Pause the print for the day.

-

@CarlBosson See https://duet3d.dozuki.com/Wiki/Installing_and_Updating_Firmware#Section_Usual_procedure

Use files from https://github.com/Duet3D/RepRapFirmware/releases/tag/2.05.1

You will probably also want to update DWC and possibly your WiFi firmware. See https://duet3d.dozuki.com/Wiki/Installing_and_Updating_Firmware#Section_Updating_WiFi_firmware_or_DuetWebControl_files

Ian

-

Thank you all of you for your help so far!

I updated firmware only for now and all seems to be running well. I will conduct the first pause and power down test within the hour and if that goes well then a complete cold shutdown over night tonight and restart test. I will keep you updated. Again thanks!

Carl

-

The first test was a success! Thanks for all the help! After the firmware update there was no excessive extrusion at restart after power loss.

Today I will start a test print about an hour before we go home for the day. I will pause and power down like this morning, but I will not restart until tomorrow morning 7am EST. The printer will be at room temp when I get to work 75 deg F, this will test bed adhesion.

-

@wieman01 Of course you were correct the print did come loose. But I am not finished

We have bead basted a glass build plate and also using Nano polymer. I will power down tonight and see what we get in the morning.

We have bead basted a glass build plate and also using Nano polymer. I will power down tonight and see what we get in the morning.

-

@CarlBosson Haha... Look forward to the results. You will figure it out, I am sure. But warping is quite a beast that you have to tame.

-

Maybe a standby heater to keep it warm?

-

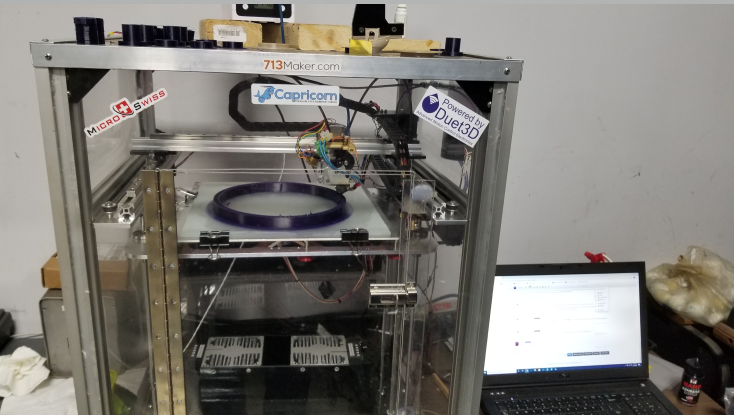

Here is the printer with part still on the build bed this morning!

-

The part made it the first night! But this is a 40 hour print so I will have to cool and heat this part four times! The question is not will it stay overnight. The question is will it stay overnight four times!

-

If that's brim at the bottom, maybe you can glue down the edges with PVA adhesive?

-

@dc42 Yes, that is a brim.

-

The print has failed do to a stepper issue. Stopped extruding. This print was stuck to the bed well. Once i fix this stepper issue I will restart. Thank you everyone for your help and input.

-

@CarlBosson said in Pause the print for the day.:

The print has failed do to a stepper issue. Stopped extruding. This print was stuck to the bed well. Once i fix this stepper issue I will restart. Thank you everyone for your help and input.

Ah, shoot, that is too bad. I was looking forward to the final print. I am amazed it really stuck to the plate, so really good job there!

I hope the adjacent layers look all right after the pause when you resume the print.

-

@wieman01 I don't have a photo but there was only a very fine line. So you could see where it stopped and then restarted. I mean to say that I could see it only because i knew it was there.

-

@wieman01 I am back up and running. I need to finish this print so I am going to run through the night without stopping. Once I have the part I need I will restart the trial print. Stopping over night and restarting in the morning. This will most likely be early next week. I will send pictures.

-

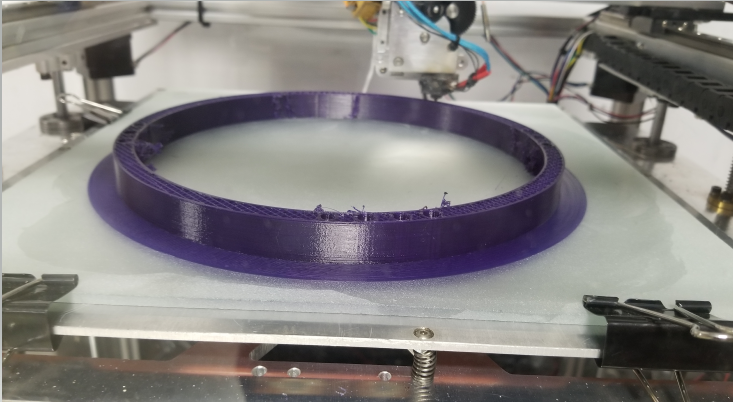

Ok here is the update. The test was a success! If you do not mind losing a mirror

. After I got back up and running, I also changed filament, I changed to 3Dxtech CarbonX

. After I got back up and running, I also changed filament, I changed to 3Dxtech CarbonX NYLON PA6+CF. This filament prints very well by the way.

NYLON PA6+CF. This filament prints very well by the way.So, to recap, I used standard 12" X 12" mirror tiles from Home Depot. I particle blasted the mirror to get it some texture then added two layers of Nano Polymer Adhesive letting it dry between layers. I did not use a brim this time with the added texture from blasting the glass it was not nessary. Enclosure temp was around 82⁰C Extruder 275⁰C Bed was 110⁰C. I started to print last Thursday and printed thru the night until Friday then shut everything down around 10:30am with about four hours left to go in the print. I came back in on Monday morning and restarted the print it finished without to may problems.

First issue there is a small visible line where the print restarted but I could clean this up if I wanted. This restart line did not affect the strength of the part at all. I dare you to try to break this part! Next, The part was stuck to the mirror so well that it broke trying to remove the print. It also left small pieces of glass stuck to the bottom of the print. I removed these with a small die grinder and proper PPE of course.

You can see the re start line at around 62mm in the photo.

This is the finished part.I think I will keep trying but will cut back on the adhesive. Thanks for all your help and have a great day.