Magnet filament sensor stopped working

-

@t3p3tony Yes LED worked last time I printed.

When it did not work I ended up with a wild goose chase to find the problem.I will run a print now and decide if I will change it under warrenty.

Last time I had to send it back to get a new one and it took several weeks. I don´t want to be with out it for such a long time -

I writning in this topic since it is a continuation of earlier post.

The sensor with the LED not flashing has worked since I wrote last post (17 of May it seems)

I have not been printing much since June but sensor was working.

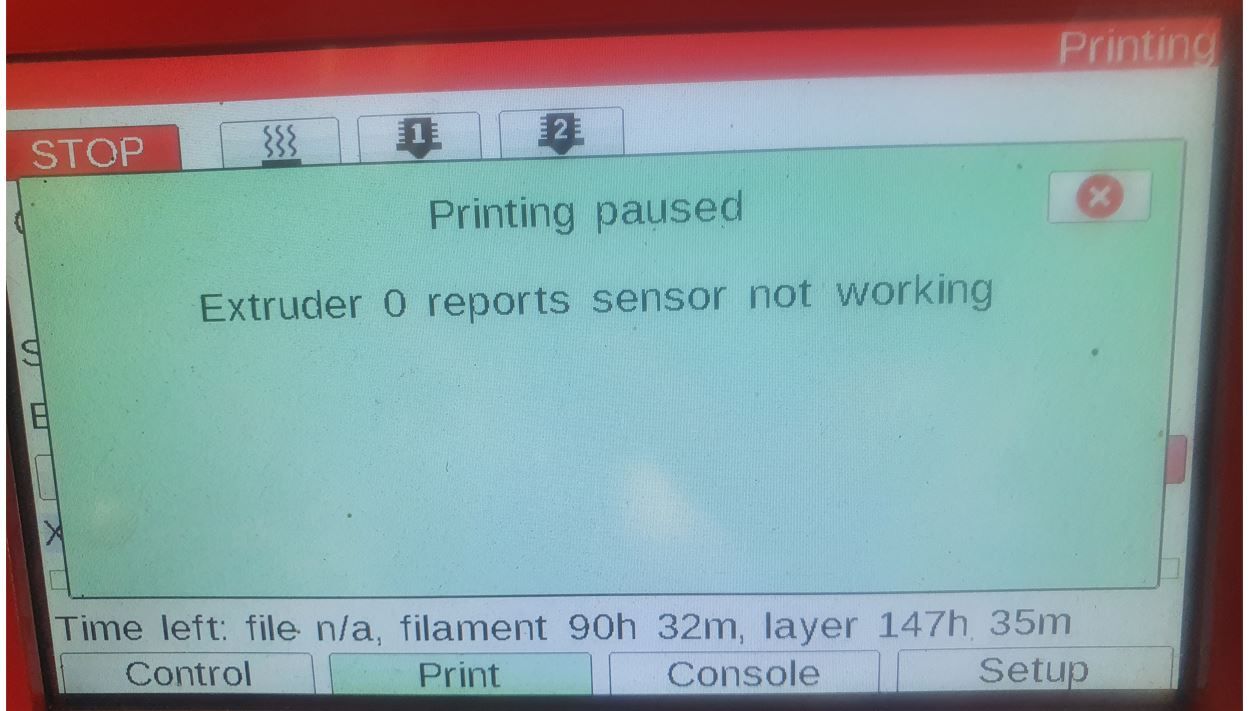

Started a 13 hour print some days ago and got "extruder reports filament sensor not working" about 40 times.

I just resumed print everytime and it keept printing. So the 13 hours turned out being 3 times more.So now I changed the sensor to a brand new one I bought as a spare.

Just tested it and it works but the LED is not working on this brand new one either.

It does have agc 109 out of the box which is really good. But it has a vibrating sound and if I hold it I can fell it vibrating alot.Only tested it for 20 minutes, will start a 54 hour print this afternoon.

So I am asking if the offer to replace the old sensor under warranty still stands.

Also I lke to know if anyone else had this problem.The LED did flash from the beginng so I am pretty sure it is connected correct

Frank

-

@t3p3tony I writning in this topic since it is a continuation of earlier post.

The sensor with the LED not flashing has worked since I wrote last post (17 of May it seems)

I have not been printing much since June but sensor was working.

Started a 13 hour print some days ago and got "extruder reports filament sensor not working" about 40 times.

I just resumed print everytime and it keept printing. So the 13 hours turned out being 3 times more.So now I changed the sensor to a brand new one I bought as a spare.

Just tested it and it works but the LED is not working on this brand new one either.

It does have agc 109 out of the box which is really good. But it has a vibrating sound and if I hold it I can fell it vibrating alot.Only tested it for 20 minutes, will start a 54 hour print this afternoon.

So I am asking if the offer to replace the old sensor under warranty still stands.

Also I lke to know if anyone else had this problem.The LED did flash from the beginng so I am pretty sure it is connected correct

Frank

-

@frankzz agc of 109 is not great. what is the exact error message you get?

-

@t3p3tony For the "old" sensor it was "Extruder D0 reports sensor not working"

May be not exact but to get what it says exactly I need to but the old sensor back.For the new one, it seems to work but the LED is not working at all on this one either.

From memory I thougt AGC 109 was good. Logged on to forum to double check.

Old one had 97 after sanding it. -

EDIT

The housing on the new sensor is much nicer then the earlier ones I have got. It was flat and nice. Sanded it to AGC 104 now. Vibration is gone.

LED still not working.

Starting a long print to test it. -

@frankzz said in Magnet filament sensor stopped working:

LED still not working.

do you mean you get no flashes on the LEDs on the filament monitor at all?

please send the result of M591 D0

-

@t3p3tony Yes, no flashing of the LED what so ever

17:57:09M591 D0

Duet3D magnetic filament monitor with switch on input 3, enabled, sensitivity 25.02mm/rev, allow 10% to 200%, check every 8.0mm, version 3, mag 130 agc 106, measured sensitivity 25.46mm/rev, min 99% max 101% over 582.6mm -

@frankzz ok please email warranty@duet3d.com and we will arrange for a warranty replacement.

-

@t3p3tony

Hi

I have not got around to send faulty sensor yet.

The new one has been working good for 2 months and hundreds of hours of printing.

Two day ago it started with the same problem as the old one.

It says "sensor not working"

Since it has been working for quite sometime I can exclude that it is a wiring problem.

¨

I still like to know what condition is fulfilled to set that message. This so I can figure out what the hell is the problem.

Printer stops between 15 min to 5 hours. It is annoying with a single print of 150 hours taking twice or more as long.

I will send the old faulty sensor ASAP. I need a new one. -

@frankzz said in Magnet filament sensor stopped working:

"sensor not working"

Can you share the entire M591 reply. This sounds like communications between the sensor and the Duet being the issue.

-

@t3p3tony Duet3D magnetic filament monitor with switch on input 3, enabled, sensitivity 25.02mm/rev, allow 10% to 200%, check every 8.0mm, version 3, mag 130 agc 106, measured sensitivity 25.46mm/rev, min 99% max 101% over 582.6mm

I know the AGC is on the limit but the other sensor that have same issue had AGC 87 something so it is not likely it is the problem.

-

@frankzz that issue is not agc related. can you send M591 D0 from DWC console when you get that error.

-

@t3p3tony Sure. Got the error 3 hours ago. Will do it when I get it again.

Not sure what you mean with DWC console.

I type M591 D0 in G code console. But I get nothing different compare when it is working. -

@t3p3tony

Of coarse it took hours before it stopped, This is the longest time it has worked.20:06:06: M24: Printing resumed

20:05:37: M591 D0: Duet3D magnetic filament monitor with switch on input 3, enabled, sensitivity 25.25mm/rev, allow 5% to 300%, check every 12.0mm, version 3, mag 131 agc 108, measured sensitivity 25.59mm/rev, min 33% max 105% over 148837.4mm

20:05:30: : Printing paused at X280.6 Y108.9 Z26.1

20:05:25: : Resume state savedHere is one an hour earlier. NOTE this was NOT because it stopped, I just sent command to check status

19:19:34: M591 D0: Duet3D magnetic filament monitor with switch on input 3, enabled, sensitivity 25.25mm/rev, allow 5% to 300%, check every 12.0mm, version 3, mag 129 agc 105, measured sensitivity 25.58mm/rev, min 33% max 105% over 128101.2mm

19:19:32: M591 D0 -

@frankzz those look different from a sensor error. Makes me wonder if there is something happening with the wiring occasionally.

-

@t3p3tony said in Magnet filament sensor stopped working:

kes me wonder if there is something happening with the wiring occasionally.

I don´t see much difference. What is it you see?

I have changed checked length on this print compared to earlier. Before 8 mm, now 12 mm.

This have made a difference. It has only stopped 3-4 times with the "not working" message during 25 hour print.

The same program got to 30 hours with 8 mm and had over 50 "not working" messages during the same time.

The wiring have no joints so in that case it is the connector.

Remember that this was the same problem I had with old sensor which went away with changing sensor.

It has worked without "not working" message for hundreds of hours of printing.

Sure I can measure wiring but I am 99% sure when I get a new sensor on warranty the problem is gone.

So we can wait for this.My confidence in these sensors is not high. The manufacturer of the printer has just come out with their own sensor and I have ordered these. But until I got these I need the to be resolved

-

@t3p3tony Hi

I think I figured out what triggers the "not working"Printer has 2 printing heads. I mostly only use one but can see temperature on the one not used.

If it is above 57° the filament sensor has issues. Below that it works most of the time. Printed for about 120 hours without "not working" Really thought the problem just went away but got "not working" 2 times within 30 min. Saw the the temp was a few degrees higher. Lower table temp with 5 ° and open lid for a few minutes. Got temp down to 53°. Temp has not been over 57° since and no more "not working"

I know that this temp needs to be under 60° otherwise filament gets soft and stops extruding. So I have been monitoring it for a long time. At least since beginning of summer when I found this issue. When it was 30 ° plus in the workshop the filament roll was warmer than usual and that is when I had a lot of extruder stop with same parameters I had when it was colder. After a lot of trial and error I figured out the temp issue.

It was -15° outside and 12° in the shop 2 weeks ago so I printed with a "curtain" I have in front of the printer to keep the the heat in. I also raised the table temp a few degrees since some prints warped when printed close to the edge of table.

This raised the temp and filament sensor started to have gremlings.Anyway, I finally got the email from Hobby store and sent the other faulty sensor on warranty to them.

When you get that sensor it very well might work when cold. That one had issues during summer if I remember correctly. So it might be a temperature issue.

Also thinking back I pretty sure the issues gets less frequent the further down the tables moves in Z during a print. Temperature gets a few degrees colder round the extruder the further down in Z it is. Had a print that was 550mm high and it worked without stopping the last 150mm.

Since I figured this out I moved the sensor up about 80 mm from extruder. Before it was 10 mm to minimize stretch/compression in the filament.

Now it works better.Once I get a new sensor on warranty and plug it in we will see if LED works. If you look at our conversations about the sensors the LED stopped working on one and when I changed to my spare the LED did not work on that one either.

Sensor still worked so we did not worry about it. I guess the faulty sensor (LED not working) I sent on warranty will find its way to you sometime. It would be good if you check if LED is working.

If it is something is wrong on the motherboard.Frank

-

undefined Frankzz referenced this topic

undefined Frankzz referenced this topic