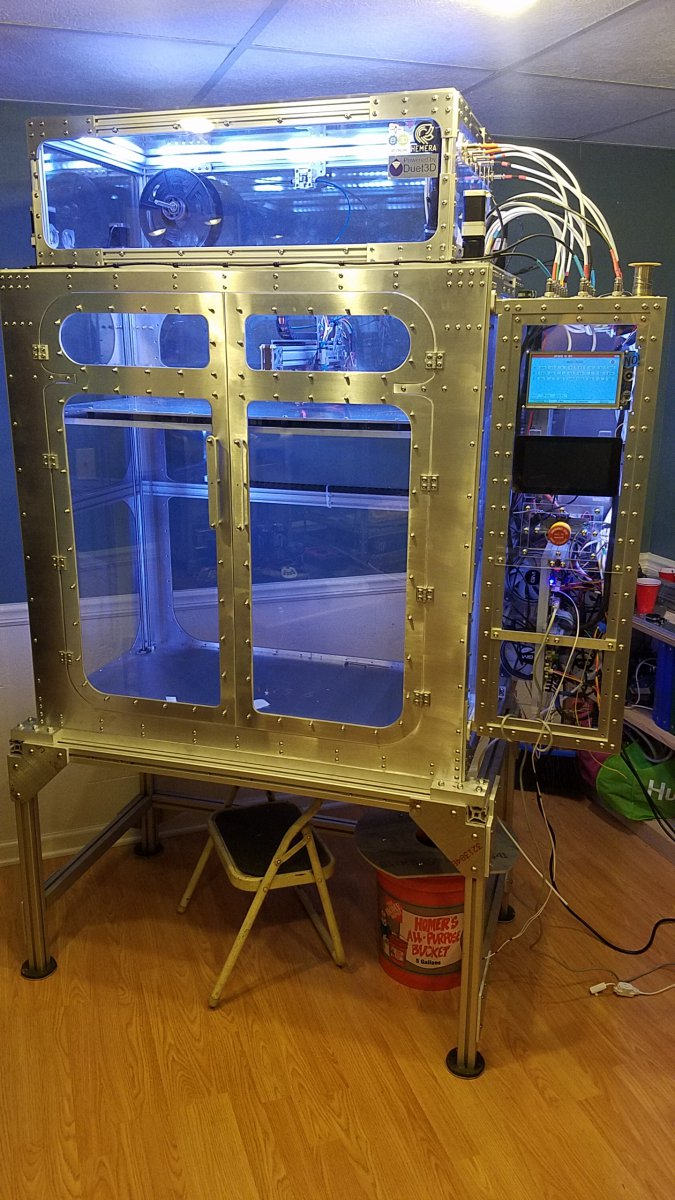

JAWS N 3D

-

Finally have 98% of this thing sorted out. I've done my damnedest to make sure I haven't had to ask any stupid questions......

..... like how the hell I ended up with bed one and bed two with the hot end thermistor tied to bed number two.....weird.

Most of what I've dealt with are errors with converting my stuff to 3.0 + from 2.03.Anyways figure you all might want to see our "bigger boat"

We are using it to make parts for our Oldsmobile.Duet2/duex5, now with 3.3 on it and the paneldue....n some other stuffs.

I drew out and waterjet it...and a bunch of more minimalist brackets etc that it has 2 smaller brothers.

This is a little older video but it gives you a good view of all the important stuff.

https://youtu.be/Ua9t-zh2tIw

-

-

@fcwilt 40:1 planetaries on the 4 z steppers to prevent power off drift

Regards, James -

@fcwilt 40:1 planetaries on the 4 z steppers to prevent power off drift

Regards, James40:1? wow.

Here is a video of my first (and currently only) printer using belt drive for Z.

The planetary gearboxes are only 5:1 but that is enough to hold the bed in place.

Frederick

-

@fcwilt our cold bed is 1/2inch 6061 plate with the hotbed above it being 1/4inch plate....pretty heavy bugger.

Mesh is slow but it shouldn't need to be probed often

-

-

-

@fcwilt 8mm/rev 1000mm

That was actually filmed with the old hundred to one gear boxes which was us ordering without looking at the selected option box....doh'

What drove us insane was trying to get the ft6 to work.... with a bad board and bad bearings and other various defects. It's what led me to design my own.... I'm pretty sure it's a fairly common story among us lunatics

-

@fcwilt 8mm/rev 1000mm

That was actually filmed with the old hundred to one gear boxes which was us ordering without looking at the selected option box....doh'

What drove us insane was trying to get the ft6 to work.... with a bad board and bad bearings and other various defects. It's what led me to design my own.... I'm pretty sure it's a fairly common story among us lunatics

Just FYI if you use lead screws with 2mm lead you might not need such high ratio geared steppers.

Before I switched to belts I used lead screws and found that 2mm lead was good at holding position when power was off.

Frederick