M106 fan for enclosure heater.

-

I am adding a enclosure heater to my printer.

i want to run a few fans at 100% to circulate the air and to blow over the heater element.its probably a vary simple solution but i can find the answer.

i can't have a thermal controlled fan because the fan needs to turn on with the heater or the chamber will not heat up and the heating element will over heat without air flow.

i don't want an always on fan as i don't plan on using the chamber heater often.

the heater will be running pid so i can't hook the fan to the same output because i always want the fan at full power.

i just want to map a fan to come on full blast when the heater is running and to turn off at the end of the print.

I thought about having the slicer turn on a fan before heating the chamber but if i use the web interface to turn on the heater and forget about the fans i will over heat the element.

-

forgot to mention.

duet2 wifi with duex2 board running firmware 3.1.1 -

Wouldn't adding a thermister to the chamber heater and using a thermostatic controlled fan work?

-

A couple comments:

- you probably don't want the fan circulating a lot of air while the print is running. Unless you're running the chamber temperature at glass transition temperature of the plastic (pretty hot), air movement will cause the kinds of problems you're trying to avoid by heating the chamber.

- chamber temperature is usually pretty slow to respond to control input, so PID isn't ideal or necessary. The plastic you're printing doesn't care about precise control, either. Bang-bang works fine.

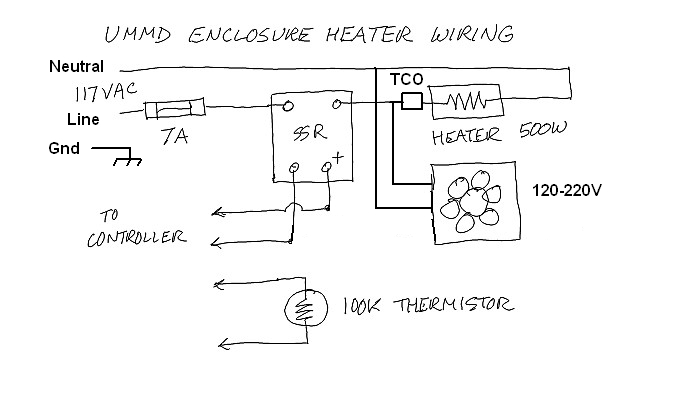

I use a line powered 500W heater switched by an SSR to run the chamber at 50C when printing ABS. A fan is connected in parallel with the heater so that when it has power, the fan also runs. The fan is a 220V unit that I power with 117V. It turns slowly and quietly and moves just enough air to keep the heater from getting too hot without stirring up the air so much that the print starts warping or splitting. It helps that my printer is tall and the heater/fan is at the bottom of the machine while the printing is going on at the top of the machine. The warm air rises by convection so the the heat goes where it's needed without too much help.

-

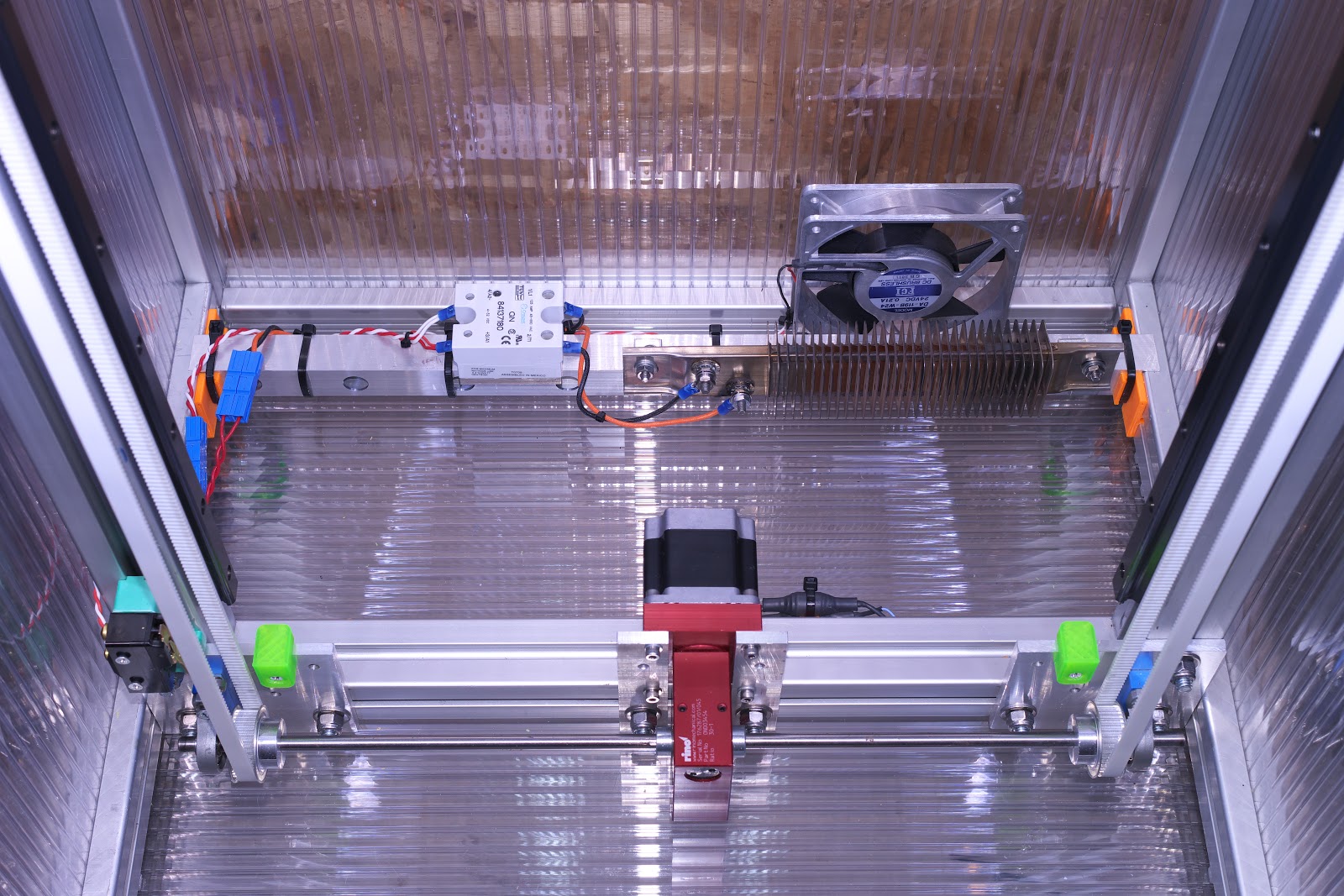

my printer is massive and still vary much a work in progress.

I have a 400w 110v heater with an ssr. the heater has a 12v fan that that needs to be on with the heater so maybe i will switch to bang-bang and run the fan off of the dc side of the ssr.

my next problem is that my print bed is at the bottom of the machine so i might need to blow the hot air down. i'm planning to put fans in the enclosure at the top to blow the heat down the side not directly on the print and use thermostatic control for them when the top of the enclosure heats up.

and probably add a second heater because 400w probably wont be enough.

-

@Jayson The enclosure volume in my printer is 420 liters. It takes the 500W heater about 20 minutes to get the temperature up to 50C. Heat up time depends on the volume you're heating as well as the quality of the insulation in the walls, floor, and ceiling, and probably the mass of metal in the machine's structure, too. My printer isn't particularly well insulated- the entire front side is a single wall of polycarbonate sheet so I can see what's going on in the printer.

-

@mrehorstdmd thanks for the info!

mine is 153liters and has polycarbonate sheets on the sides and top. the bottom is 6.5mm aluminum that is mostly covered with insulation.

so two heaters it is. but I will probably blow a fuse if the bed and chamber are heating at the same time. might have to add a plug in the house and convert the machine from 110v to 220v.i might double wall the sides and top or use something other than polycarbonate to enclose it.

-

@Jayson I specifically kept the chamber heater power down so I could stay on 117VAC. If I start a print from a cold printer, the 20 minute heat up time is not really a problem. First, it's going to take a few minutes for the bed and extruder to heat up. That leaves 15-16 minutes more for chamber heat up. During that time the first few, very-close-to-the-bed print layers are printed. By the time the print has reached a height where the chamber temperature will matter, the chamber has reached the target 50C. I could probably insulate the chamber better and maybe get a bit faster heat up, but I want to come up with something that looks good while it does its job.

When I know I'm going to be printing soon because I'm finishing up a CAD model I'm going to print, I usually preheat the printer, including the chamber, if I'll be printing ABS. Then I go mess with the slicer and generate the gcode, and finally deliver it to the printer. By then everything has warmed up, including the chamber.

-

@mrehorstdmd that's kind of what I had in mind. My bed is not over powerd by any means so it takes a while to get up to temp. That gives the chamber some time to heat up and a 500x500 bed should help heat the enclosure too. I think I will try with the one heater for now and plug the machine into a watt meter to see if I have enough power left for a second heater if needed.