HELP! Duet 2 WiFi Configuration and DWC Upload???

-

Ok. So.

-Everything is now homed, YAY!

-The Z was P2 S2, so that's probably why it was being so weird

-The only other problem is, whenever I turn on my printer, I end up having to home them again each time. Can it save my settings, or can we program it to home on start up? I'm pretty sure it homes itself before each print...but yeah. Or maybe that's how it's supposed to be?*I guess all that's left is fine tuning then, right? and then running whatever mesh compensation is??? Is it necessary, or do I need to install a BL Touch first before I can use that function?

Thanks,

-Carson

-

When the power is off or the motors time out and the current is reduced the position can no longer be guaranteed so the machine must be homed before you can move it again.

No it's not a good idea to home it as soon as power is applied. It may sound convenient but I'm pretty sure the first rule of automation safety is don't make something move suddenly when power is applied. User must initiate movement.

You'll need to setup the bltouch first before you can do mesh compensation or anything like that.

In the meantime you can level and clean the bed and try a test print.

Calibrating the extruder would be a good idea too.

-

Ok, yeah I'll calibrate the extruder and so forth and run a test print. Should I change any settings in Cura or in the config.g when switching from a Bowden setup to a *direct drive (*which I currently have on this one)? And do I change any settings in Cura because I'm on the duet board now?

Thank you so much for all your amazing help! Seriously, words cannot describe how grateful I am for your assistance so far! What can I do to thank you, for real? do you have a Patreon, or can I write a review? Let me know!

Big smiles over here! I'm not completely at the finish line yet but the hard part is over and I can see the checkered flags.

-Carson

-

Real quick. To be clear down for Z axis is Z+, Left for X is X-, and Front for Y is Y-?

Cuz that's what I have it as now.

I think I spoke too soon lol

-I ran a test where I had all 3 homed, then jogged all three to their centers and hit home all and the x and y were going to the wrong corner (left front instead of back right[where the endstops are]) should I go back in config.g and change some S0's to S1's?

-when the extruder head is in close proximity to the back right it seems to find the correct corner just fine when homed, but if I'm far away it crashes into the opposite corner.

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

Real quick. To be clear down for Z axis is Z+, Left for X is X-, and Front for Y is Y-?

Cuz that's what I have it as now.That is correct.

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

-I ran a test where I had all 3 homed, then jogged all three to their centers and hit home all and the x and y were going to the wrong corner (left front instead of back right[where the endstops are]) should I go back in config.g and change some S0's to S1's?

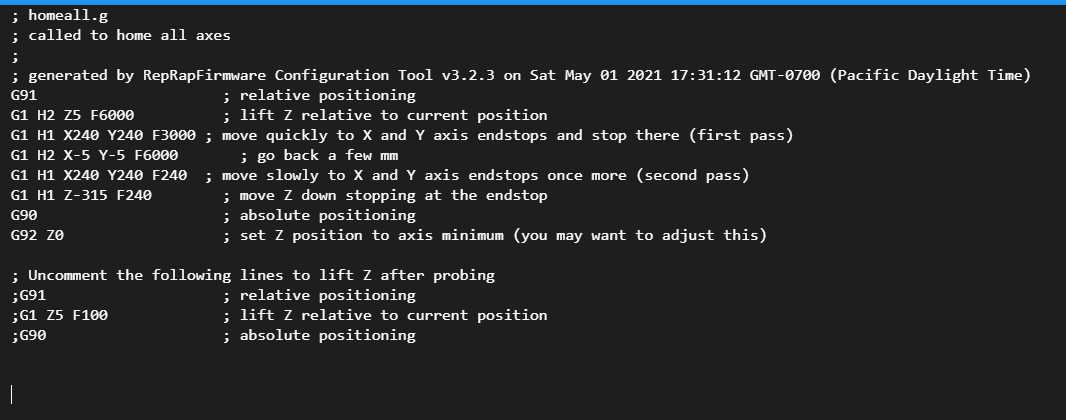

No, you'll need to change the homeall.g file as I posted above.

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X240 Y240 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-5 Y-5 F6000 ; go back a few mm G1 H1 X240 Y240 F240 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-315 F240 ; move Z down stopping at the endstop G90 ; absolute positioningYou changed homex.g and homey.g already?

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X-5 F6000 ; go back a few mm G1 H1 X240 F240 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y240 F3000 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y-5 F6000 ; go back a few mm G1 H1 Y240 F240 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

-when the extruder head is in close proximity to the back right it seems to find the correct corner just fine when homed, but if I'm far away it crashes into the opposite corner.

I'm not sure what you mean by that.

-

Ok, I changed those values and I rechecked each home (x,y,z) individually, and then Home All.

-Everything seems to be working normal now.

-I'll calibrate some things and run a test print.

Thanks,

-Carson

-

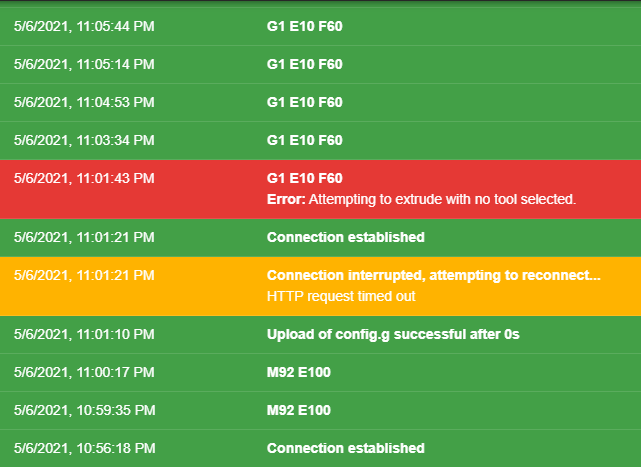

So, I'm trying to calibrate my E-steps, but it seems no matter how slow I try to set it, it goes fast, and no matter what length I set it to extrude, it seems to extrude forever until I eventually have to E stop it, so I don't waste filament .

The guide says to run G1 E100 F60, and 60mm/sec is pretty fast but I ran it anyway. But it says to set it low, so I manually hit 1mm/sec and to extrude 100mm and I got the same results for both...Fast and never ending filament extrusion.

-Not sure what to do

Thanks

-Carson

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

G1 E100 F60, and 60mm/sec

F60 is 60mm/min, so only 1mm/s which is slow.

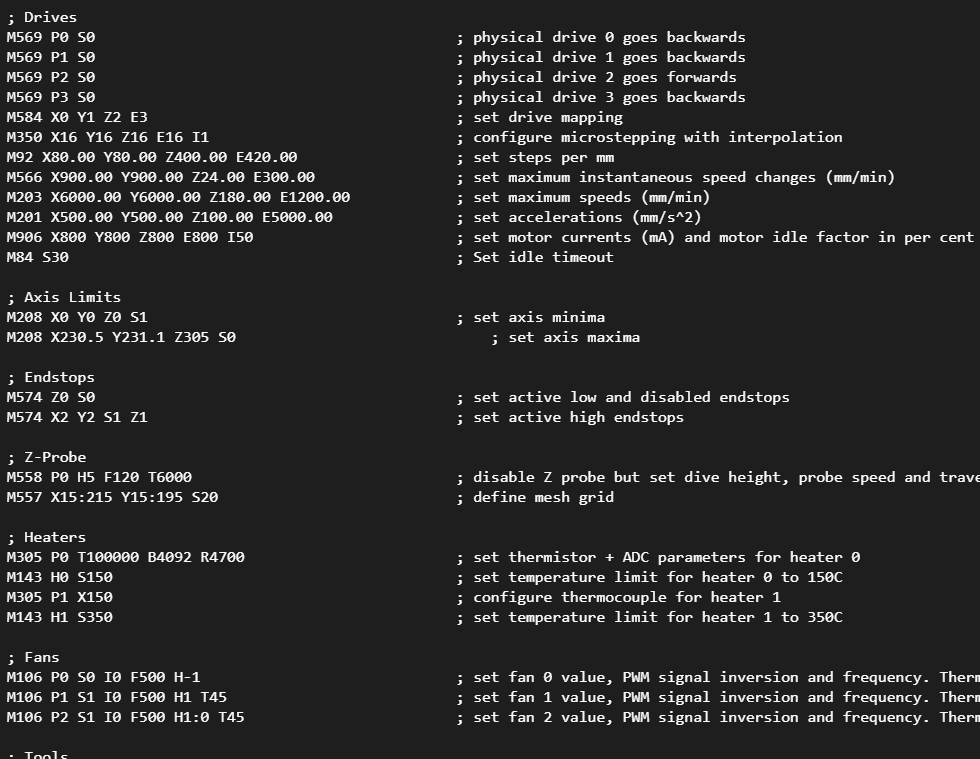

If it's still going very fast it could be that your steps per mm is very wrong from what it should be.

What is the extruder? The default creality bowden setup for the ender5?

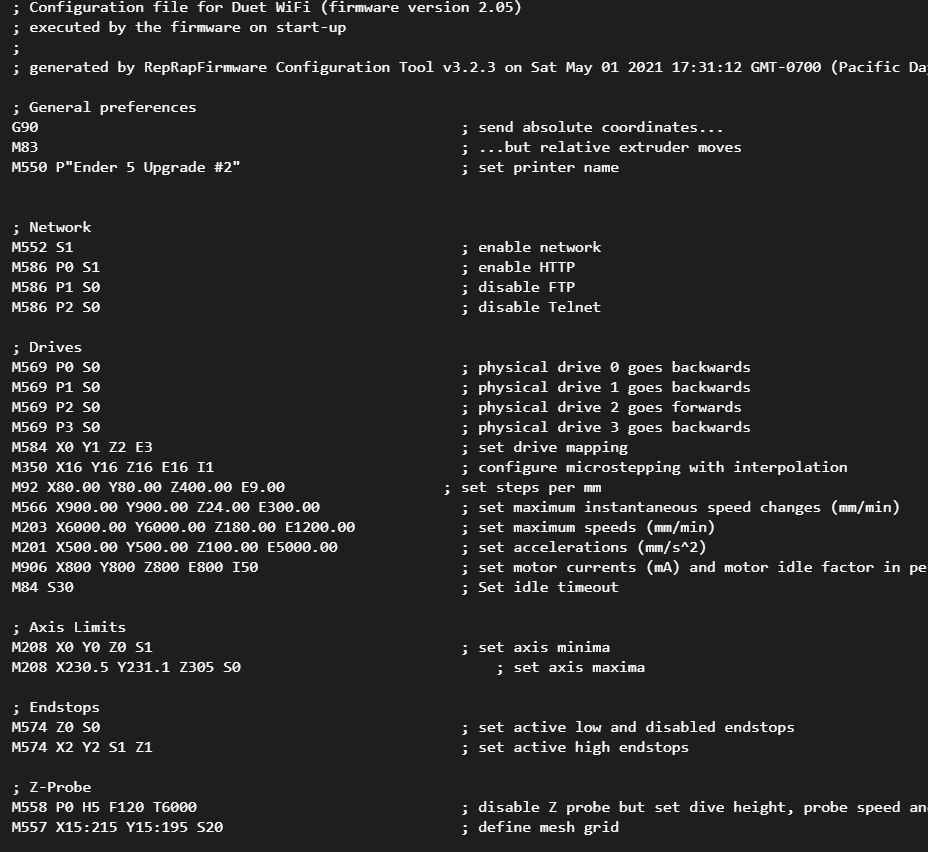

M92 X80.00 Y80.00 Z400.00 E420.00

E420 could be quite wrong if it's teh stock. I think it would be more like E90

-

It's a Micro-Swiss All Metal Hotend Direct Drive.

But yeah it's going really fast. In about 15 sec i had like over 300mm. And it just keeps going and going.

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

It's a Micro-Swiss All Metal Hotend Direct Drive

And what kind of motor on it? 200 or 400 steps per rotation?

Like this?

https://store.micro-swiss.com/products/micro-swiss-direct-drive-extruder

-

Yes, that's the correct one, although it didn't come with a motor so I'm using the Ender 5 stock motor which is 400 (I'm almost positive it's a 400 step motor 99.9%)

Thanks

-Carson

-

Well if it's extruding way too much with 400 steps per mm, try 100 steps per mm. Extrude a small amount to start with to see how it goes.

M92 E100

G1 E10 F60 -

So after changing M92 in the config file, and commanding G1 E10 F60, it is now extruding at a slow speed but I think it's still extruding too much. If I'm understanding the command correctly E=Speed and F= mm of filament to be extruded, correct?

-I ran the command 3 times and got a length of 100mm each time.

-Am I missing something, or is that what was supposed to happen?

Thanks,

-Carson

-

@pcnoobneedsmajorhelp in a G1 command, E is the amount of movement command from the Extruder in mm. F is the feedrate (speed) in mm/min.

Did you reboot after changing the M92 in config.g?

Also, you can just send the M92 command in the console in the web control (e.g. while you're setting it up to find the right value), then update the config when you've found the right value to use.

Edit: the amount of extruder movement is measured in mm of raw filament being fed into the hotend. Of you're commanding 10.. and it's pushing through 100mm, then your M92 value must be 10x too high

-

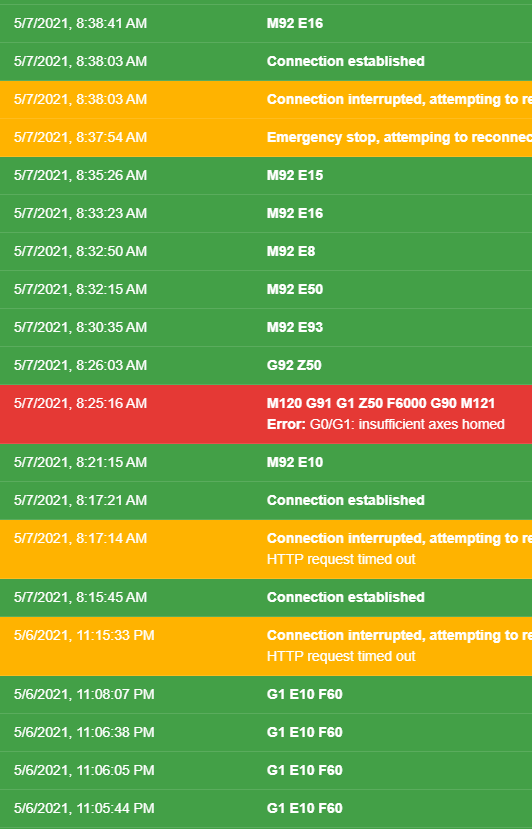

Well that didn't work. I tried it all the way down to 4 and it just keeps going forever. Or not going enough. every time i try it i get a different result. Plus when have you ever hear of a stock ender stepper motor doing lower than 93. Also i noticed that my PanelDue is not in sync with the DWC and it also wont send commands from the PanelDue (unresponsive).

-

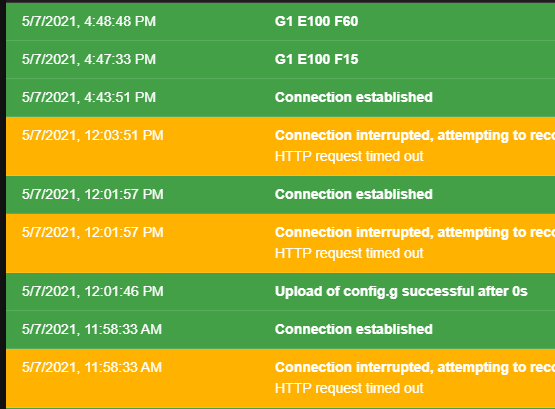

Now the DWC is not responding. And yes I'm connected to WiFi

-

Is it possible you've sent a very long running command causing things to appear unresponsive?

Do things return to normal after a power cycle?

How have you set the steps per mm and what command are you sending for the extruder test?

-

I've cycled the power several times and it still either isn't responsive or is a never ending extrusion. I first had it at 100, then I tried 10, then 4, 14, 15, 8, and lastly 16 and out of all those 8 was the closest at 25mm so I tried 16 to see if I could get close when I set it at 50mm. All the other ones either ran forever or were just way too long. There doesn't seem to be any rhyme or reason to it either. So I have 2 theories. 1: (there are relatives in town using up more bandwidth than usual so..) slow internet connection=lag in responsiveness. Or 2: the motor is broken.

-On the DWC I've commanded E10 F100, E10 F60. After than I manually clicked it to feed 10mm, at a speed of 1, then 5, then 30(which was wayyyy too fast). Then I tried 100mm at 1 and 5. And they don't reflect at all on my PanelDue.

-

Can you post your current config as it is now so we can see what it's setup like?

It's an ungeared extruder, so the steps per mm will be pretty low regardless of the motor.

Have you tried following along with this? https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

-