Translating Duet3d into PrusaSlicer Machine limits

-

Hi,

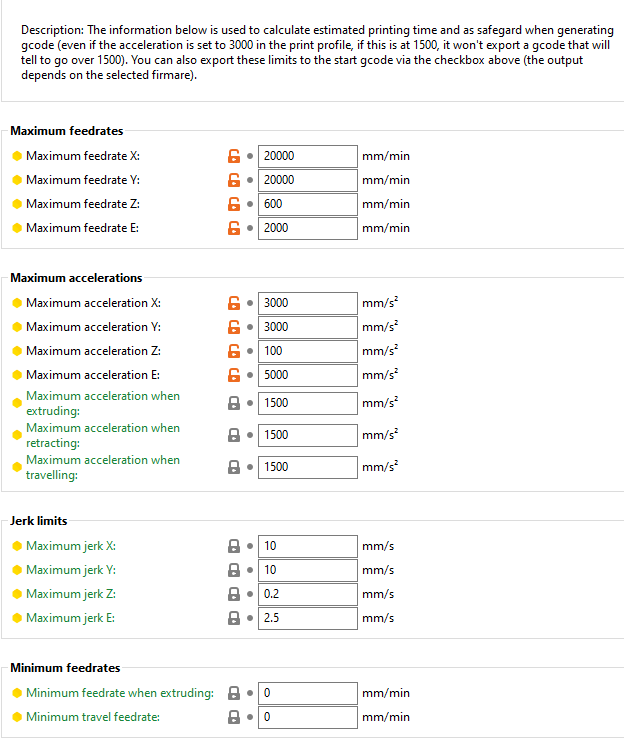

I've started using a fork of PrusaSlicer and I really like it, the infill and ironing settings are brilliant.

In the slicer there is a page to define machine limits. I've mnaged to set a number of them but cant figure out how to calculate jerk.

Can anyone help?

(settings with the orange padlock I have changed)

950 ; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Sep 05 2020 23:57:30 GMT+0100 (British Summer Time) ; General preferences M80 ; Turns on the ATX power supply G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"BLV MGN Cube" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M587 S"your_wifi_name" P"your_password" ; Configure access point. You can delete this line once connected M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z3200.00 E415.5 ; set steps per mm M566 X600.00 Y600.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z600.00 E2000.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Pressure advance ; M572 D0 S0.05 ; Axis Limits M208 X-23 Y0 Z0 S1 ; set axis minima M208 X305 Y332 Z950 S0 ; set axis maxima ; Endstops M564 H0 ; allow jog without homing M574 X1 S1 P"xstop" ; M574 Y2 S1 P"ystop" ; M574 Z1 S1 P"zstop" ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P1 H5 C"^zprobe.in" H5 F250 T9000 R0.5 ; set Z probe type to switch and the dive height + speeds G31 P500 X-2 Y-16.4 Z1.45 ; set Z probe trigger value, offset and trigger height M557 X20:292 Y15:300 P7 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor"T100000 B3950 C0 R4700 A"Bed Temp" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M307 H0 A498.2 C1435.8 D14.9 S1.00 V24.0 B0 ; Set PID for heated bed values M308 S1 P"e0temp" Y"thermistor" T100000 B3950 C0 R4700 A"Hotend Temp" ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S260 ; set temperature limit for heater 1 M307 H1 A516.3 C152.5 D9.6 S1.00 V23.9 B0 ; Set PID for hotend values ; Fans M950 F0 C"fan0" Q100 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F2 C"fan2" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P2 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Screen M575 P1 B57600 S1 -

@nick9one1 said in Translating Duet3d into PrusaSlicer Machine limits:

M566 X600.00 Y600.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

thats jerk

divide by 60 to get mm/s

-

Even better would be to have PrusaSlicer fetch the correct values from the object model. There is already a way to tell PrusaSlicer the IP address of the Duet, for file upload purposes.

-

@nick9one1 said in Translating Duet3d into PrusaSlicer Machine limits:

Hi,

I've started using a fork of PrusaSlicer and I really like it, the infill and ironing settings are brilliant.

In the slicer there is a page to define machine limits. I've mnaged to set a number of them but cant figure out how to calculate jerk.

Can anyone help?

(settings with the orange padlock I have changed)

950 ; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Sep 05 2020 23:57:30 GMT+0100 (British Summer Time) ; General preferences M80 ; Turns on the ATX power supply G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"BLV MGN Cube" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M587 S"your_wifi_name" P"your_password" ; Configure access point. You can delete this line once connected M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z3200.00 E415.5 ; set steps per mm M566 X600.00 Y600.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z600.00 E2000.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Pressure advance ; M572 D0 S0.05 ; Axis Limits M208 X-23 Y0 Z0 S1 ; set axis minima M208 X305 Y332 Z950 S0 ; set axis maxima ; Endstops M564 H0 ; allow jog without homing M574 X1 S1 P"xstop" ; M574 Y2 S1 P"ystop" ; M574 Z1 S1 P"zstop" ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P1 H5 C"^zprobe.in" H5 F250 T9000 R0.5 ; set Z probe type to switch and the dive height + speeds G31 P500 X-2 Y-16.4 Z1.45 ; set Z probe trigger value, offset and trigger height M557 X20:292 Y15:300 P7 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor"T100000 B3950 C0 R4700 A"Bed Temp" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M307 H0 A498.2 C1435.8 D14.9 S1.00 V24.0 B0 ; Set PID for heated bed values M308 S1 P"e0temp" Y"thermistor" T100000 B3950 C0 R4700 A"Hotend Temp" ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S260 ; set temperature limit for heater 1 M307 H1 A516.3 C152.5 D9.6 S1.00 V23.9 B0 ; Set PID for hotend values ; Fans M950 F0 C"fan0" Q100 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F2 C"fan2" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P2 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Screen M575 P1 B57600 S1Where have you find this screen ? in PrusaSlicer 2.2.0 I don't see it

-

You need to be in expert mode and have Marlin selected as the firmware. It doesn't show under RepRap.

-

@Rushmere3D I don't understand why you select Marlin for a Duet, which is RepRap firmware.

Why ? -

You'd have to ask the OP. I was just answering your question.

-

@Rushmere3D said in Translating Duet3d into PrusaSlicer Machine limits:

You need to be in expert mode and have Marlin selected as the firmware. It doesn't show under RepRap.

i think he wants to add it to prusaslicer for reprap.

this will allow prusaslicer to better estimate the required time.