Magnetic sensor errors - long print

-

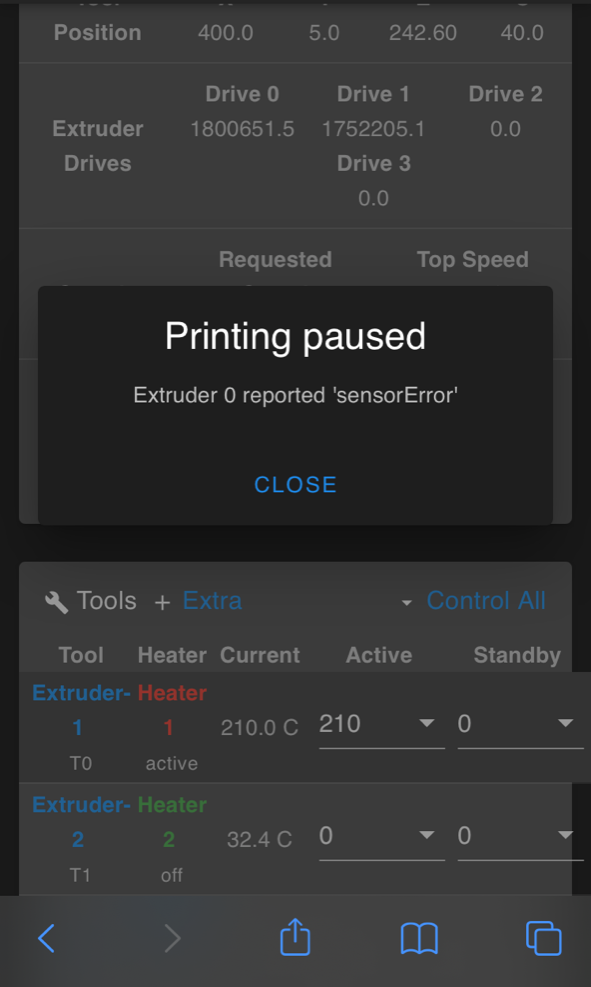

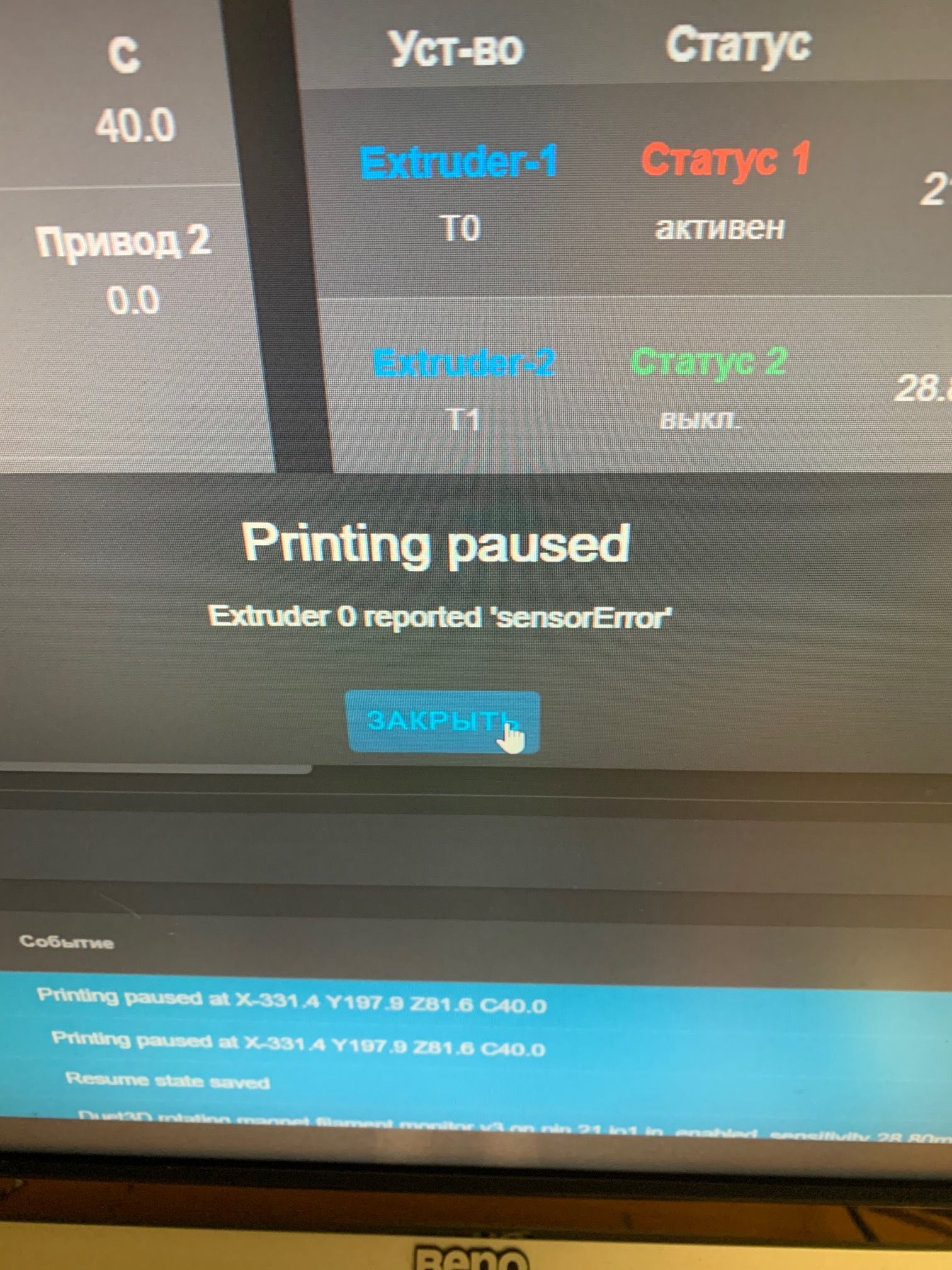

When printing a part about 100 hours long, a "sensor error" appears. Received it already 4 times in 100 hours.

You just need to continue printing and everything works until the next error. I don't see any more messages. The filament monitor is working properly. Except for one more nuance - I have already received the message "tooMuchMovement" 2 times, although it is physically impossible for the feed to be increased.

Well, and another strange thing: for printing, I need about 10 kg of plastic. The slicer shows 3189299.50 mm which roughly corresponds to 10 kg PLA. But in status now: Layer 927 of 1100, Filament Usage: 5827260.0 mm (0.0 mm remaining). This is strange.

Screenshots:

-

The entire extruder including heaters, motor, etc. as well as the filament monitor itself are connected to one Duet 3 Toolboard 1LC (address 21).

-

Can you please provide some more details?

Config.g and the results of M122 and M122 B1 please.

Sample gcode?

-

@Phaedrux said in Magnetic sensor errors - long print:

M122

Of course.

Now I have changed the sensor and start printing for 22 hours.

The printer has a 1mm nozzle, so a lot of plastic goes through the sensor. This print is for 2 kg.

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v1.01 or later (standalone mode) Board ID: 08DJM-956BA-NA3TN-6JTDJ-3S86M-1TBGT Used output buffers: 1 of 40 (40 max) === RTOS === Static ram: 149788 Dynamic ram: 95336 of which 156 recycled Never used RAM 113552, free system stack 126 words Tasks: NETWORK(ready,189) ETHERNET(blocked,110) HEAT(blocked,278) CanReceiv(blocked,801) CanSender(blocked,348) CanClock(blocked,352) TMC(blocked,17) MAIN(running,1141) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:46:41 ago, cause: power up Last software reset at 2021-03-20 16:36, reason: User, GCodes spinning, available RAM 113776, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x04 Aux0 errors 512,512,512 Aux1 errors 0,0,0 MCU temperature: min 24.0, current 47.3, max 47.6 Supply voltage: min 23.9, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.2, current 12.3, max 12.3, under voltage events: 0 Driver 0: position 30000, standstill, reads 5134, writes 27 timeouts 0, SG min/max 0/286 Driver 1: position 76000, standstill, reads 5138, writes 23 timeouts 0, SG min/max 0/334 Driver 2: position 139400, standstill, reads 5139, writes 23 timeouts 0, SG min/max 0/342 Driver 3: position 8000, standstill, reads 5139, writes 23 timeouts 0, SG min/max 0/317 Driver 4: position 0, standstill, reads 5139, writes 23 timeouts 0, SG min/max 0/329 Driver 5: position 0, standstill, reads 5135, writes 27 timeouts 0, SG min/max 0/252 Date/time: 2021-03-26 13:32:36 Slowest loop: 141.57ms; fastest: 0.07ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.7ms, write time 84.7ms, max retries 0 === Move === DMs created 125, maxWait 762879ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 99, completed moves 99, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 42], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 5 -1 -1 -1 Heater 0 is on, I-accum = 0.3 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is ready with "M122 " in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 141.52ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 1 of 8 - Ethernet - State: active Error counts: 0 0 0 0 0 Socket states: 5 2 2 2 2 0 0 0 === Filament sensors === Extruder 0: no data received Extruder 2: no data received === CAN === Messages queued 11511, send timeouts 0, received 70289, lost 0, longest wait 2ms for reply type 6031, free buffers 48M122 B1 Diagnostics for board 1: Duet EXP3HC firmware version 3.2.2 (2021-02-12) Bootloader ID: not available Never used RAM 154776, free system stack 158 words HEAT 92 CanAsync 94 CanRecv 84 TMC 30 MAIN 317 AIN 259 Last reset 00:47:54 ago, cause: software Last software reset data not available Driver 0: position -92000, 200.0 steps/mm, standstill, reads 1707, writes 39 timeouts 0, SG min/max 0/1023 Driver 1: position 610650, 115.0 steps/mm, standstill, reads 1654, writes 95 timeouts 0, SG min/max 0/1023 Driver 2: position 0, 115.0 steps/mm, standstill, reads 1665, writes 87 timeouts 0, SG min/max 0/0 Moves scheduled 33, completed 33, in progress 0, hiccups 0 No step interrupt scheduled VIN: 24.2V, V12: 12.1V MCU temperature: min 40.0C, current 40.2C, max 40.2C Ticks since heat task active 221, ADC conversions started 2874212, completed 2874212, timed out 0 Last sensors broadcast 0x00000000 found 0 224 ticks ago, loop time 0 CAN messages queued 146, send timeouts 0, received 49000, lost 0, free buffers 36; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M575 P1 B57600 S1 ; Comms parameters for PanelDue M564 S1 H1 ; Forbid axis movements when not homed ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; X drive goes back M569 P0.1 S1 ; Z1 drive M569 P0.2 S0 ; Z2 drive M569 P0.3 S1 ; Z3 drive M569 P0.4 S0 ; Z4 drive M569 P0.5 S0 ; Y drive G4 P500 ; Pause for toolboards init M569 P21.0 S1 ; Extruder 1 (T0) M569 P1.1 S0 ; Extruder 1 spool driver M569 P22.0 S1 ; Extruder 2 (T1) M569 P1.2 S0 ; Extruder 2 spool driver M569 P1.0 S1 ; Coupler M584 X0.0 Y0.5 Z0.1:0.2:0.3:0.4 C1.0 ; set Move drive mapping M584 E21.0:1.1:22.0:1.2 ; set Extruder drive mapping ; Axis Limits M208 Z-4:875 C0:500 M208 X-570:570 Y-630:500 ; Define the bed mounting coordinates M671 X-473:473:473:-473 Y730:730:-735:-735 S10 ;Snn Maximum correction allowed for each leadscrew in mm (optional, default 1.0) ; Endstops M574 X1 S1 P"!io1.in" ; configure active-high endstop for high end on X via pin !io1.in M574 Y2 S1 P"!io2.in" ; configure active-high endstop for low end on Y via pin !io2.in M574 Z0 P"nil" ; no endstop on Z M574 C1 S3 ; Stall detect coupler at low end of its range ;Steps per mm = (Motor Steps per Revolution * Driver Microstep) / (Belt Pitch * Pully Number of Teeth) ; X: GT2-20 / Y: HTD3-20 * (48/16) / Z: HTD5-20 * 6 M92 X80 Y160 Z800 C200 ; set steps per mm M92 E420.00:115.00:420.00:115.00 ; set steps per mm M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M350 C16 I1 M566 X420 Y420 Z8 C2 E200:200:200:200 ; Set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z600.00 C10000 E6000.00 ; set maximum speeds (mm/min) M201 X1200.00 Y1200.00 Z100.00 C500 E2500 ; set accelerations (mm/s^2) M204 P250 T1200 ; Travel and print acceleration M906 X1200 Y1600 Z2400 C500 E700:700:700:700 ; set motor currents (mA) and motor idle factor in per cent M913 C50 M906 I30 M913 E100:0:100:0 ; set Working current to Extruders M84 S120 ; Set idle timeout ;Stall Detection M915 C S5 F0 H200 ; Coupler ; Z-Probe M558 K0 P5 B1 C"^io7.in" H5 A5 F120 T9000 ; set Z probe type to switch and the dive height + speeds G31 K0 X0 Y0 Z0 P1000 ; set Z probe trigger value, offset and trigger height M557 X-500:500 Y-500:500 S100 ; define mesh grid ; Calibrate Nozzle Height probe M558 K1 P8 B0 C"^io8.in" H30 F120 T9000 G31 K1 P1000 X0 Y0 Z0 ; ==== Heaters ==== ; Bed M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 ;M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M950 H0 C"out0" T0 Q10 ; Heater --> SSD-Steuerung ;M307 H0 B0 S0.80 ; disable bang-bang mode for the bed heater and set PWM limit ;M307 H0 R0.425 C261.3 D4.03 S0.80 ; Tuned M307 H0 R0.191 C560.9 D3.56 S1.00 V24.1 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Chamber M308 S5 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 5 as thermistor on pin temp1 M950 H5 C"out9" T5 Q10 ; create chamber heater output on temp1 and map it to sensor 5 M307 H5 R1.000 C30.9 D9.18 S1.00 V24.1 ; Tuned M141 H5 ; map chamber to heater 5 M143 H5 S75 ; set temperature limit for heater M950 F5 C"out4" Q500 ; cooling fan M106 P5 S0 H-1 C"Filament FAN" ; Control be trigger2 ;M106 P5 S1 H5 T22:60 ; thermistatic control M950 J8 C"0.io6.in" ; Input 8 for filament Fan M581 T2 P8 S1 R0 ; Invoke trigger 2 when an inactive-to-active edge is detected on input 8 ; Extruder 1 M308 S1 P"21.temp0" Y"thermistor" T100000 B4725 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"21.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 285C ;M307 H1 R3.214 C42.3 D7.77 S0.75 V23.2 ; Tuned ;M307 H1 R0.056 C194.7 D8.90 S1.00 V23.9 ; small block ;M307 H1 R3.358 C190.6 D7.20 S0.60 V23.6 M307 H1 R1.936 C200.6 D7.57 S1.00 V23.6 ; Extruder 2 M308 S2 P"22.temp0" Y"thermistor" T100000 B4725 ; configure sensor 2 as thermistor on pin 122.temp0 M950 H2 C"22.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S285 ; set temperature limit for heater 2 to 285C ;M307 H2 R3.056 C229.5 D7.91 S0.80 V23.3 ; Tuned ;M307 H2 R3.090 C199.8 D7.36 S0.75 V23.3 ;M307 H2 R3.202 C234.301:234.301 D7.52 S0.70 V23.3 B0 I0 ;M307 H2 R3.358 C190.6 D7.20 S0.60 V23.6 M307 H1 R1.936 C200.6 D7.57 S1.00 V23.6 ; *** Fans ; Extruder 1 Fan M950 F0 C"21.out1" Q500 ; Part cooling fan M106 P0 S0 B0.1 H-1 ; Default off. booststart for 0.1s (B0.1); thermostatic control off M950 F1 C"21.out2" Q500 ; Hotend cooling fan M106 P1 S1 H1 T50 ; Default on. thermistatic control on above 50C ; Extruder 2 Fan M950 F2 C"22.out1" Q500 ; Part cooling fan M106 P2 S0 B0.1 H-1 ; Default off. booststart for 0.1s (B0.1); thermostatic control off M950 F3 C"22.out2" Q500 ; Hotend cooling fan M106 P3 S0 H2 T50 ; Default on. thermistatic control on above 50C ; Tools ; Extruder 1 Tool M563 P0 S"Extruder-1" D0:1 H1 F0 M567 P0 E1:1 ; mixing G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C G10 P0 X0 Y76 Z0 ; Reset tool axis offsets ; Extruder 2 Tool M563 P1 S"Extruder-2" D2:3 H2 F2 ; define tool 1 M567 P1 E1:1 ; mixing G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C G10 P1 X0 Y76 Z0 ; Reset tool axis offsets ; Retraction ;M207 S6.5 R0.0 F4800 T4800 Z0.0 M207 S4 R0.0 F3000 T2100 Z0.4 ; M207: Set retract length ; Parameters ; Pn Tool number (optional, supported in RRF 3.01 and later only) ; Snnn positive length to retract, in mm ; Rnnn positive or negative additional length to un-retract, in mm, default zero ; Fnnn retraction feedrate, in mm/min ; Tnnn feedrate for un-retraction if different from retraction, mm/min (RepRapFirmware 1.16 and later only) ; Znnn additional zlift/hop ; Example: M207 S4.0 F2400 Z0.075 ; FEEDRATE CONVERSIONS ; 20mm/s = F1200 ; 100mm/s = F6000 ; 35mm/s = F2100 ; 120mm/s = F7200 ; 50mm/s = F3000 ; 133mm/s = F8000 ; 70mm/s = F4200 ; * ======= tool offsets ======== * ; Set in config-override.g ;G10 P0 X0 Y76 Z-21 ; T0 ;G10 P1 X0 Y76 Z-21 ; T1 ; Filament monitors ; ** Rotating M591 P3 C"21.io1.in" D0 R30:160 S1 M591 P3 C"22.io1.in" D2 R30:160 S1 ; ** Endstops M950 J4 C"!^1.io1.in" ; Input 4 for filament trigger M950 J5 C"!^1.io2.in" ; Input 5 for filament trigger ; Invoke trigger 1 (M25) when an active-to-inactive edge is detected on input 4 and 5 and a file is being printed from SD card M581 T1 P4 S0 R1 M581 T1 P5 S0 R1 ; Miscellaneous M572 D0 S0.02 ; pressure advance T0 M572 D1 S0.02 ; pressure advance T1 ;M572 D2 S0.05 ; pressure advance T2 ;M572 D3 S0.05 ; pressure advance T3 ; Set up the dock indicator switches on the tools. M950 J0 C"!^io3.in" ; GpIn 3 = tool 0 dock switch M950 J1 C"!^io4.in" ; GpIn 4 = tool 1 dock switch ; Z Motors brake M950 P0 C"0.out1" ; Z Motors brake OFF G92 Z0 G91 ; Relative mode M400 ; make sure everything has stopped before we change the motor currents M913 Z100 ; drop motor currents to 20% G1 Z0.05 M400 G4 P1000 ; Pause M42 P0 S1 ; Brake oFF M911 S23.5 R23.8 P"M42 P0 S0" G90 ;M593 F50 ; cancel ringing at 50Hz M376 H20 ; bed compensation taper M501 ; load saved parameters from non-volatile memory ;G29 S1 ; Do not use G29 S1 within config.g, because no Z=0 datum has been established at that point G90 ; !!! absolute positioning