First Post & few Questions (Low+High Endstop & Blobs Issue)

-

Hello Veti,

this are direct driven extruder from an old printer. I took it from 5 old printers where the printbed was srewed (a dobot replica,singma XGM-5a: https://item.jd.com/32249923157.html)

I reused the steppermotors and the extrudermechanism. The other parts are from doltmechatronik.de and reprap.me.

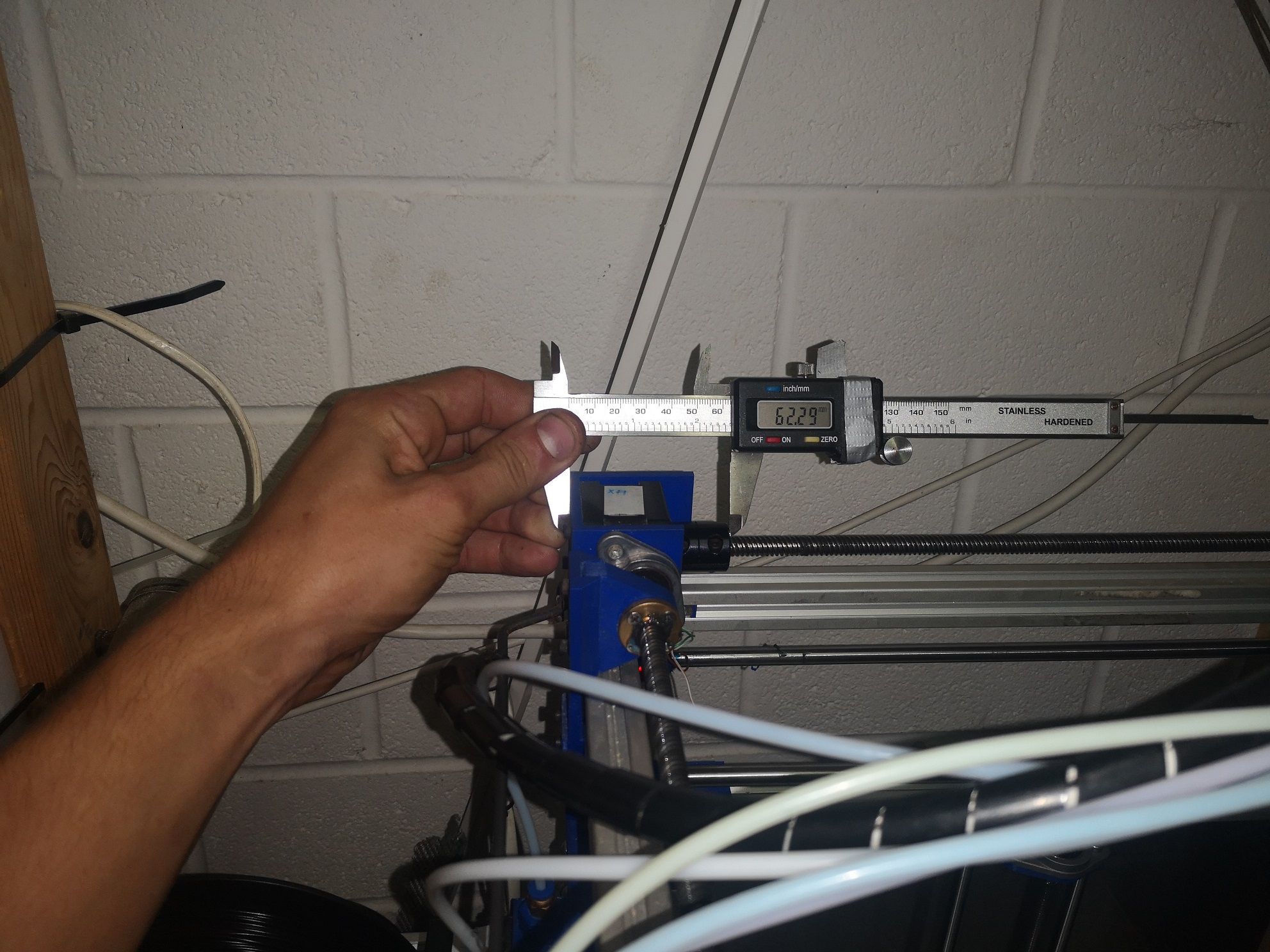

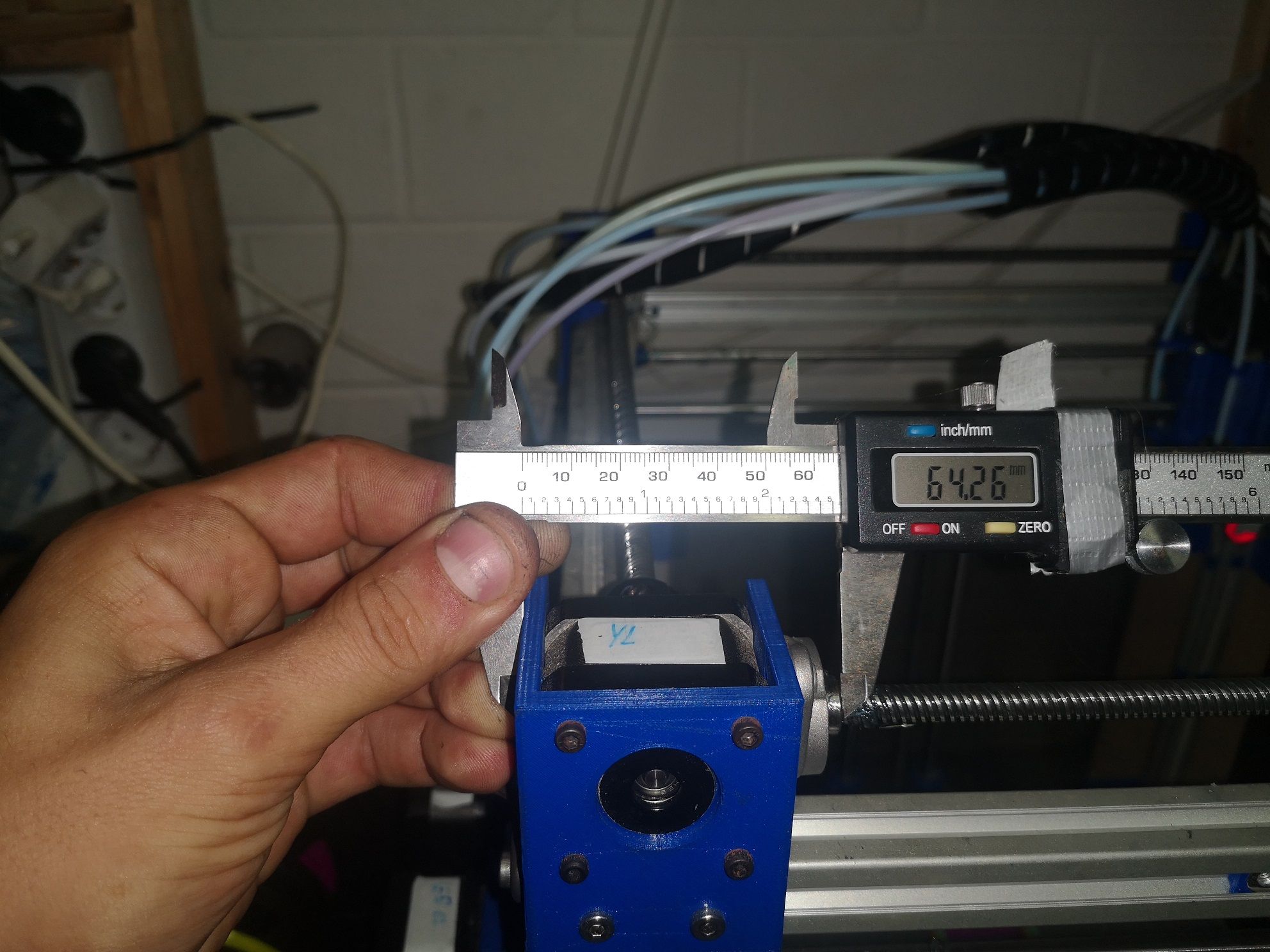

E85.6:85.6:85.6:85.6:85.6 is a weird number, but i callibrated the exdruder like that and it worked fine.The reason i want to use high and low endstops is, that i want the printer to synchronise during homing not while printing. I can adjust it manualy but that is not my goal. There is a diffrence of 2 mm at the end of one leadscrew and at the beginning of the other.

I also already tried to rewrite the homeall.gcode, but it never triggered the second endstop. Now it just uses one an then stops.

It also works fine, but sometimes it blocks and the movement aren't parallel anymore.

Thanks for the tip of backlach, for now this isn't prior. But I'll change it in the future.

I've tried to put the endstops togeter at the M574 code but it didn't work.

You said that I could change the endstopbehaviour by the fly. So that means, I can put a remap after the first endstop is triggered in the home code?Here is a picture to explaine my idea:

At low speed it works good but at high it blocks sometimes.

I took out the thermistor setup because the post got over 20000 letters. I'll repost it.

I'll put it now here:0:/sys/config.g ; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Sep 09 2020 22:34:20 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"FIP" ; set printer name M111 S1 ; G21 ; M555 P1 ; ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Driver mapping M584 X1:2 Y10:11 Z0:3:4 U2 V11 W3 A4 E5:6:7:8:9 P3 ; set drive mapping M671 X150:-25:325 Y325:-25:-25 S1 ; leadscrews at rear middle, front left and front right ; Drives M569 P2 S0 ; physical drive 2 goes forwards M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M569 P5 S0 ; physical drive 5 goes forwards M569 P6 S0 ; physical drive 6 goes forwards M569 P7 S0 ; physical drive 7 goes forwards M569 P8 S0 ; physical drive 8 goes forwards M569 P9 S0 ; physical drive 9 goes forwards M569 P10 S0 ; physical drive 10 goes forwards M569 P11 S1 ; physical drive 11 goes forwards M350 X16 Y16 Z16 E16:16:16:16:16 I1 ; configure microstepping with interpolation M92 X400.00 Y400.00 Z2133.33 E85.6:85.6:85.6:85.6:85.6 ; set steps per mm M566 X2000.00 Y2000.00 Z100.00 E2000.00:2000.00:2000.00:2000.00:2000.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z900.00 E4000.00:4000.00:4000.00:4000.00:40000.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z100.00 E2500.00:2500.00:2500.00:2500.00:2500.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1000:1000:1000:1000:1000 I80 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 U0 V0 W0 A0 S1 ; set axis minima M208 X300 Y300 Z270 U300 V300 W270 A270 S0 ; set axis maxima ; Endstops M584 X1:2 Y10:11 Z0:3:4 U2 V11 W3 A4 E5:6:7:8:9 ; M574 X2 S1 P"ystop" ; configure sensorless endstop for low end on X M574 Y2 S1 P"connlcd.encb" ; configure sensorless endstop for low end on Y M574 Z1 S1 P"xstop+e0stop+e1stop" ; configure sensorless endstop for low end on Z M574 U1 S1 P"zstop" ; M574 V1 S1 P"connlcd.enca" ; ; Z-Probe M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y-35 Z1.8 ; set Z probe trigger value, offset and trigger height M557 X35:265 Y35:265 S230 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" A"Printbett" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bed_heat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A26.7 C106.8 D2.4 S1.00 V23.8 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 S65 R65 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"duex.e6temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin duex.e6temp M950 H1 C"duex.e2heat" T1 ; create nozzle heater output on duex.e2heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; M308 S2 P"duex.e2temp" Y"thermistor" A"Mosfet" T100000 B4138 ; configure sensor 1 as thermistor on pin duex.e6temp M950 H2 C"duex.e2temp" T2 ; create nozzle heater output on duex.e2heat and map it to sensor 1 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S3 P"duex.e3temp" Y"thermistor" A"Y-Driver" T100000 B4138 ; configure sensor 1 as thermistor on pin duex.e6temp M950 H3 C"duex.e3temp" T3 ; create nozzle heater output on duex.e2heat and map it to sensor 1 M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S4 P"duex.e4temp" Y"thermistor" A"Duet & Duex" T100000 B4138 ; configure sensor 1 as thermistor on pin duex.e6temp M950 H4 C"duex.e4temp" T4 ; create nozzle heater output on duex.e2heat and map it to sensor 1 M307 H4 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"duex.fan6" Q500 ; create fan 0 on pin duex.fan3 and set its frequency M106 P0 H-1 C"Part-Cooling" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"duex.fan4" Q500 ; create fan 1 on pin duex.fan4 and set its frequency M106 P1 S1 H2 T30:40 C"Mosfet" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"duex.fan5" Q500 ; create fan 2 on pin duex.fan5 and set its frequency M106 P2 S1 H3 T25:40 C"Y-Driver" ; set fan 2 value. Thermostatic control is turned on M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan6 and set its frequency M106 P3 S1 H4 T30:40 C"Duet & Duex" ; set fan 3 value. Thermostatic control is turned on M950 F4 C"duex.fan7" Q500 ; create fan 4 on pin duex.fan7 and set its frequency M106 P4 S1 H1 T40:50 C"Hotend-Carriage" ; set fan 4 value. Thermostatic control is turned on M950 F5 C"duex.fan8" Q500 ; create fan 5 on pin duex.fan8 and set its frequency M106 P5 S1 H1 T40:50 C"Hotend-Carriage" ; set fan 5 value. Thermostatic control is turned on ; Tools ; Tools ; P tool number ; D Extruder drive ; H Heater toolsetup deleted, see config at the first post ; Enable Firmware retraction ; Snnn positive length to retract, in mm ; Rnnn positive or negative additional length to un-retract, in mm ; Znnn additional zlift/hop M207 S8 F4000 ;set firmware retraction ; Sets filament diameter for all extruders, which also enables volumetric printing M572 D0:1:2:3:4 S0.8 ; M200 D1.75 ; set all extruder filament diameters to 1.75mm ; Custom settings are not definedhere's the homeall.gcode

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Wed Sep 09 2020 22:34:21 GMT+0200 (Mitteleuropäische Sommerzeit) G91 ; relative positioning G1 H1 Z10 F900 ; lift Z relative to current position G1 H1 X320 U320 Y320 V320 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-10 U-10 Y-10 V-10 F360 ; G1 H1 X15 U15 Y15 V15 F360 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z250 F900 ; lift Z relative to current position G1 H1 Z5 F360 ; move Z down stopping at the endstop G1 H2 Z-15 F360 ; lift Z relative to current position G1 H1 Z20 F360 ; move Z down stopping at the endstop G1 H2 Z-255 F900 ; lift Z relative to current position G1 H2 X-150 U-150 Y-150 V-150 F6000 ; go back a few mm G90 ; G92 X150 Y150 Z6.8 ;Thank you for your reply

FITT

-

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

B4138

your thermistors are not setup correctly. B4138 is the default.you will need to look up the beta value for the thermistors that you are using.

since you are already relying on motors blocking, why not put a shim on one side and use stall detection? that way you only need to home on one side.

-

I'll look up for the value for the thermisor. I tuned the bedthermistor once, and all the other are the same brand. Do I have to put the special configuration at all thermistors ?

The idea with the shime is good, but I can also take the steppercoupling out for 2 mm and get the same effect.

I dismissed the idea of stalldetection because i thought it could destroy the stepperholding due to much vibrations. Or it would press leadscrew out of the bearing and so it won't be precise enough. I never tried it.

Is stalldetection even precise enough? -

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

Is stalldetection even precise enough?

for x and y it does not matter (unless you need restart after power failure)

because if the print is shifted by a fraction of a millimeter on the buildplate it does not matterdo you have the make of the thermistor?

-

@Veti said in

for x and y it does not matter (unless you need restart after power failure)

because if the print is shifted by a fraction of a millimeter on the buildplate it does not matterOk.thank you, I'll give it a try.

Isn't the torque to high for a PLA Holding?@Veti said in

do you have the make of the thermistor?

No I don't. I also reused them from the old printers.

-

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

Isn't the torque to high for a PLA Holding?

generally you reduce the motor current while doing stall detection

see

https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homing@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

No I don't. I also reused them from the old printers.

do you have the marlin value you set?

-

@Veti said in First Post & few Questions (Low+High Endstop & Blobs Issue):

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

Isn't the torque to high for a PLA Holding?

generally you reduce the motor current while doing stall detection

see

https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homingOk. I'll take a look and will give it a try.

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

No I don't. I also reused them from the old printers.

do you have the marlin value you set?

Do you mean this value?

A26.7 C106.8 D2.4 S1.00 V23.8 B0 -

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

Do you mean this value?

no something like this

#define TEMP_SENSOR_0 1

from Configuration.h -

No i don't have something like this

-

@FITT Ref the blobs - Diamond hot ends suffer from filament oozing more than "normal" hot ends. I think it's somehow related to there being multiple melt chambers. High retraction helps but then you run the risk of pulling molten filament up past the heat break zone where it will solidify and cause a blockage.

A couple of things you can try.

- Print at the lowest temperature that you can get away with. In my experience, with a Diamond hot end, this is at, or even below, the minimum recommended for the filament. I used to print PLA at 180 deg C with 5 colour Diamond but print a temperature tower to find what works best on your machine.

- Use the fastest non-print travel move speed that you can. I run at 350mm/sec but I doubt you'd be able to get that high with screw driven axes so run as fast as you can. Anything that will reduce the time the hot end sits at a particular spot will help - so don't use Z hop on retraction (I see you aren't).

-

The strange oozing behaviour is something i have seen a lot. But during a layer there is no probleme while i made my last printtests. It's just at the beginning.

I've already reset the retraction to 2 mm an it still works fine.There were other issues that made me think that i have to set it higher, but now i know better. (like you said, high retraction caused blockage)

It also made that other filament melted into a layer where they didn't belong.

I'm also concerned about the pressure advance. As i can see on my testcubes, the printer has issues to extrude the same amount of filament after a corner. And i think it slows down the printhead?- Your proposes:

1.This is a good point, i printed PLA with 215 degrees but as it looks it was a mistake. The PLA i have melts at 190 degree so i put it now at 195.

- That was also my toughts, so ill tri to make it faster, for now i'm at 75mm/s while printing and the fastest non printing move i tried was 130mm/s.

- Speed:

This is why i'm asking for the high&low endstops. So it would synchronize and would be more accurate for higher speed.

If i'm right the stepper can move faster and have more torque due to 24V?

@Veti do you think that the blobs come from a fault temperature mesuring?

-

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

do you think that the blobs come from a fault temperature mesuring?

if you have the wrong thermistor setting the displayed temperature can easily be off by 20 or more degrees from the real temperature

-

Ok. I'll redo an PID tuning, maybee i've made an error during my lest tuning.

-

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

Ok. I'll redo an PID tuning, maybee i've made an error during my lest tuning.

no .

pid tuning wont help with showing the correct temperature.

only the correct beta value will do that. -

Would it help if i mesure the resistance of the thermisto to gett an approximate value?

-

yes

measure the resistance at room temperature.

then measure the resistance at 100C

then measure the resistance at 200Cyou will need a thermometer or other tool to determine the temperature. do not measure the temperature using the same thermistor.

then plug in those 3 sets of values into the calculator (click on the beta value and select custom)

https://configtool.reprapfirmware.org/Heaters -

ok I'll do it tomorow because the printer is still working now an and still hot.

Roomtemperature 21 or 25 °C? -

@FITT

both work as the value can be calculated from both. -

ok. I see; i didn't click on the beta.

thanks alot @Veti and @deckingman

this helped a lot -

@FITT You should still print a temperature tower as I suggested earlier. Then use the lowest temperature which gives good results according to that tower, regardless of the displayed value.