How precise is Haydn diagonal rods when assembled

-

To measure from the base to the tip of the ball, you could place a dial indicator over a hole drilled to hold the ball stem. Use the indicator to check height differences.

-

I'll bear that in mind. I still do doubt whether it will make any difference, I've got a very accurate printer and at these deviations its noise not data.

-

Good news! But one thing to consider yet. The calibration algo can hide mechanical inaccuracy as it was the case in another thread where calibration results were exelent but corrected rod length was a good amount away from their real length. BTW how many points were used for the calibrations?

-

I use 16 points and 8 factor calibration with my rod length set manually, initially based on actual length, but tweaked to get accurately scaled parts. I have also at another time tested my machine using 64 random points and got the same result as for 16 points.

-

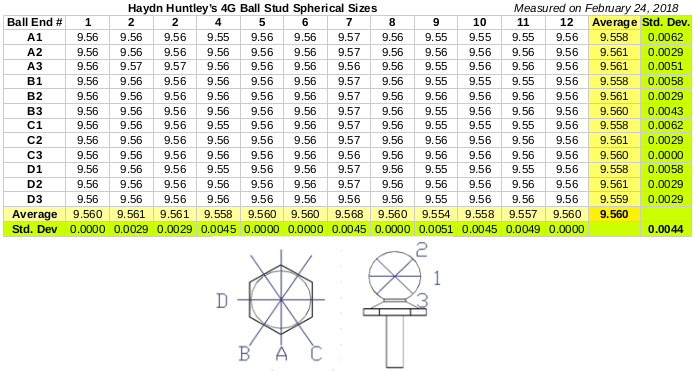

I emailed back and forth with my machine shop in China, and they've created a new batch of ball studs.

These new ones are quite a bit more consistent than the previous ones (roughly 10x better).

Besides the ball being the same size and more spherical, I asked them to make sure they're a consistent height above the hexagonal base, and to make the threading match standard M3 more precisely (the threads used to be a little bit undersized).

Correcting the M3 threading should make these work even better with the M3 holes on the Duet Smart Effector.Here are the results of measuring a random sample this morning:

–Haydn

-

Thanks Haydn!

I have recently purchased an effector with a set of arms, and my biggest issue was the thread diameter. On the old set threads measured anywhere from 2.88 to 2.57(!). Holes in the effector are 2.9, so there was a lot of play. On the new batch, I was able to select balls that were close to 2.9. With a new set, I am able to get to calibration tolerances everyone reporting here. However, I attribute this mostly to using the Smart Effector vs mini IR. I have used TrickLaser arms/effector before, which I believe were pretty good, but not compatible with the Smart Effector.Thanks for your support and continuing improvement of the product!

-

As the topic starter I have just received a very generous offer from Haydn willing to send me a set of ball studs from the new batch free from charge. What's an exceptional service! Many thanks to Haydn for his hard work of improving already excellent design!

-

That's kind of him. I'll email him and buy a couple of sets but as we determined its not likely to make much difference.

-

Thanks Doug that makes sense but I have 360mm arms and 300mm calipers, so what I wondered is whether there is a trick to measure something that is longer than the calipers? I could use the metal rod that protrudes from the caliper, but how to measure to high accuracy like this I don't know.

Just clap a block to the edge of your desk, butt the rod up against it, mark the end, then repeat for each rod, see if all your lines are in the exact same place

-

Thanks, it's an idea sure. In the end I got a local engineering firm who are literally 200 yards from me to measure the rods (with high grade bearings at each end) on their bewildering array of large calipers. They were not significantly different from one another:

350.68

350.66

350.7

350.68

350.7

350.68So I doubt I'd see the difference in the lines if I drew them on the bench, we're talking about a variance of 40 microns. The same with the balls, whilst there was a difference in diameters it was very small. Matching up the rods and balls to achieve 3 pairs of almost exactly equal length yielded no change in calibration or print quality in my otherwise all-metal and very precise kossel XL, compared to the situation I had before where they were all basically random.

But if Haydn has commissioned a new batch of balls that are much more precise, then this matches the rods which are made to very tight tolerances, and marketed as such.