IDEX printer axis motor sizing question

-

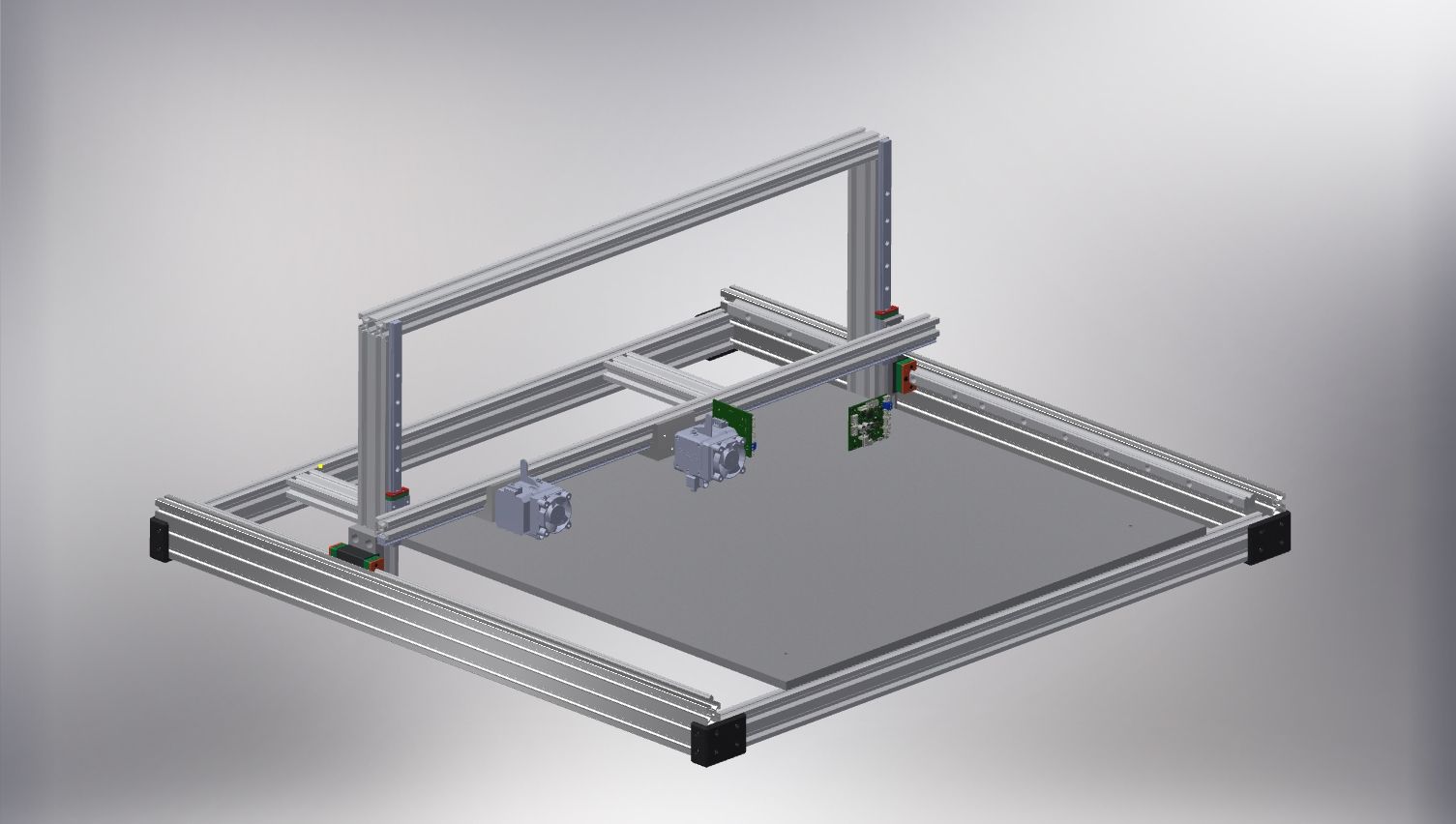

I am building a 600x600x200 idex printer with a moving gantry.

Because the gantry is going to be moving on the Y I am trying to keep the weight down.

I am wondering it a pancake stepper would be able to get the job done.

The moving mass of each extruder if going to be close to 500g all inclusive.

That is a 270g Bondtech LGX FF and a 100g mgn12h carriage and a bit extra for brackets.Specifically I am looking at the LDO 42STH20-1004AS "Super Slim" motor.

I will be running a 16T motor pulley to help the give the motor a little more help.

With all the other mass that I am trying to throw around I would love to use a pair of these small motors to minimize the moving mass.Thanks.

-

For what its worth, I chuck a 5kg bed around with a single nema 17 at ~3k acceleration on a standard bedslinger with a 400x400mm bed. If its really a concern, use two seperate y motors to move the entire gantry.

Otherwise you should be fine.

-

@luke-slaboratory

For moving the gantry itself I do actually have it being moved by 2 separate large steppers.

They are stationary so I don't care about their weight.

But the X axis motors that move the extruders are moving on the gantry so I want to keep their weight to a minimum. -

Right - those X-axis motors are carried by your Y-axis motors, correct? if the Y-axis motors are strong enough and your gantry rigid, going with "big enough" X-axis motors should be more of a concern than saving <5% of the total mass of your Y-gantry, IMHO.

-

@jklaus said in IDEX printer axis motor sizing question:

But the X axis motors that move the extruders are moving on the gantry so I want to keep their weight to a minimum.

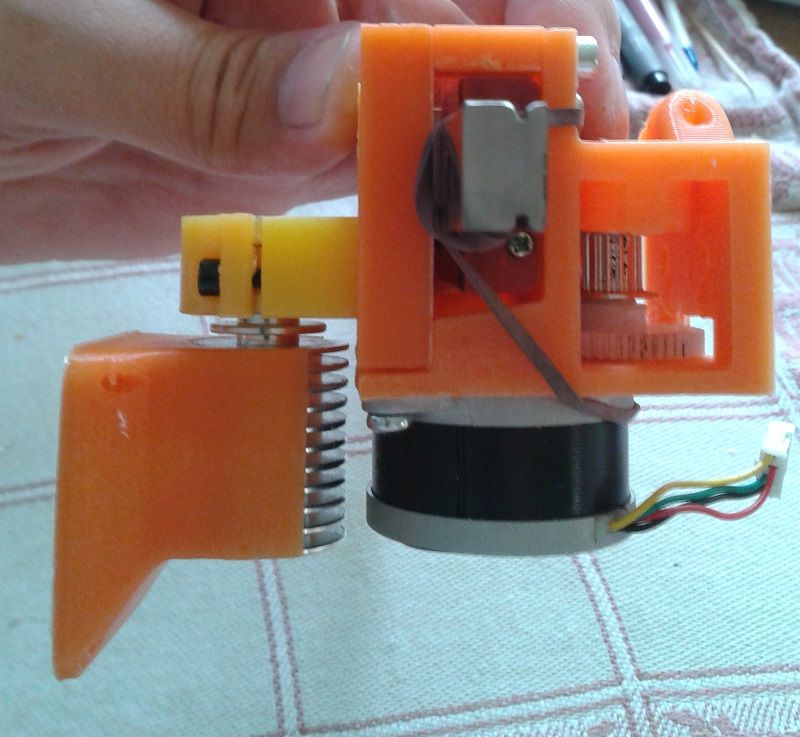

I'm using a similar (slightly stronger) motor on The Hitchhiker. It drives a 16 teeth pulley through a 5:1 spur gear (BMG extruder parts)

I can reach upto 200mm/s speed with reasonable acceleration. Without a reduction gear i wouldn't expect too much.

-

@luke-slaboratory

True, running the numbers in Inventor my whole moving gantry assemble will run right at 11 pounds with everything but the X motors.

The small ones add on about another .6 pounds for both.

While a larger motor with double the torque would be about 1.3 pounds for both.

My Y is driven by 2 motors each with their own driver so throwing around that weight shouldn't be too hard.

And since they aren't moving I always have the option to go even larger on Y if necessary.

My only real concern with the weight is when the Z is getting high I am concerned about possible ringing.

The X axis looks to be 4.4 pounds without motors.

Growing to 5.0 or 5.7 pounds for small or large X motors.

Maybe I am just worrying too much about this and I should go for the large motors.

The connection between the gantry and Y bearing blocks is about as sturdy as I could make it without just being a chunk of aluminum.@o_lampe

That is a pretty interesting setup with a geared moving axis motor.

I haven't seen a setup using a bondtech gear setup to drive an axis before.

That plus something light like an orbiter on top would make a pretty sweet and light direct drive setup. -

@jklaus said in IDEX printer axis motor sizing question:

That plus something light like an orbiter on top would make a pretty sweet and light direct drive setup.

I'm pretty happy with it, although I'd refine the design here and there. ATM I have some backlash in the gears, which causes quality issues.

It works best as 'big nozzle infill extruder'.RRF doesn't have backlash correction for moving axes and I'm also waiting for a way to add an independent mini-Z-axis for mesh leveling.

(hence the dovetail slider)