Offsets! Best practices?

-

I have one oddball printer where the bed is smaller than the rest and needs about 7.5mm from the limit switch inwards on the X and 4.5mm in on the Y. What would be the best way to apply this? Currently, after homing I am moving the X Y Z over to the zero corner of the bed and then calling

G92 X0 Y0 Z0and this works well but my bed mesh seems to be out of place ever so slightly. Ive tried tool offsets too in my config.g but it doesn't seem to have any effect after calling G1 X0 Y0.;--------------------------------------- ; Tools ;--------------------------------------- M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X-7.5 Y-4.5 Z0 L2 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C -

-

@dc42 Ah, I never thought to change M208 offsets. I currently have them set for zero off the limit switches. Ill give it a try, thanks!

-

@dc42 Ok, Ive gone through and reconfigured the axis limits and the bed mesh seems to be in the correct place now but.. lets say, if someone was to slice a file that goes outside zero X or Y into the allowable negative margin, the printer will print off the bed. How can I set the limits to not allow this to happen? Could I call

M208 X0 Y0 S0the last line of my homeall.g file or will this skew my mesh leveling grid orgin? -

@LeckieTech That might work. Setting where the axis minima/maxima are doesn't change where 0,0 is, it just changes where the printer sets its coordinates to when it hits the endstop during a homing move. You would however have to be careful about the second time you homed the printer after booting (as it now thinks the endstops are somewhere else!). If I'm honest, if you want to go down that road for some reason, then the G92 method you used originally is probably the way I'd choose

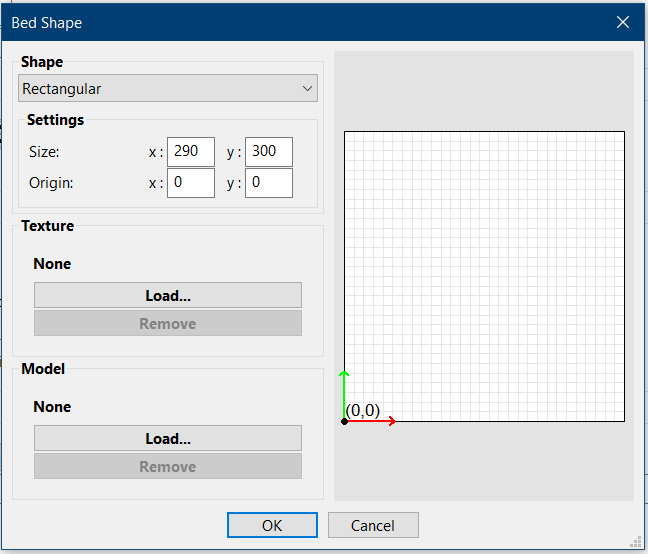

Alternatively you could just live with it and set your printer definition up properly in your slicer. You can set where the origin (0,0) is and the maxima and minima you want it to travel to, then it should give an error message if it has to go outside this area (e.g. off the bed) to print a part. This is how I've set mine up using PrusaSlicer:

There might be times when you might validly want to move the print head off the bed, e.g. if you have a nozzle wipe brush, or when doing mesh leveling/probing with an offset probe like a BLtouch etc. Unless you can't safely get to x = -7.5mm in all y positions, I'd probably just leave it

-

@engikeneer Good suggestions. We use S3D and print many items with large chamfers or fillets. The bed size is set correctly but without isometric views, a small issue with S3D, small amounts could end off the bed. Especially with the number of printers we run here we slice 200 files a day most days. Just trying to prevent a bird's nest.