Heat spreader idea? Advice please

-

Hello fellow makers, I'm in the process of rebuilding my delta. Right now it's a Rostock Max with a lot of upgrades and mods, but I want a really stiff and square machine.

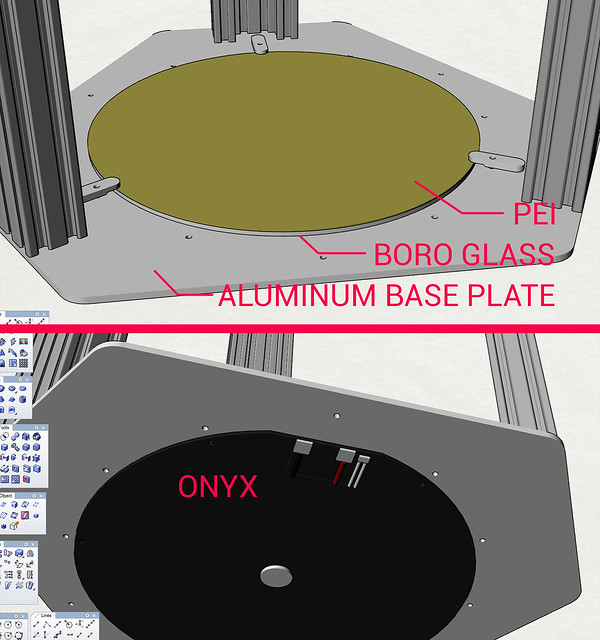

The bottom plate that will hold the 3 extrusions is going to be of milled aluminum, so I thought of using this as a heat spreader.https://c1.staticflickr.com/5/4333/35997018270_bc031d170e_o.jpg

1. PEI Print Surface

2. Borosilicate Glass

3. Aluminum Base Plate (4 or 5mm thick)

4. SeeMeCNC ONYX PCB Heated BedWill this work? or it would dissipate way too much?

I don't know if it has been done before, so any feedback is much appreciated.Martin.

-

Hi,

My gut tells me you are going to lose a lot of heat to the plate and the towers - too much perhaps.

Perhaps you could keep the plate and on top of it put a disc of some insulating material then the other three items, heater, glass and print surface?

On my mini-delta I used a piece of 1/2" MDF (hex shaped) to mount a 3mm aluminum heater (round) and a piece of glass (round).

It seems to be working well.

Frederick

-

I think it would even cause heat expansion of the entire frame, throwing your level out of balance.

-

Hi,

My gut tells me you are going to lose a lot of heat to the plate and the towers - too much perhaps.

Perhaps you could keep the plate and on top of it put a disc of some insulating material then the other three items, heater, glass and print surface?

On my mini-delta I used a piece of 1/2" MDF (hex shaped) to mount a 3mm aluminum heater (round) and a piece of glass (round).

It seems to be working well.

Frederick

Thank you my good sir for the quick reply, that's what I feared.

Indeed, I have it that way atm. Pei - glass - alum spreader - onyx - mdf base plate. A nice working sandwich.My common sense told me this wouldn't work, but I was hoping to hear yesss mate, do it! It's awesome! Some friend have it that way

I think it would even cause heat expansion of the entire frame, throwing your level out of balance.

Good point. I didn't even thought about heat expansion.

Thank you guys for your feedback.

Martin. -

The Tevo Little Monster uses an anodized plate with a machined lip to hold the glass in place with the heater glued to that. That is held in place by some standoffs and M5 bolts. Wouldn't be hard to adapt that idea to the Onyx stack. I like the removable glass on a Max V3 versus the glued in glass on the Tevo.