Dual Hotend setup

-

Good Afternoon, looking for any help, anyone can provide. I have a DIY 3d printer that I have built myself from the ground up. It has all liner rails, dual screw on the z axis and all of this is ran by a DUET maestro. I started with a single hot-end and extruder with a BL Touch and everything printed great am printing on a glass bed also. Every print was dead on and came out perfect. I decided to move to a dual extruder and hot-end. I went with a E3D Chimera, I did swap out the 0.4 nozzles for some 0.6 stainless steel ones (I am not sure if this is part of my problem or not. I have the bed level, my z offset is set. I am printing standard PLA at 210 and have my bed-headed to 60. I am just trying to print a simple 2 color cone, to test everything out. I have both nozzles set to the same z. When I start printing, my first layer is good and sticks well, my first color seems to print ok, but I seem to have a clogged nozzle every time my second color gets ready to go. I keep both hot ends at 210 even in standby, so they are ready to print. I also have a part cooling going after the second layer goes down.

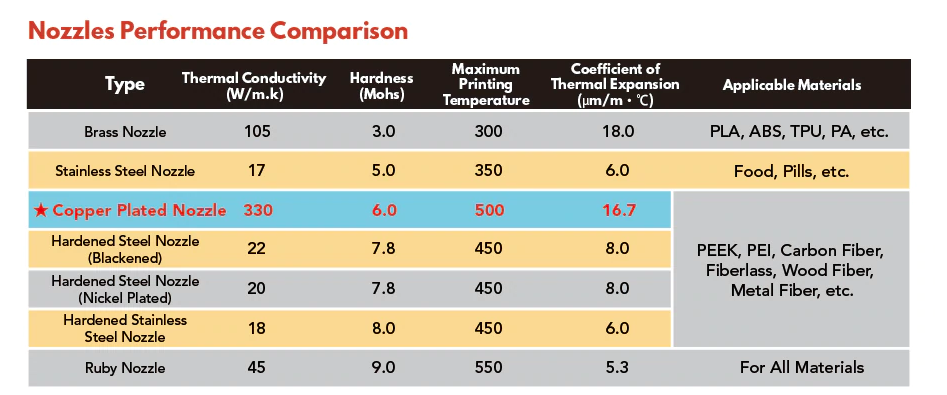

Are stainless steel nozzles prone to clogging easily? What else can I look at to get this printing correctly? I never thought a dual hot-end would be this hard to set up, especially when the printer was printing great with just the one nozzle.

Any help or pointers would be greatly appreciated.

Thanks,

Justin

-

@yagodajm said in Dual Hotend setup:

I did swap out the 0.4 nozzles for some 0.6 stainless steel ones (I am not sure if this is part of my problem or not.

that is almost certainly your problem. stainless steel is terrible for heat transfer. you will have to print a way high temperatures with it.

-

-

@Veti Thank you, I thought that was it, but just wanted to make sure. I guess I will get some different ones.

Thanks,

Justin -

i am waiting for my copper plated ones to arrive.

-

@Veti Cool, let me know how they work out. I put .6 brass on and I am still having issues, now I can't even get a first layer to stick. Both of my nozzles touch the bed when I set z 0 and then I run my mesh leveling. I am still trying to figure this dual nozzle thing out. I order a 2 in 1 out mixing one to see if I can get better results.

-

@yagodajm said in Dual Hotend setup:

Both of my nozzles touch the bed when I set z 0 and then I run my mesh leveling.

when you change nozzles you need to measure you z probe offset again.