What should be my first calibration steps on a new build?

-

Post your config.g just in case there is something odd there.

What slicer are you using ?

Did you configure your slicer for RRF (Rep Rap Firmware) ? If you have configured the slicer for the wrong firmware, all kinds of odd things start happening.

BTW, you shouldn't have seen a reasonable cube test print either. -

My nozzle is a .4, so again learning I'm thinking I could have a .4 wall. Maybe that's unrealistic. I have a duet3d board and use the configurator to put it together. I'm using cura 4.4.1

I can post my config if that helps.

-

@jens55 said in What should be my first calibration steps on a new build?:

@fcwilt said in What should be my first calibration steps on a new build?:

Hi,

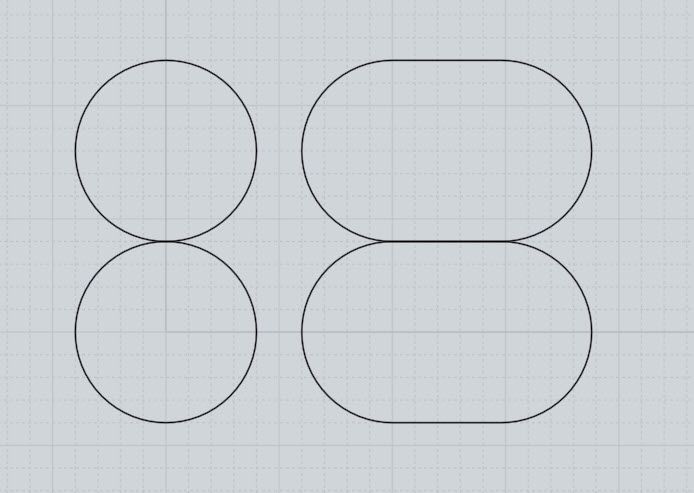

Consider the idealized images below.

The two circles on the left represent using line width that matches the nozzle size.

The two ovals on the right represent using a line width that is greater than the nozzle size.

As you can see you get much more contact between layers with a oval shape.

More contact will normally yield a stronger print.

This is misleading as you play down layer height. If you have a 0.4 mm nozzle and a 0.2 mm layer height you will never get the round shape on the left of your picture.

That's why I qualified it and did not specify a layer height of 0.2.

It was simply to point out the importance of good contact between layers, which under extrusion may prevent.

Frederick

-

You can have a 0.4 mm wall although there is an argument to be made to set your wall line to 0.5 mm (I use 0.4mm line width if I use a 0.4 mm nozzle).

Yes, post your config.g

Have you measured the layer height of your first layer (the one you say is 0.8 mm wide?) -

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

You might get something out of this as a starter.

And then maybe this: https://forum.duet3d.com/post/130939

-

Height is .3

Config

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Fri May 24 2019 20:44:40 GMT-0500 (Central Daylight Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Network

M550 P"3DPrinter" ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Physical drive 0 goes Backwards

M569 P1 S0 ; Physical drive 1 goes Backwards

M569 P2 S1 ; Physical drive 2 goes forwards

M569 P3 S0 ; Physical drive 3 goes forwards;current settings

M584 X0 Y1 Z2:4 E3; two Z motors connected to driver outputs Z and E1

M671 X-81.5:291.5 Y110:110 S2 ; leadscrews at left (connected to Z) and right (connected to E1) of X axisM350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X99.9 Y100.1 Z399.6183 E99. ; Set steps per mm

M566 X900.00 Y900.00 Z12.00 E110.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z4000.00 E1200.00 ; Set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; Set accelerations (mm/s^2)

M906 X1100.00 Y1100.00 Z1100.00 E1100.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits old

;M208 X20 Y0 Z0 S1 ; Set axis minima

;M208 X230 Y210 Z200 S0 ; Set axis maxima;New Settings

M208 X-20:230 Y-20:230 ; X carriage moves from 0 to 210, Y bed goes from 0 to 210; Endstops

M574 X1 Y1 S1 ; Set active high endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

; new suggested settings

M558 P9 H5 F120 T6000 A5 T0.0 ; Set Z probe type to bltouch and the dive height + speeds (F100 T2000 original settings)

;M558 P9 H10 F500 T4000 X0 Y0 Z1 ; Set Z probe type to bltouch and the dive height + speeds (F100 T2000 original settings)

G31 P25 X34.82 Y-8 Z-.033 ; Set Z probe trigger value, offset and trigger height

M557 X0:210 Y15:210 S52.5 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

M501 ; Load saved parameters from non-volatile memorybed

;Suggested settings from the Duete3D Dozuki.com

G28 ; home

;M401 ; deploy Z probe (omit if using bltouch)

G30 P0 X35 Y105 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X205 Y105 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

;M402 ; retract probe (omit if using bltouch) -

I can't see anything obviously wrong here that would account for your issues.

Are you saying that your first layer is 0.3mm high and 0.8 mm wide ?

What are your slicer settings for first line width and height ? -

That's correct

Layer H .2

Initial Layer H .3

Line Width .4

Wall line .8

Outer .8

Inner .8

Top / Bottom .4

Infill .4

Initiall layer line width 100%Wall line count 1

Top bottom thickness .8

Top layer 2

Bottom layers 2

Enable ironing checked

Infill Desity 40

Infil line distance 1mm

Temp 205

Plate 70

Ratraction Distance 2

Retraction speed 25mm/s

Print speed 40

Enable accelration control checked

Enable jerk control checked -

I am out of ideas, sorry ....

One thing though .... you say you measured line width at 0.8 mm ... was that measuring a SINGLE line or did you measure wall thickness (which is two lines and should be 0.8 mm)? -

Single line