Duet 3 chamber heater setup issue

-

I am trying to get my chamber heater working on my Duet 3. I am using an SSR and if I provide the SSR with voltage it triggers and the heater works. When I try to activate it with DWC, it just faults because there is no change in temp and I get the rising too slowly error.

Here is the relevant section of my config file on the chamber heater:

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out3" T3 ; create bed heater output on out0 and map it to sensor 3

M141 H3 ; Define heater h3 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150CI am using Duet Web Control 3.1.1. Note the temp is correct and reflects change if you manually cycle the ssr.

Any suggestions would be appreciated.

Thanks,

Mark

-

Have you tried to PID tune the heater yet? If you can get it to tune it will have a model of its performance and won't error anymore.

Chambers are tricky though because they heat so slowly, it's difficult to know if it's actually heating or if there is a fault.

Where is your thermistor located? The closer the sensor is to the heater the tighter the control loop.

If it can't auto tune, you can derive your own PID values.

Have you seen these?

https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_a_chamber_heater

https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control

-

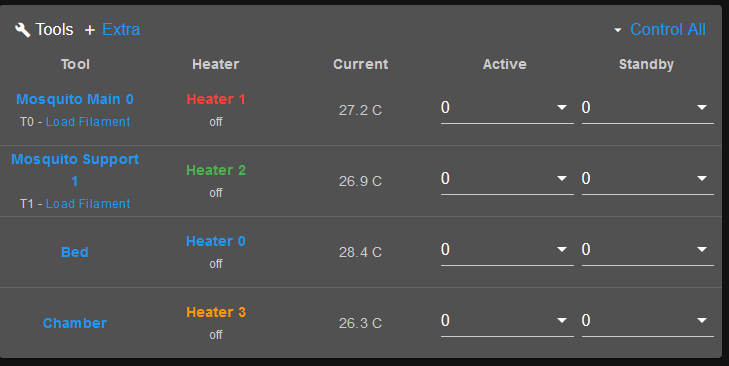

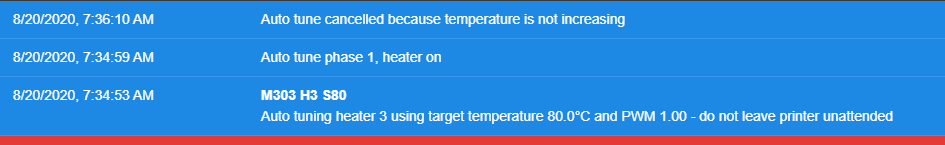

I tried to tune as you suggested:

The SSR has an LED that lights when it is activated and it didn't turn on during tuning. It will activate if I supply voltage to the terminals so I verified it works.

-

Post your full config please.

Also what wires go where on your duet 3? Post a photo?

-

Try using M307 to increase the dead time parameter to 60 seconds before tuning.

-

I switched from out3 to out7 and mapped it per config file below and it works. I am not sure why but at least the chamber heater works now and I was able to tune it.

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X600.00 Y600.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X120000.00 Y120000.00 Z1200.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X800.00 Y800.00 Z30.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z3200 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.722 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 170C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; set temperature limit for heater 1 to 450C

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S450 ; set temperature limit for heater 2 to 450C

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out7" T3 ; create bed heater output on out7 and map it to sensor 3

M141 H3 ; Define heater h7 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C; Fans

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config overrideM572 D0 S0.7 ; enable pressure advance