Pulley VS belts

-

Good morning all.

Straps instead of lead screws for guiding the bed (Z) on a CoreXY?

I am thinking about modifying the displacement of my bed on a CoreXY. My idea is to replace the lead screws with a belt system ... The advantage in my opinion is that this system is less strict in alignment and therefore has less friction. However, the flaw is that you may need a pulley system to increase the force and find a solution so that the plate does not come down when the machine is off. Who uses belts on this type of installation?

Thank you

-

there are several printers

voron switchwire (corexz)

voron 2.4

ender 3 mod (i am currently trying this out, just waiting for some parts)

https://www.thingiverse.com/thing:4243512and many more.

-

@Rudy2A Yes, belts won't contribute to Z axis wobble, but don't kid yourself, alignment with belts is still critical- the working side of the belt loop must be kept parallel to the Z axis guide rails.

My printer uses belts to lift the Z axis, and a worm gear reducer on the motor that prevents bed motion when Z axis motor power is cut. It works well.

-

Hi,

I was getting ready to mod my printer with three Z steppers to try out Auto Bed Leveling.

Then I read about someone's printer that used belts for Z.

So my mod included the three steppers (with built-in planetary gearboxes) AND used belts.

Very happy with the results.

Frederick

-

@Veti Thank you for that clarification…

-

@mrehorstdmd said in Pulley VS belts:

Mon imprimante utilise des courroies pour soulever l'axe Z et un réducteur à vis sans fin sur le moteur qui empêche le mouvement du lit lorsque l'alimentation du moteur de l'axe Z est coupée. Ça marche bien.

Do you have an example of your reducer ?

Thank's

-

@fcwilt said in Pulley VS belts:

Très heureux avec les resultats.

Hi Frédéric, This is exactly what I want to do ... I want to put three independent belts each with their own motor (in a triangle position on the bed frame) with the automatic leveling ... Do you have a demonstration of your printer? Thank you

-

@Rudy2A See: https://www.ebay.com/itm/Rino-Motorized-Rotary-Table-Stage-CNC-4th-Axis-Sherline-Milling-Engraver-Router/191714031261?epid=711126295&hash=item2ca30bf69d:g:A7UAAOSwPhdVB2f0

If you drive all the belts with a single motor, you will not need autoleveling because the bed will stay level. If you use multiple motors, you will need auto leveling because you used multiple motors.

My printer uses two belts to lift the bed which is on a 3 point kinematic mount. It never needs releveling unless I take the Z axis apart (last time I did that was >6 months ago).

-

@mrehorstdmd impeccable !!

-

@Rudy2A said in Pulley VS belts:

@mrehorstdmd impeccable !!

While three steppers may be a bit of work it gets the bed level faster and better.

I had one motor driving two lead screws and it took a bit of adjustment of the position of the pulleys on the lead screws to get it level.

And I never got it quite as level as the auto level feature does.

Frederick

-

@Rudy2A said in Pulley VS belts:

@fcwilt said in Pulley VS belts:

Très heureux avec les resultats.

Hi Frédéric, This is exactly what I want to do ... I want to put three independent belts each with their own motor (in a triangle position on the bed frame) with the automatic leveling ... Do you have a demonstration of your printer? Thank you

Hi,

I assume you are talking about a video? I certainly can make up a quick one if you like.

I included an end stop sensor on each Z axis which handles the bed if it is grossly out-of-level.

Then the auto level feature finishes the job.

Frederick

-

@fcwilt said in Pulley VS belts:

Salut,

Je suppose que vous parlez d'une vidéo? Je peux certainement en inventer une rapide si vous le souhaitez.

J'ai inclus un capteur de butée sur chaque axe Z qui gère le lit s'il est grossièrement hors de niveau.

Ensuite, la fonction de mise à niveau automatique termine le travail.

FrédéricIndeed I would like to see the result on video, but I don't want to disturb you! Did you create your printer by taking a model or plan from the internet or did you create it according to your own plans and ideas?

-

@Rudy2A said in Pulley VS belts:

Indeed I would like to see the result on video, but I don't want to disturb you! Did you create your printer by taking a model or plan from the internet or did you create it according to your own plans and ideas?

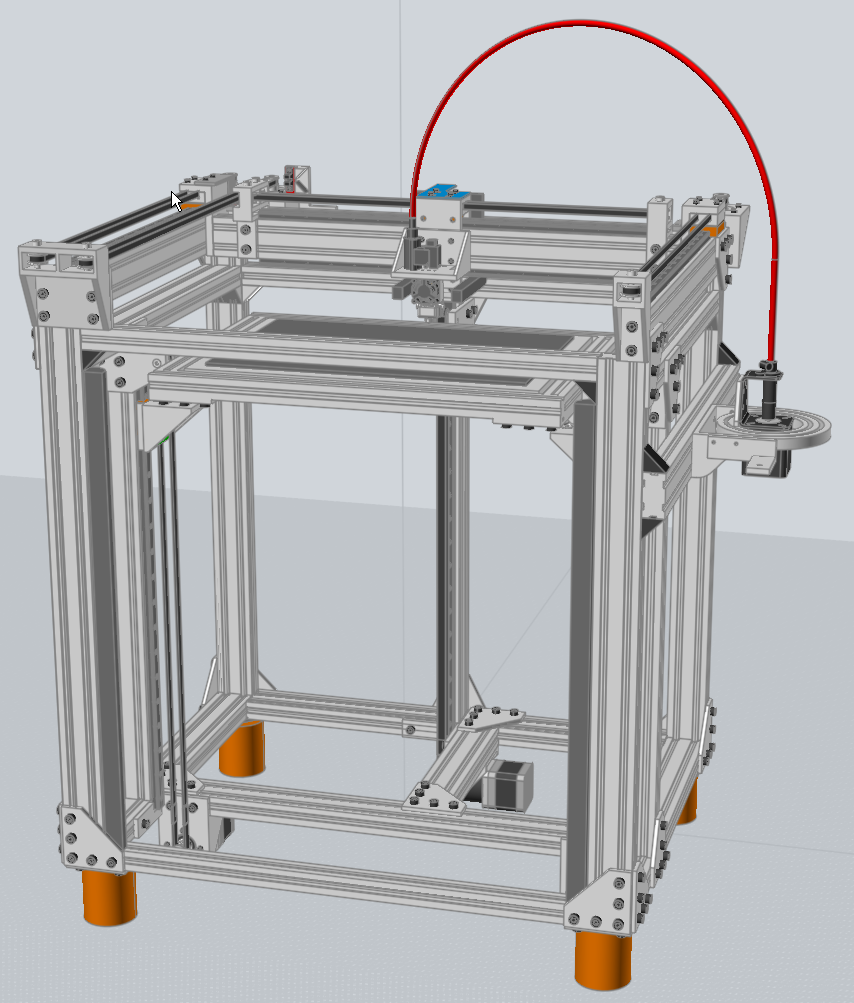

It all started with purchasing the parts needed to build a DBot. I didn't like the initial design and re-worked things a few times.

Then I got the urge to try a MarkForged type printer. I liked that basic design and it hasn't changed much at all.

What has changed is several approaches to the Z axis system.

This is what the current printer is like using the three Z steppers with gearboxes and belt drive.

Once I discarded the initial DBot design everything since it is all my own.

I'm pleased with it but am planning a few changes because the first steppers I purchased appeared to have a 5-to-1 gearbox until you checked the fine print - they are actually 5.18-to-1. But they were inexpensive so I started with them.

I now have the units with the true 5-to-1 gearboxes but am waiting on some pulleys.

Frederick

-

I'll make a video tomorrow (Thursday) and post it here.

Frederick

-

@fcwilt

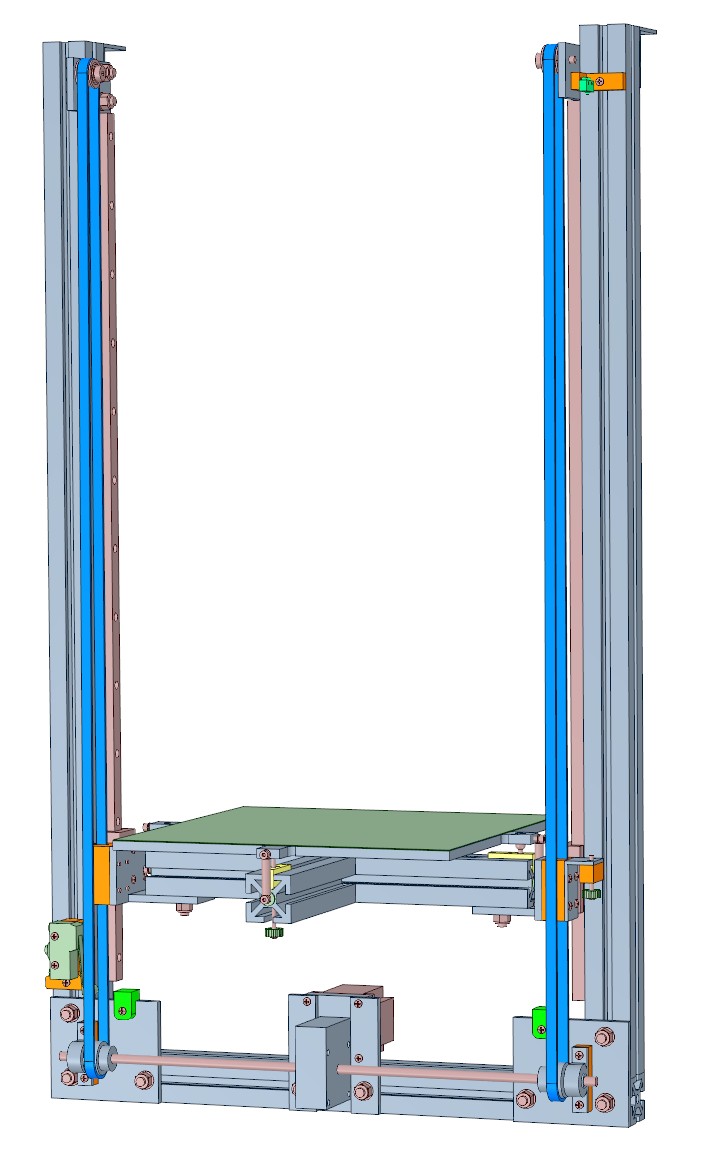

This is my build. uses a belted z axis and linear rails for the z axis. this pic shows rollers, but ive since updated it, and alot of other things. works really well with a planetary gear reducer one a single nema 17 motor.

-

@Turbo said in Pulley VS belts:

@fcwilt

This is my build. uses a belted z axis and linear rails for the z axis. this pic shows rollers, but ive since updated it, and alot of other things. works really well with a planetary gear reducer one a single nema 17 motor.Did some of those parts come from the DBot design?

Frederick

-

@fcwilt referring to the z axis? no not really, besides the bed and its frame. but id be happy to share the cad files if that's something you're looking into. the rest of the build is pretty standard dbot, aside from gantry being dual extruder

-

@Turbo said in Pulley VS belts:

@fcwilt referring to the z axis? no not really, besides the bed and its frame. but id be happy to share the cad files if that's something you're looking into. the rest of the build is pretty standard dbot, aside from gantry being dual extruder

I was referring to the parts supporting the X gantry.

Frederick

-

@fcwilt yes. with some slight modifications that wouldnt change anything. i also have a linear rail compatible version.

-

@fcwilt Thank you. Sounds well thought out!