Motor Phase A/B Disconnected on Driver 5

-

New Mainboard 6HC replacing a standard old cartesian FDM board. Before printing I verified every stepper connection and tested individual motor movement and it all seemed fine. During my first calibration print though, the error "Motor Phase A/B disconnected on driver 5" popped up before the 15A fuse triggered. I replaced the fuse and everything seems fine, except the same error is still there when I try to test stepper driver 5 (an extruder motor)

I've tested the original motor and wire on another driver and it works fine. I've tested a different motor of the same model as well as a different connector on driver 5 and get the same error so I have ruled out my motor and wire connector.

As a temporary fix I've just swapped the extruder on stepper driver 5 with the extruder on driver 4. Seems to work just fine, no errors so far.

I suspect the driver 5 might have been damaged during that first print, but I would like to see if there is anything I can test other than hardware just in case I am making some error.

-

My config.g

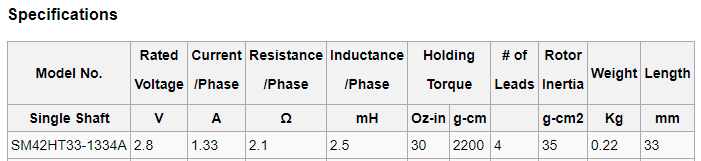

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Mon Jan 25 2021 18:27:38 GMT-0500 (Eastern Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S0 ; physical drive 0.4 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M584 X0.0 Y0.1 Z2:3 E0.4:0.5 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X98.52 Y99 Z1573.00 E49.38:49.38 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z240.00 E1500.00:1500.00 ; set maximum speeds (mm/min) M201 X800.00 Y600.00 Z100.00 E10000.00:10000.00 ; set accelerations (mm/s^2) M906 X1330 Y1680 Z1680 E1330:1330 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X254 Y254 Z254 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io0.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y1 S1 P"!io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S1 P"!io2.in" ; configure active-high endstop for low end on Z via pin io2.in ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp2" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp2 M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set temperature limit for heater 1 to 250C M308 S2 P"temp3" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin temp3 M950 H2 C"out3" T2 ; create nozzle heater output on out3 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S250 ; set temperature limit for heater 2 to 250C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"out6" Q500 ; create fan 2 on pin out6 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"out7" Q500 ; create fan 3 on pin out7 and set its frequency M106 P3 S0 H-1 ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P1 S"Big" D0 H1 F2 ; define tool 0 G10 P1 X0 Y0 Z0 ; set tool 0 axis offsets G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P0 S"Small" D1 H2 F3 ; define tool 1 G10 P0 X59.5 Y0 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memoryExtruder Motor(s) Specifications

M913 and M906 output:

2/15/2021, 4:18:38 PM m913 Motor current % of normal - X:100, Y:100, Z:100, E:100:100 2/15/2021, 4:18:22 PM m906 Motor current (mA) - X:1330, Y:1680, Z:1680, E:1330:1330, idle factor 30% -

I'm surprised the fuse blew as well. Are you sure you don't have a short somewhere?

When and where did you purchase the duet3?

Can you post some clear photos of the board?

-

I tossed the fuse away after putting in a new one, but the internal metal piece was in 2 pieces after the sudden shutdown. If it is a short, it doesn't seem to be in my motor or my connectors since they all work fine on the other drivers.

The board was purchased from Filastruder on 01/19/2021.

Board:

-

the crimp jobs on your motor connectors seem bad.

the end part should hold the outside of the cable.

do you have a proper crimping tool?

-

@Veti I used this: https://www.amazon.com/gp/product/B00004SBDI

This was my first project that required crimping and I followed some random video tutorials. I'll definitely redo all the connectors at some point. The other 5 drivers work just fine and I've swapped around all of the connections though, so it doesn't seem like my poor craftsmanship is the culprit.

-

to agree with @Veti on this one there are a few points where it looks possible from the phot posted that wire pairs on the motors could actually touch on the connector:

It not definitely that that caused the problem, especially if the 15A fuse blew as well as just popping the stepper driver MOSFETs, however I would fix that before powering your motors further.

-

this is the tool for the crimping

https://www.amazon.com/Engineer-PA-21-Universal-Crimping-Pliers/dp/B002L6HJ8W/