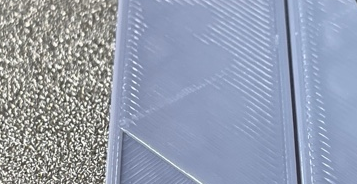

Nozzle skipping across part

-

I realize that this isn't related to Duet products, but there is so much knowledge here, I'm guessing someone will know how/why this is happening. In the pic below, the nozzle left a pale scratch mark as it moved away from the left edge at an approximate +45 degree angle. It's almost as if the move is happening at a nozzle height of 0.000mm. The question is: why.

If the nozzle-to-bed offset was wrong, since Z movements are relative... I think, it wouldn't matter in that respect. Vertical wall quality appears fine, so it seems like the Z bed is moving correctly.

It could be the slicer (PrusaSlicer) not stepping the Z axis sufficiently before the move started. That's hard to believe since it's so widely used; I'd expect complaints would be very vocal if that were the case.

It could be that the PLA+ material expands after it's laid down, which does not make much sense.

Any ideas?

-

That's likely just the slicer doing a move from one place to the next.

There may be a setting that will raise the nozzle a bit before such moves.

There may be an "ironing" feature which is used on the top layers to try and smooth the surface.

But I have never tried either feature.

Frederick

-

It looks like you have a bit of over extrusion as well. The little ridges between extrusion paths is the give away. If you reduce the flow rate ~5% that might get rid of the ridges and also solve the nozzle marks on the top layer without having to resort to Z hop.

-

@phaedrux Okay, thanks, I'll experiment with that. I'm so new to 3D printers that I have little experience to lean on as for what "best" or "acceptable" is.

-

@kb58 If you haven't seen or used this guide on basic calibration yet it's a good starting point. A level bed and proper flow rate is the foundation of a good print.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40