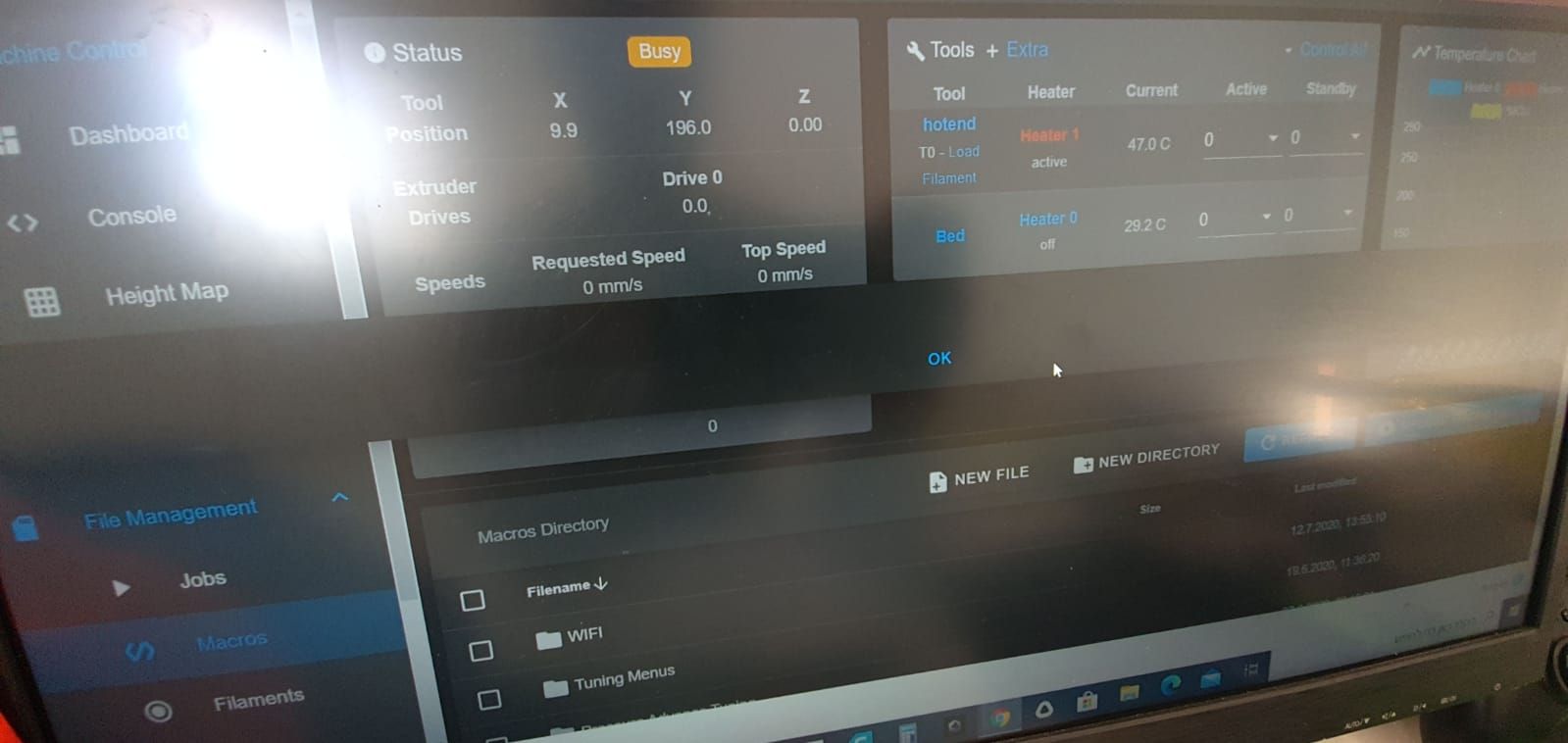

ihave problem whit my duet web when irun macro iget blank status i see only "ok"

only "ok"

if change to dwc1 isee all' how to fix it ? -

@Roei3d Are you running Firmware 3.1.1 and DWC 3.1.1 now? If you're still running firmware 2.x you either need to upgrade to 3.1.1 or change your DWC version to something like 2.0.7 that came with firmware 2.05.1

-

@Phaedrux yes iam ruining

RepRapFirmware for Duet 2 WiFi/Ethernet version 2.05.1 running on Duet WiFi 1.02 or later

so ineed to upgrade my firmware to 3 ?

or downgrade swc to 2.0.7?

-

Yes. First I would try just uploading the 2.0.7 DWC zip file and see if you still have the problem. Updating to RRF3 is a bit more involved and would require updated config.g. By contract, changing the DWC version is as easy as uploading the version you want to try.

https://github.com/Duet3D/RepRapFirmware/releases/download/2.05.1/DuetWebControl-SD-2.0.7.zip

-

@Phaedrux great thanks i try now

-

@Roei3d Hello! Are you using the stock fans? What are the frequency values that you are using now? Could you please share your current config.g? Thanks!

-

@bettodiaz hii yes now ihave tock fun only the board fun i change

this my config

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X79 Y79 Z396 E408 ; set steps per mm

M566 X1000 Y1000 Z24 E2500 P1 ; set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z900 E6000 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X688 Y688 Z688 E810 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X235 Y235 Z240 S0 ; set axis maxima; Endstops

M574 X1 Y1 S1 ; set active high endstops

M574 Z1 S2 ; set endstops controlled by probe; Filament runout sensor ;Filament run-out sensor triggers a pause

M591 D0 P2 C3 S1; Z-Probe

M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P9 H2.5 F350 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-40 Y-12 Z9.562 ; set Z probe trigger value, offset and trigger height

M557 X30:220 Y30:220 S40 ; define mesh grid; Heaters

M305 P0 T98801 B4185 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S100 ; Set temperature limit for heater 0 to 120C

M305 P1 T98801 B4185 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S250 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0 I0 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0.8 I0 F20 H1:0 T45 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 S"hotend" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Pressure Advance

M572 D0 S0.35; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0 ; Select first tool; BLTouch startup

G4 S2 ; Pause a couple seconds

M280 P64 S160 ; Clear any alarms

G4 S2 ; Pause a couple seconds

M402 ; retract pin just in case; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@Phaedrux you are the king of duet work great thnks