Thank you very much for your help. I changed the M84 in the config.g file to 20 and all is well. Please mark this resolved and again, a big thanks for the quick response.

Mark

Thank you very much for your help. I changed the M84 in the config.g file to 20 and all is well. Please mark this resolved and again, a big thanks for the quick response.

Mark

Sorry about the bad link. Here is the correct link for the video:

https://vimeo.com/456388566

config file:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X9000.00 Y9000.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z500.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X9000.00 Y9000.00 Z50.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X2200 Y2200 Z3200 E1800:1800 I0 ; set motor currents (mA) and motor idle factor in per cent

M84 S.5 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.59 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 170C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; set temperature limit for heater 1 to 450C

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S450 ; set temperature limit for heater 2 to 450C

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out9" T3 ; create bed heater output on out9 and map it to sensor 3

M141 H3 ; Define heater h3 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C

; Fans

;M950 F0 C"out8" ; create fan 0 on pin out8 and set its frequency

;M106 P0 C"fan + lights" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

;M563 P0 D0 H0 ; tool 0 uses extruder 0, heater 1 (and fan 0)

;M563 P1 D1 H1 ; tool 0 uses extruder 0, heater 1 (and fan 0)

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config override

M572 D0 S0.4 ; enable pressure advance

M572 D1 S0.4 ; enable pressure advance

Hello everyone,

I have been printing with my Duet 3 powered corexy for a couple of weeks and now I am having a "loop" where when I try to home, it resets to an unhomed state upon homing. If you do a single axis it does the same thing and flashes homed and then resets to unhomed. No errors on the console reported.

Short video of the homing issue:

https://vimeo.com/manage/456388566/general

Here is the M122:

9/9/2020, 6:07:29 PM m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v0.6 or 1.0 (SBC mode)

Board ID: 08DJM-956L2-G43S4-6J9F2-3SJ6M-1A6UG

Used output buffers: 1 of 40 (13 max)

=== RTOS ===

Static ram: 154604

Dynamic ram: 163388 of which 20 recycled

Exception stack ram used: 528

Never used ram: 74676

Tasks: NETWORK(ready,1968) HEAT(blocked,1188) CanReceiv(suspended,3820) CanSender(suspended,1384) CanClock(blocked,1436) TMC(blocked,60) MAIN(running,4544) IDLE(ready,76)

Owned mutexes:

=== Platform ===

Last reset 00:42:06 ago, cause: software

Last software reset at 2020-09-10 01:25, reason: User, spinning module LinuxInterface, available RAM 74788 bytes (slot 2)

Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN

Error status: 0

MCU temperature: min 40.2, current 40.3, max 40.5

Supply voltage: min 23.8, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0

Driver 0: standstill, reads 40080, writes 4 timeouts 0, SG min/max 0/638

Driver 1: standstill, reads 40080, writes 4 timeouts 0, SG min/max 0/646

Driver 2: standstill, reads 40080, writes 4 timeouts 0, SG min/max 0/861

Driver 3: standstill, reads 40083, writes 0 timeouts 0, SG min/max not available

Driver 4: standstill, reads 40084, writes 0 timeouts 0, SG min/max not available

Driver 5: standstill, reads 40083, writes 0 timeouts 0, SG min/max not available

Date/time: 2020-09-10 02:07:26

Slowest loop: 5.28ms; fastest: 0.14ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 375, MinFreeDm: 373, MaxWait: 49201ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 90, completed moves: 90, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 3 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is ready with "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 1.97ms; fastest: 0.01ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 0 of 8

Any suggestions would be appreciated.

Mark

I switched from out3 to out7 and mapped it per config file below and it works. I am not sure why but at least the chamber heater works now and I was able to tune it.

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X600.00 Y600.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X120000.00 Y120000.00 Z1200.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X800.00 Y800.00 Z30.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z3200 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.722 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 170C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; set temperature limit for heater 1 to 450C

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S450 ; set temperature limit for heater 2 to 450C

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out7" T3 ; create bed heater output on out7 and map it to sensor 3

M141 H3 ; Define heater h7 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C

; Fans

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config override

M572 D0 S0.7 ; enable pressure advance

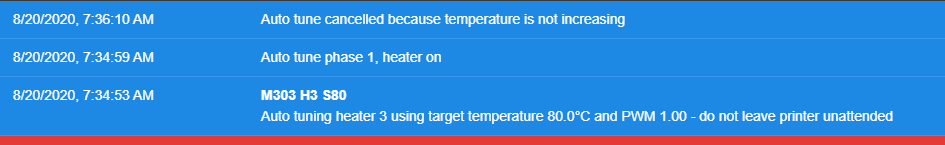

I tried to tune as you suggested:

The SSR has an LED that lights when it is activated and it didn't turn on during tuning. It will activate if I supply voltage to the terminals so I verified it works.

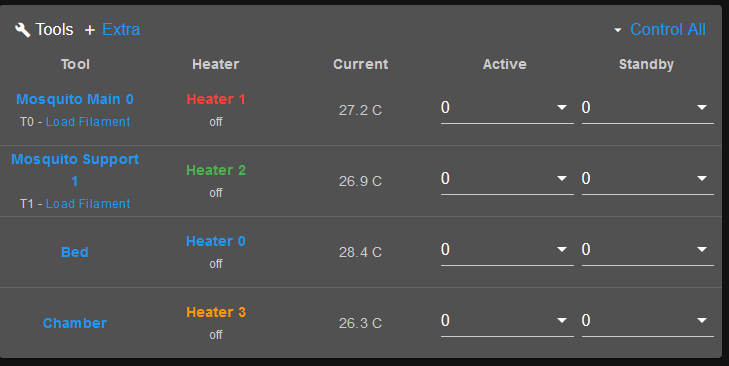

I am trying to get my chamber heater working on my Duet 3. I am using an SSR and if I provide the SSR with voltage it triggers and the heater works. When I try to activate it with DWC, it just faults because there is no change in temp and I get the rising too slowly error.

Here is the relevant section of my config file on the chamber heater:

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out3" T3 ; create bed heater output on out0 and map it to sensor 3

M141 H3 ; Define heater h3 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C

I am using Duet Web Control 3.1.1. Note the temp is correct and reflects change if you manually cycle the ssr.

Any suggestions would be appreciated.

Thanks,

Mark

You nailed it. I had a change in my starting script for simplify that fixed it once removed.

Thanks for the help and mark this solved.

Mark

I cannot run any new files regardless of the name. Only files previously printed. If I attempt to print it just gives the same error. I have tried this multiple times.

The file is really named t.gcode.

It was just a test print file to see if the problem repeats. Every file try to print now fails to print with the same error.

Here is the file

It is duet 3 with sbc: FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet 3 MB6HC v0.6 or 1.0 FIRMWARE_DATE: 2020-05-19b2

Thanks,

Mark

Getting an error now whenever I upload a file to print. old prints previously loaded can run:

Here is the firmware:

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet 3 MB6HC v0.6 or 1.0 FIRMWARE_DATE: 2020-05-19b2

Error:

8/16/2020, 4:14:01 PM M32 "0:/gcodes/t.gcode"

Error: Failed to parse major T-code number (o)

8/16/2020, 4:14:01 PM Upload of t.gcode successful after 0s

config file:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X600.00 Y600.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X120000.00 Y120000.00 Z1200.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X800.00 Y800.00 Z30.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z3200 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.722 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 150C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; max temp for extruder 450c

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 2 as PT1000 on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S3 P"temp3" Y"pt1000" R2200 ; define bed temperature sensor

M950 H3 C"out3" T3 ; create bed heater output on out3 and map it to sensor 3

M141 H3 ; heater 3 is the chamber heater

; Fans

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config override

M572 D0 S0.7 ; enable pressure advance