problem with irregular bltouch mesh

-

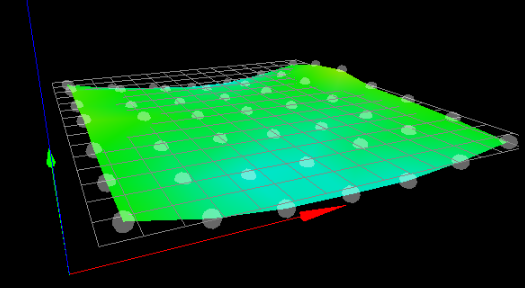

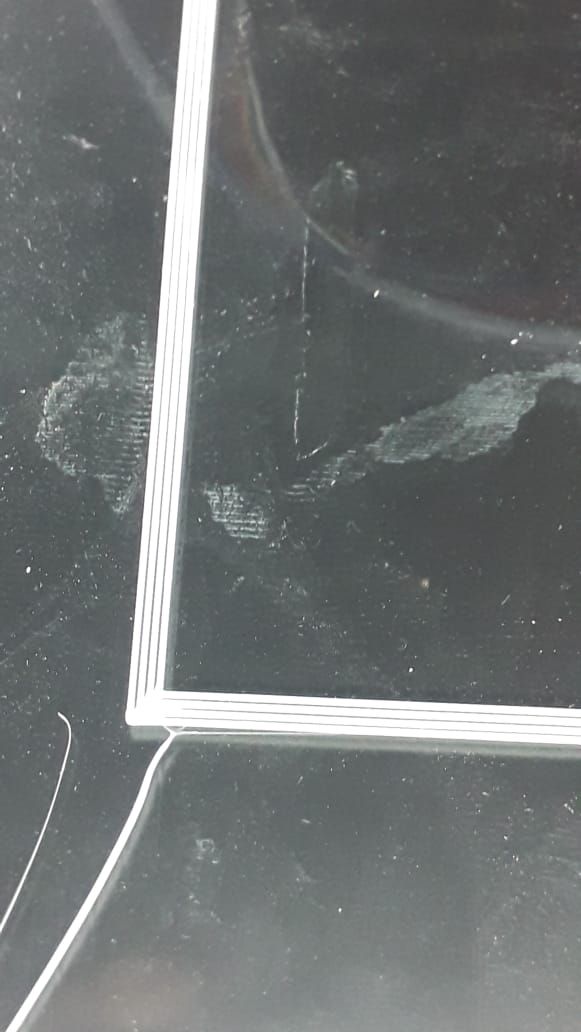

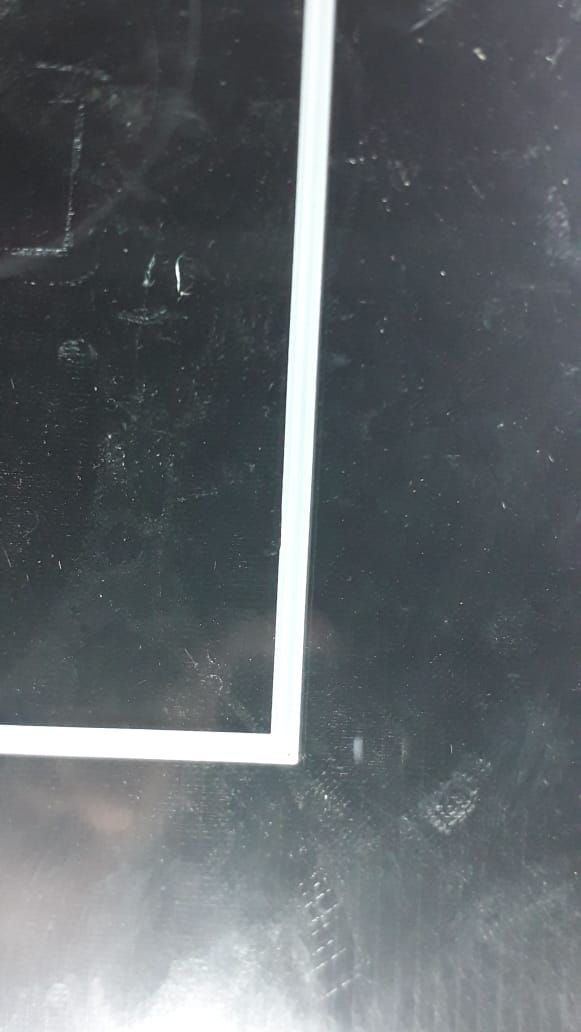

I now send photos of a test that I do, there are some squares inside each other, with 0.4mm space between them, the largest square is 280mm, line height is 0.3mm, the motors compensate according to the mesh generated by bltouch but in practice the layer is irregular.

-

RepRapFirmware height map file v2 generated at 2020-09-30 16:08, min error -0.121, max error 0.077, mean -0.034, deviation 0.048

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum

15.00,285.00,25.00,295.00,-1.00,45.00,45.00,7,7

0.007, -0.064, -0.099, -0.105, -0.106, -0.070, -0.015

-0.006, -0.064, -0.111, -0.105, -0.056, -0.029, 0.005

0.005, -0.038, -0.045, -0.073, -0.076, -0.048, 0.020

0.045, 0.017, -0.021, -0.036, -0.039, -0.034, 0.025

0.030, -0.015, -0.033, -0.040, -0.028, 0.010, 0.077

0.040, 0.006, -0.025, -0.058, -0.059, -0.014, 0.050

0.000, -0.065, -0.096, -0.121, -0.119, -0.076, -0.011

-

Thanks.

Try printing a test from 50 to 250 on both X and Y.

That should put it away from the edges which are the highest parts.

Frederick

-

@fcwilt

print centered 200mm squares

edge x50,y50

edge x200,y50

-

Thanks.

It looks a bit better.

Did you create the height map with the bed heated to a typical temperature you would commonly use?

If not try re-creating the height map with the bed heated.

Frederick

-

@fcwilt

yes, i have 3 height maps created for each material i use, at different temperatures, and i update them almost every day -

Are you sure your probe offsets are correct?

-X to the left of the nozzle, +X to the right

-Y to the front of the nozzle, +Y to the back -

@Phaedrux yes this is correct, thanks for the tip. I've really looked at a lot, the reprap code is not so complicated now for me but I still don't know what may be happening. can speed, acceleration or jerk on the z axis influence?

-

@RODOKAS said in problem with irregular bltouch mesh:

M574 Z1 S1 P"zstop+e1stop"

Are you doing independent lead screw leveling as well?

@RODOKAS said in problem with irregular bltouch mesh:

M350 X16 Y16 Z16:16 E16 I1 ; Micropassos cem interpolação M92 X80.00 Y80.00 Z800.00:800.00 E416,5 ; set steps per mm M566 X400.00 Y400.00 Z60.00:60.00 E2000.00 P1 ; set maximum instantaneous speed changes (mm/min) JERK M203 X12000.00 Y12000.00 Z720.00:720.00 E2100.00 ; set maximum speeds (mm/min) M201 X2300.00 Y2300.00 Z240.00:240.00 E9000.00 ; set accelerations (mm/s^2) ;M204 P2600 T2000 ; set accelerations travel (mm/s^2) M906 X1150 Y1150 Z1150:1150 E700 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S20 ; Set idle timeout

Where you have double Z values you shouldn't. The Z axis is a single axis, so remove the double values. Ex: Z1150:1150

E416,5

Your E steps per mm has a comma instead of a period.

Can you send M98 P"config.g" and post the results?

Also post your homeall and your slicer start gcode.

-

@Phaedrux

my steps are really wrong, thanks!

should I remove all double settings for the second z?

yes, I do the leveling by optical endstop on each axis then I do it again by bltouch.I made corrections

M98 P"config.g"

HTTP is enabled on port 80

FTP is enabled on port 21

TELNET is disabled

Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 205C

Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 676C

Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 205C

Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 676C; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.1 on Fri Jun 05 2020 16:15:12 GMT-0300 (Horário Padrão de Brasília) G91 ; relative positioning G1 H2 Z2 F900 ; lift Z relative to current position G1 H1 X-305 Y-315 F6000 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-305 ; home X axis G1 H1 Y-315 ; home Y axis G1 X3 Y3 F6000 ; go back a few mm G1 H1 X-305 F600 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-315 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X5 Y5 F6000 ; go to first bed probe point and home Zstart script

G28 ;

; Filament gcode

G29 S1 P"ABS.CSV"; Carrega malha para ABS

G1 X5 Y1 Z0.2 F9000;

G92 E0; Reset no extrusor

G1 E20 F1000.0 ; comeca a limpeza

G1 X7.0 F100

G1 X80.0 E23 F2000.0 ; Termina de fazer a limpeza

G92 E0;

M572 D0 S0.05; avanco de pressao reprap

;M593 F40; aceleracao dinamica reprap

;M376 H5; altura para diminuir a compensacao da mesaprusa slicer

-

@RODOKAS said in problem with irregular bltouch mesh:

should I remove all double settings for the second z?

Yes. It's not really a second Z. There is only 1 Z axis, even if made up of multiple motors. If you want to control the motors separately, you'd need to create an entirely separate axis like U and then you'd have settings for that axis. In fact, before RRF3 you would have needed to do that to do the dual endstop leveling and home each axis separately and then recombine into a single Z axis.

I should have asked for your bed.g as well.

-

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.1.1 on Fri Jun 05 2020 16:15:10 GMT-0300 (Horário Padrão de Brasília) M561 ; clear any bed transformThanks!

-

@Phaedrux

this is the macro I use to read and create the mesh for ABS;macro /macros/__prepare_ABS.g prepare the machine after a cold start for ABS printing T0 ; define tool M190 S95 ; Set the bed temperature at 95°C and wait for it G28 ; home G29 S2 ; Limpa a malha G29 S0 ; executa leitura da cama G29 S3 P"ABS.csv" ; salva a leitura como ABS G29 S1 P"ABS.csv" ; carrega a malha ABS G1 X5 Y5 F7200 M500; -

@RODOKAS said in problem with irregular bltouch mesh:

this is the macro I use to read and create the mesh for ABS

;macro /macros/__prepare_ABS.g prepare the machine after a cold start for ABS printing T0 ; define tool M190 S95 ; Set the bed temperature at 95°C and wait for it G28 ; home G29 S2 ; Limpa a malha G29 S0 ; executa leitura da cama G29 S3 P"ABS.csv" ; salva a leitura como ABS G29 S1 P"ABS.csv" ; carrega a malha ABS G1 X5 Y5 F7200 M500;Hi,

- It doesn't seem as if your homing macro is setting the Z=0 datum using G30

- As I recall you don't need to use G29 S2 right before using G29 S0 - it won't cause problems if you leave it

- You don't need to use G29 S1 to load the just created height map, the map is still active

- What is the point of the M500?

Frederick

-

I was curious about the m561 in my beg.g and took it out to test it, did the mesh in abs again and restarted the machine to make sure, I did the same print test as before and the result was the same.

-

Your homeall doesn't have a z homing component, so please post homez as well.

Where are you doing the Z axis leveling? In homez?

Could you post all of your files in a single post? That would make it much easier to see what's going on without having to scroll around all over the place. The only way we can see what's going on is be looking at the gcode.

-

@Phaedrux you are right, i will put all gcodes here.

;config.g ; Configuration file for Duet WiFi (firmware version 3) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"3DPRINT" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network ;M552 S2 ;Habilitar ponto de acesso M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S0 ; desabilitado Telnet ; Drives M569 P0 S0 F3 ; physical drive 0 goes forwards M569 P1 S0 F3 ; physical drive 1 goes forwards M569 P2 S1 F3 ; physical drive 2 goes backwards M569 P3 S1 F3 ; physical drive 3 goes backwards M569 P4 S1 ; physical drive 4 goes backwards M584 X0 Y1 Z2:3 E4 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; Micropassos cem interpolação M92 X80.00 Y80.00 Z800.00 E416.5 ; set steps per mm M566 X400.00 Y400.00 Z60.00 E2000.00 P1 ; set maximum instantaneous speed changes (mm/min) JERK M203 X12000.00 Y12000.00 Z720.00 E2100.00 ; set maximum speeds (mm/min) M201 X2300.00 Y2300.00 Z240.00 E9000.00 ; set accelerations (mm/s^2) ;M204 P2600 T2000 ; set accelerations travel (mm/s^2) M906 X1150 Y1150 Z1150 E700 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S20 ; Set idle timeout ; Z-Probe M98 P"0:/macros/configuracao_sonda" ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A180.2 C510.1 D2.9 S0.75 V12.8 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S115 ; set temperature limit for heater 0 ;M308 S1 P"e0temp" Y"thermistor" T100000 B4267 ; configuração conforme opção 5 do marlin M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C0.0000000706 ; configuração conforme recomendação do duet3d M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ;M307 H1 B1 ; ativa o modo bang bang M307 H1 A651.7 C191.8 D6.3 S1.00 V12.7 B0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; seta o limite de temperatura para o extrusor ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"fan0" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned on ;M950 F1 C"fan1" Q500 ; create fan 0 on pin fan0 and set its frequency ;M106 P1 C"PLACA" S1 H1 T40 ; set fan 0 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q200 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"FONTE" S0.8 H1 T180 ; set fan 2 name and value. Thermostatic control is turned off M950 F1 C"e1heat" Q500 ; create fan 1 on pin HEATER2 and set its frequency M106 P1 C"HOTEND" S1 H1 T60 ; set fan 1 name and value. Thermostatic control is turned off ; Axis Limits M208 X-3 Y0 Z0 S1 ; set axis minima M208 X300 Y300 Z345 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S1 P"zstop+e1stop" ; Tools M563 P0 D0 H1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Miscellaneous M911 S11 R11.5 P"M913 X0 Y0 G91 M83 G1 Z1 E-2 F1000" ; set voltage thresholds and actions to run on power loss M501; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.1 on Fri Jun 05 2020 16:15:12 GMT-0300 (Horário Padrão de Brasília) G91 ; relative positioning G1 H2 Z2 F900 ; lift Z relative to current position G1 H1 X-305 Y-315 F6000 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-305 ; home X axis G1 H1 Y-315 ; home Y axis G1 X3 Y3 F6000 ; go back a few mm G1 H1 X-305 F600 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-315 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X5 Y5 F6000 ; go to first bed probe point and home Z; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.1.1 on Fri Jun 05 2020 16:15:12 GMT-0300 (Horário Padrão de Brasília) G91 ; relative positioning G1 H1 Z-350 F900 ; move Z down until the endstop is triggered G1 Z3 F900 G1 H1 Z-5 F150 G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G1 H1 Z3 F900 G1 Z2.9 G30; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.1.1 on Fri Jun 05 2020 16:15:10 GMT-0300 (Horário Padrão de Brasília) ;M561 ; clear any bed transform;macro /macros/__prepare_ABS.g prepare the machine after a cold start for ABS printing T0 ; define tool M140 S95 ; Set the bed temperature and don't wait for it M190 S95 ; Set the bed temperature at 95°C and wait for it G28 ; home G29 S2 ; Limpa a malha G29 S0 ; executa leitura da cama G29 S3 P"ABS.csv" ; salva a leitura como ABS G29 S1 P"ABS.csv" ; carrega a malha ABS G1 X5 Y5 F7200 M500;I really don't know if the M500 makes a difference at the end of the ABS macro

-

@RODOKAS said in problem with irregular bltouch mesh:

I really don't know if the M500 makes a difference at the end of the ABS macro

It doesn't do anything in this case because there hasn't been anything calculated or measured to save to config-override.g.

-

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.1.1 on Fri Jun 05 2020 16:15:12 GMT-0300 (Horário Padrão de Brasília) G91 ; relative positioning G1 H1 Z-350 F900 ; move Z down until the endstop is triggered G1 Z3 F900 G1 H1 Z-5 F150 G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G1 H1 Z3 F900 G1 Z2.9 G30Your homez could be improved. The endstop leveling proceeds correctly, but then it gets a bit odd.

Remove this part

G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G1 H1 Z3 F900 G1 Z2.9 G30And replace it with

G1 Z3 ; raise for clearance G1 X150 Y150 ; move to center G30 ; probe the bedProbing the center of the bed is important for setting Z0 since you are adjusting the tilt of the bed. You want to measure the center of that tilt.

You're also only using the endstops for tilt correction. You aren't using the probe anywhere. This is fine as long as the endstop positions are accurate to remove any tilt.

See here for how you would use the probe to correct for tilt.

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

This would normally be done in G32/bed.gCan you please post this macro s well: M98 P"0:/macros/configuracao_sonda"

Then in your prepare_abs macro to generate the heightmap you would have G28 to home the bed, G32 to level the tilt with the probe, and then G29 to create a heightmap of the bed surface.

-

@Phaedrux

I'm sorry I forgot that I leave the probe configuration in a macroM950 S0 C"exp.heater3" ; criar servo / gpio 0 no aquecedor de 3 pinos no conector de expansão M558 P9 C"^zprobe.in" R0.2 H2.8 F60 T10800 ; BLTouch conectado ao pino de entrada da sonda Z G31 P500 X-4.5 Y25 Z0.55 ; deslocamento da sonda com o bico M557 X20:280 Y30:290 S50 ; define mesh gridif my z-axis is a little unbalanced, it can hit, so I don’t think it’s safe to probe the center of the bed and then probe the bed close to the engines, maybe if I did all that I mentioned after using the endstop I already have it would make it safer.

I will try this change and then put the result.would my new abs mesh macro look like this?

;macro /macros/__prepare_ABS.g prepare the machine after a cold start for ABS printing T0 ; define tool M190 S95 ; Set the bed temperature at 95°C and wait for it G28 ; home G29 S0 ; executa leitura da cama G29 S3 P"ABS.csv" ; salva a leitura como ABS G1 X5 Y5 F7200;