Trying to get a FolgerTech FT5, R2 kit dialed in

-

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

I'm wondering if I should consider just getting a totally new extruder/hot end assembly that's better engineered.

Couldn't hurt.

I think FT5 stands for Fix That x5

-

@Phaedrux said in Trying to get a FolgerTech FT5, R2 kit dialed in:

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

I'm wondering if I should consider just getting a totally new extruder/hot end assembly that's better engineered.

Couldn't hurt.

I think FT5 stands for Fix That x5

How very dare you, dont you know John Folger thinks he can walk on water.......

-

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

A few thoughts have gone through my mind after reading a few other things here and there. This extruder assembly that was/is "stock" on the FT5 kit is really sort of a bare bones (just enough to get the job done) sort of assembly. There is just one fan involved, and it blows on a heatsink that keeps the upper part of the extruder assembly from being too hot. There is no part cooler fan at all.

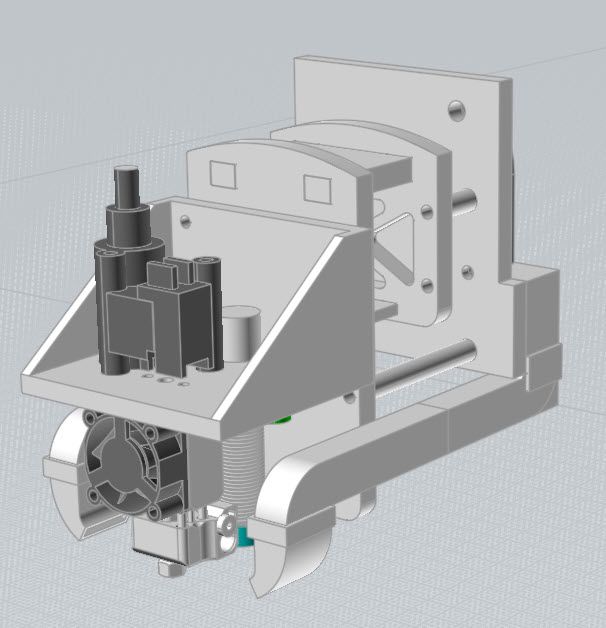

I designed a new extruder assembly for my FT5.

It's simple, allows for different hotends such as a E3Dv6, Mosquito or Dragon and includes part cooling and mounting for a BLTouch v3 or a 12mm Inductive/Capacitive Z probe.

However it is based on using a Zesty Nimble and I'm not sure you can get those at this time.

Frederick

-

@Veti

Since the thermistors I have came from FolgerTech, and you can't ask them any questions, I searched around looking for any posts where somebody seemed to have authoritatively identified and specified the thermistors that were placed in the R2 kits like I have. I found no such post, but that doesn't mean there isn't one to be found someplace.It occurred to me after reading some articles on calibration that perhaps what I should try to do is make measurements and determine a beta value myself. I do have a thermocouple sensor for one multi-meter, and I have another meter I can use for resistance measurements.

I got the hot end plenty hot while I had my thermocouple in there with some thermal grease to help it be more accurate. I then turned off the machine and quickly transferred the thermistor leads to my meter. Now, it was just a matter of taking occasional readings as it cooled down. I even got a reading below ambient room temperature by holding an ice cube against the hot end block when it wasn't going to get any cooler on its own.

I used the readings at 28 Deg C and 217 Deg C along with the resistance readings of 86800 ohms and 500 ohms. Plugging that data into the formula resulted in an experimentally calculated beta of 4022.

For now, that's what I have in my config.g now. For the moment, I'm going to assume this is also valid for the bed thermistor, but I may test that later.

-

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

4022

I'd venture that the actual value is 3950 as that is a very common value for NTC thermistor.

-

@Phaedrux said in Trying to get a FolgerTech FT5, R2 kit dialed in:

... and maybe some over extrusion as well.

I'm thinking that too. I followed that link to the calibration page you suggested. Down near the end was the "Method 1" using the 100 mm x 100 mm very thin walled cube. Experimenting with various settings in DWC of the extrusion factor caused me to settle initially on a value of 77%.

That seemed like quite a significant adjustment to be making, but I went ahead and revised the extruder estep value in config.g and printed another Benchy boat. The attached photo shows considerable improvement, that's for sure.

It surprised me that my first extruder estep adjustment made by my measuring actual filament distance moved into the extruder when requesting 100 mm of extrusion would be subject to a second adjustment so large.

I still think I need to get a better extruder and/or hot end. It doesn't seem to me like the stock extruder grips the filament quite as securely as I would like.

-

@Phaedrux said in Trying to get a FolgerTech FT5, R2 kit dialed in:

Couldn't hurt.

I think FT5 stands for Fix That x5I think I'm ready to improve the extruder assembly on this printer. The stock extruder just has a single toothed drive gear and a spring actuated roller to press the filament against the drive gear. The grip just isn't that good. Sometimes, when I start a print, after the bed probing is done, the gantry goes to the start point, the extruder starts moving, and filament immediately pops out off the top of the extruder.

Also, when that does not happen, and the print actually starts, it often seems like the filament is so late in starting to come out of the nozzle that a fraction of the first layer of the actual part might be missing. It seems like I need to have something in the "Start g-code" section of Cura to make the nozzle do an extra lap around the outside of the part before it begins for real. I'm not sure how to do that.

I've seen some videos about assembling the parts needed to retrofit something like the E3D extruder and hot end that involve sourcing some milled aluminum parts from 713maker.com. It seems that they are out of stock on their aluminum extruder mounting plates, so I'd need to look elsewhere for the mounting bits.

Has anybody here got a suggestion for a source for what's needed? The aluminum parts looked nice, but thingiverse may offer 3D printed parts to do this as well. I will look around.

-

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

Has anybody here got a suggestion for a source for what's needed? The aluminum parts looked nice, but thingiverse may offer 3D printed parts to do this as well. I will look around.

My mount is designed for the 713 parts. I've never had to wait long for them.

The issue with my design is that it uses a Zesty Nimble and I don't know if they are shipping.

Attached is the version for a Mosquito Hotend and a 12mm Inductive Z-Probe.

Frederick

-

That sounds like a form of the MK8 extruder. https://reprap.org/wiki/Extruder_assembly

It's a bit primitive these days but it's cheap and functional. If you used that calibration guide I linked you should be able to find your maximum flow rate and as long as you stay within that limit you should be able to get decent results with it. Upgrading to some form of geared extruder would be worthwhile. Direct drive or bowden.

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

section of Cura to make the nozzle do an extra lap around the outside of the part before it begins for real. I'm not sure how to do that.

You can add a nozzle prime line to the start gcode section, or you can use the skirt function (under the bed adhesion heading) which adds a number of loops around the outside of the part on the first layer to ensure there is plastic flowing.

Example of a nozzle prime macro:

;M98 P"0:/sys/PrimeNozzle.g" G90 ; Absolute positioning G1 X1 Y270 F6000 ; Move to front left corner M400 ; clear movement buffer M116 ; Wait for temps G1 Z0.3 F100 ; Move Z to prime height G91 ; Relative positioning M83 ; Relative extrusion G1 E5 F300 ; pre-prime nozzle G1 X40 E10 F300 ; Prime line G10 ; Retract G1 Y-1 X1 F10000 ; Wipe nozzle M400 -

@Phaedrux said in Trying to get a FolgerTech FT5, R2 kit dialed in:

That sounds like a form of the MK8 extruder.

Yes, the pictures in your link are almost a perfect match for what FolgerTech included in my kit.

You can add a nozzle prime line to the start gcode section, or you can use the skirt function.

I worked a bit with both of those suggestions. I tried putting the g-code commands in the section to be applied before each print, but it didn't work as expected. The nozzle came over the the front right, seemed to try and extrude a little (nothing came out), then it traveled over to the front left, and extruded a big doughnut of PLA that just surrounded the nozzle since it wasn't moving. Rather than troubleshoot that immediately, I moved on to your second suggestion.

I had been slicing using something called the "Cura Engine" accessible to be through Repetier. That slicer has no "skirt" function. It has brim and raft, but not skirt. I then looked at Cura 4.7. That of course had the skirt function plus a hugh bunch of new confusing things

I sliced the 20 mm calibration cube and sent it to the printer. The results were not good.

I sliced the 20 mm calibration cube and sent it to the printer. The results were not good.I had a bad first layer really, some of the corners start to lift off, and there was a persistent corruption of one of the sides of the cube near one of the corners, pretty much all the way up. Photo attached; not sure what happened, and it was repeatable.

I also have Slic3r accessible through Repetier, and I just downloaded their latest version as well. Of all the slicers I've fooled with so far, the interface on Slic3r is my favorite. It made a good calibration cube, and it had a very functional and easy to configure skirt function.

As for the remark I made in another post about the filament springing out when I would start another job, I have partially tracked that down. The extruder motor was definitely going in reverse after a print finished, and it felt like it was running quite a while (probably would have ejected 100 mm if there had been that much to retract). I have not located the g-code yet that was doing that. When I printed the cube sliced by Slic3r, the extruder did not do that at the end of the print.

-

You may want to try Prusa Slicer as well.

-

Yes, that is on my list as well.

Since I am getting some of the "Extruder Issues" somewhat resolved and understood, I may move forward for a while with this MK8 configuration since it does work. I think the priority right now is to arrange for a "part cooler" fan system.

BTW, I was talking with a friend today about his 3D printing adventures. He has a Creality CR10, and he made some remarks about wanting to upgrade his mainboard at some point. I gave him a glowing review of the Duet3D line.

I came here because of all the miserable issues I had with compiling Marlin. I could not get it to work; compiles always failed, and the error messages were really aimed at somebody who was a full blown coder (which I am not).

I am also planning to get clear acrylic panels laser cut so I can enclose the FT-5. The fact it's already a nice box framed with extrusions, and nothing major tries to "poke out" of the rectangular solid shape it is, makes it an easy device to put walls on. I'm sure many here have enclosed their printers in various creative ways

-

@Phaedrux said in Trying to get a FolgerTech FT5, R2 kit dialed in:

I'd venture that the actual value is 3950

I think you are right. Now that I know that things that look exactly like my hot end appear as kits on Amazon searchable as MK8, some of those mention as the thermistor description "NTC 3950 100K Thermistor".

I'm wondering if the bed thermistor that FolgerTech put in my kit is likely to be the same or not.

BTW, I did do the tests to determine the maximum extrusion rate at 210 Deg C, and I came up with a volumetric limit of 8 cu-mm/sec, and thus a max printing speed for 0.2 mm layer height and 0.4 mm layer width of 100 mm/sec.

-

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

I'm wondering if the bed thermistor that FolgerTech put in my kit is likely to be the same or not.

Quite likely. You can get NTC 3950 100K Thermistors in bags of 10000, so if they use it for one, chances are they use it for all. Since displayed temp accuracy isn't critical for 3d printers it's a suitable thermistor, but you'll need to PID tune and then do some experimenting to find the best set temps.

@bjackson said in Trying to get a FolgerTech FT5, R2 kit dialed in:

I did do the tests to determine the maximum extrusion rate at 210 Deg C, and I came up with a volumetric limit of 8 cu-mm/sec, and thus a max printing speed for 0.2 mm layer height and 0.4 mm layer width of 100 mm/sec.

That sounds reasonable. Now that you know the limit of the hotend, the limit of the motion system for best quality will likely be below that unless ringing and other visual defects aren't important.