First Post & few Questions (Low+High Endstop & Blobs Issue)

-

No i don't have something like this

-

@FITT Ref the blobs - Diamond hot ends suffer from filament oozing more than "normal" hot ends. I think it's somehow related to there being multiple melt chambers. High retraction helps but then you run the risk of pulling molten filament up past the heat break zone where it will solidify and cause a blockage.

A couple of things you can try.

- Print at the lowest temperature that you can get away with. In my experience, with a Diamond hot end, this is at, or even below, the minimum recommended for the filament. I used to print PLA at 180 deg C with 5 colour Diamond but print a temperature tower to find what works best on your machine.

- Use the fastest non-print travel move speed that you can. I run at 350mm/sec but I doubt you'd be able to get that high with screw driven axes so run as fast as you can. Anything that will reduce the time the hot end sits at a particular spot will help - so don't use Z hop on retraction (I see you aren't).

-

The strange oozing behaviour is something i have seen a lot. But during a layer there is no probleme while i made my last printtests. It's just at the beginning.

I've already reset the retraction to 2 mm an it still works fine.There were other issues that made me think that i have to set it higher, but now i know better. (like you said, high retraction caused blockage)

It also made that other filament melted into a layer where they didn't belong.

I'm also concerned about the pressure advance. As i can see on my testcubes, the printer has issues to extrude the same amount of filament after a corner. And i think it slows down the printhead?- Your proposes:

1.This is a good point, i printed PLA with 215 degrees but as it looks it was a mistake. The PLA i have melts at 190 degree so i put it now at 195.

- That was also my toughts, so ill tri to make it faster, for now i'm at 75mm/s while printing and the fastest non printing move i tried was 130mm/s.

- Speed:

This is why i'm asking for the high&low endstops. So it would synchronize and would be more accurate for higher speed.

If i'm right the stepper can move faster and have more torque due to 24V?

@Veti do you think that the blobs come from a fault temperature mesuring?

-

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

do you think that the blobs come from a fault temperature mesuring?

if you have the wrong thermistor setting the displayed temperature can easily be off by 20 or more degrees from the real temperature

-

Ok. I'll redo an PID tuning, maybee i've made an error during my lest tuning.

-

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

Ok. I'll redo an PID tuning, maybee i've made an error during my lest tuning.

no .

pid tuning wont help with showing the correct temperature.

only the correct beta value will do that. -

Would it help if i mesure the resistance of the thermisto to gett an approximate value?

-

yes

measure the resistance at room temperature.

then measure the resistance at 100C

then measure the resistance at 200Cyou will need a thermometer or other tool to determine the temperature. do not measure the temperature using the same thermistor.

then plug in those 3 sets of values into the calculator (click on the beta value and select custom)

https://configtool.reprapfirmware.org/Heaters -

ok I'll do it tomorow because the printer is still working now an and still hot.

Roomtemperature 21 or 25 °C? -

@FITT

both work as the value can be calculated from both. -

ok. I see; i didn't click on the beta.

thanks alot @Veti and @deckingman

this helped a lot -

@FITT You should still print a temperature tower as I suggested earlier. Then use the lowest temperature which gives good results according to that tower, regardless of the displayed value.

-

Update:

I've mesured the resistance of the thermistor an succesfully put it into the config.g .

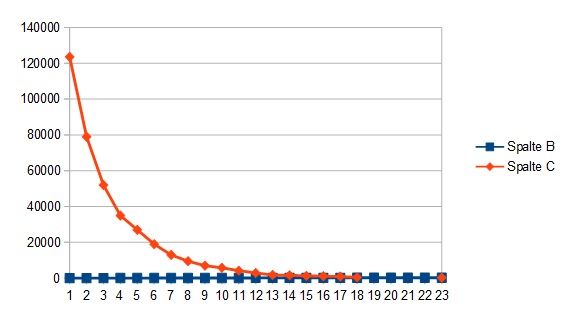

But I had some trubble. I had no thermometer, but I had another printer who still worked fin. so I put the thermistor into the hotend and configured the tempretures at this printer. Then I was able to mesure the resistance of the thermistor. I did it at 10 °c stepps. I putted the results into an excelsheet and could verify if it was a curve at the diagram i made out of the results.

Like that I got this result at the onlineconfigurator:

- T99074 B6026 C2.830042e-7

I put this into my config and run a few printtest just for fun.

Now I'm going to make the temperature tower that @deckingman suggested

Greatings

FITT

-

Update:

I did the temp towers. As you said, it is recomandet tu use the lowest temperature possible; in my case it was 190°C.I just have to set now the stalldetection and everything will be working.

Thanks for your help

FITT

-

@FITT

while that works for now, i would suggest to order some known thermistors anyway.

https://www.aliexpress.com/item/32816085854.html

and

https://www.aliexpress.com/item/32847452724.html -

Hello,

@Veti i'll get some new thermistor in a few days when i order a few more parts that i need. the heater is already new and 24 V.

I'll put a second linearguidance to the diamondcarriage.

I figured out that during the fast print, it moves to much (0.5mm). the printed corners are not straight.Yesterday I scripted a wipetower into prusa. My goal was to evitate oosing colors into the actual printed color while toolchanging. That worked also fine but wasted a lot of fillament. Luckily the printed part was perfect.

I worked with the setup that @deckingman mentioned in his blog (toolsetup: 0.9:0.025:0.025:0.025:0.025....) but the inactiv color oosed somtimes into the actual color.

Today i'm going to ad a servo which will whipe the nozzle and catch the filament which is purged. Like this i'm going to avoid this wipetower an ooze out the unused color at a specific height and befor a toolchange. and prepare the actual tool. -

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

I figured out that during the fast print, it moves to much (0.5mm). the printed corners are not straight.

i was expecting that. that is why i mentioned the igus zero backlash setup.