3.4.0 b3 leaning prints

-

I have seen this a couple of times too. There is a 4 degree lean in the - y direction, with the print otherwise very good. The shift is 0.0143mm per layer. Stand alone duet 2wifi, kossal style delta.

-

@adrian52 @CabalSoul @Adrian52 unfortunately I have not yet been able to reproduce this on my Duet WiFi-driven delta printer. Please can you all share sample GCode files that demonstrate the problem. The simpler the print, the better.

-

@dc42 I'm having this problem as well, I think I also had it in the beta 2.

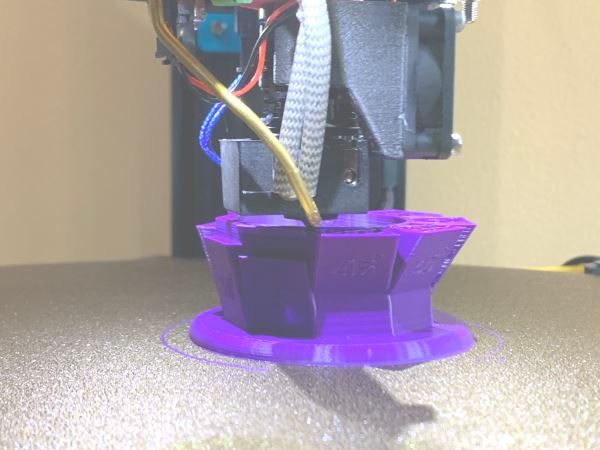

This is a print I'm done today, it's clearly leaning on the -Y direction.

My config: Duet 2 Wifi, Smart Effector and .9 steppers.

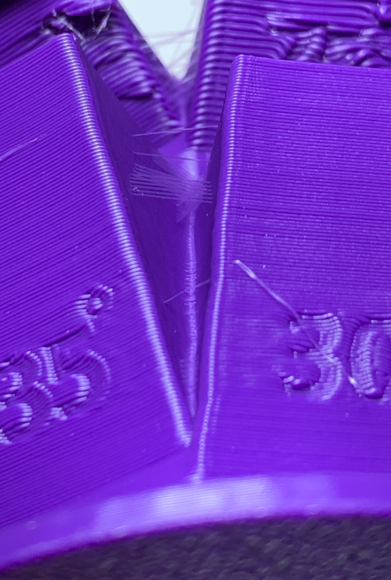

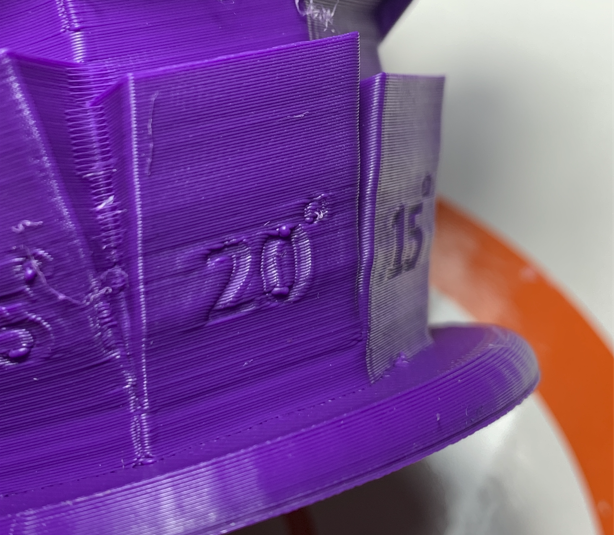

I noticed something interesting on this print, it seems that the "leaning" varies (ie. not constant), I'm wondering if this could be related to the movements that might increase/decrease the leaning.

The edges are not straight and surfaces are not flat on these pictures

Below is my config files and the gcode file I used

leaning print-config.zip.txt

I will try to re-create the issue with a simpler model. -

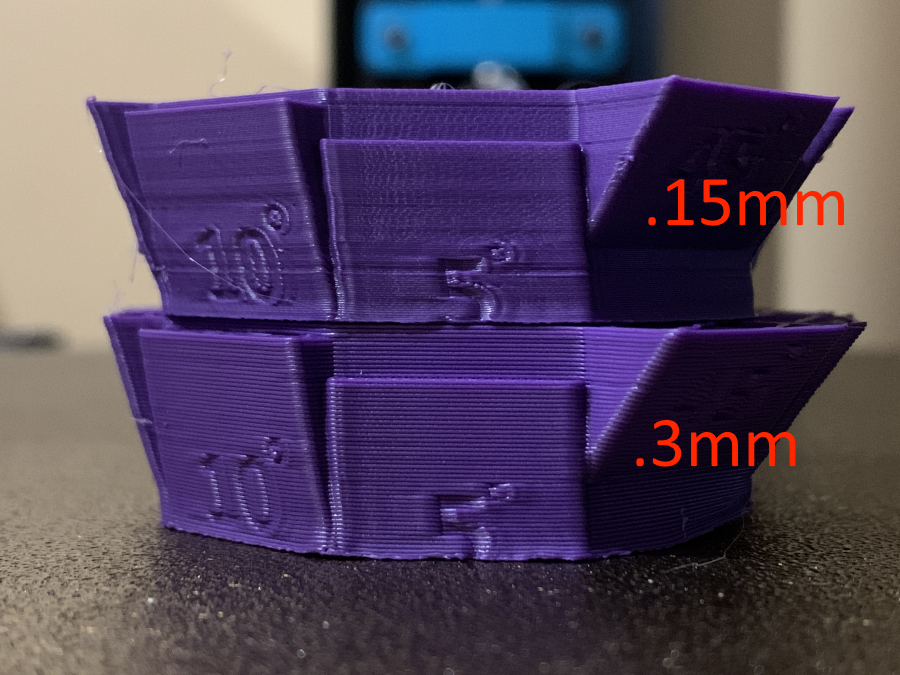

Just did a quick test, same piece printed at .3 and .15mm layer height.

The .15 is leaning more than the .3

It's more obvious than on the picture.The 2 gcode files are in the zip file below

test-gcode.zip.txtI hope that's useful to help with the troubleshooting.

-

@fred-y thanks. Can you also post your config and any other macros that are related.

-

@davea said in 3.4.0 b3 leaning prints:

I printed the same .stl on my old Folgertech cartesian with a Duet Maestro and 3.4 B3 and it printed just fine.

Please share the config.g for both those machines if you can. Trying to pinpoint what is different..

-

@t3p3tony the config is in the zip file below

Pred-config.zip.txt

It should not have any macros.Let me know if you would any testing done.

-

@fred-y can you try with a simple hollow cube and see if that is reproducible. The complex prints take ages to test.

-

When I’m back home I’ll also post the gcode and configs.

But like Id like to emphasize again that the same gcode produces flawless prints on 3.3 and crooked ones on 3.4b3. And they were all „ hollow cubes“

I’ve even used Cura Arachne and Prusa slicer and I had the same issue with both. -

@t3p3tony I think it might be related to y direction travel between objects. With two simple 20x20x20 cubes displaced 40mm in the y direction but aligned in the x direction, I get a pronounced (18deg) slope in the - y direction on both cubes . Printing the same two cubes aligned in y but displaced in x seems to give straight sides.

-

@cabalsoul yes I understand that. I don't think its the gcode itself that is the issue (or even your config). Just need to be able to replicate the issue in order to help @dc42 work out what's causing it!

-

@adrian52 the theory I am working on would make it sensitive to the start and end points of the move, the acceleration, the requested top speed, and the input shaping. A cube with infill has a variety of moves with different start and end points, so would make leaning more likely. A hollow cube does the same XY moves over and over again, so you would be less likely to hit a problematic move, but you might hit one if you shift the cube.

Unfortunately, the rod length, delta radius and steps/mm are also likely to affect whether a move is problematic or not.

If you have a simple print that reproduces the problem readily, it would be helpful to me if you can test which of the following changes makes the problem occur or go away:

- Changing acceleration

- Changing requested speed

- If you are using input shaping, turn it off or change the frequency.

-

@adrian52 ok thanks. I will try and do the same. are your test cubes hollow or with infil? are you using input shaping?

-

@t3p3tony I used 10% gyroid infill, and ei3 input shaping

-

@dc42 I have some more to add to the theory

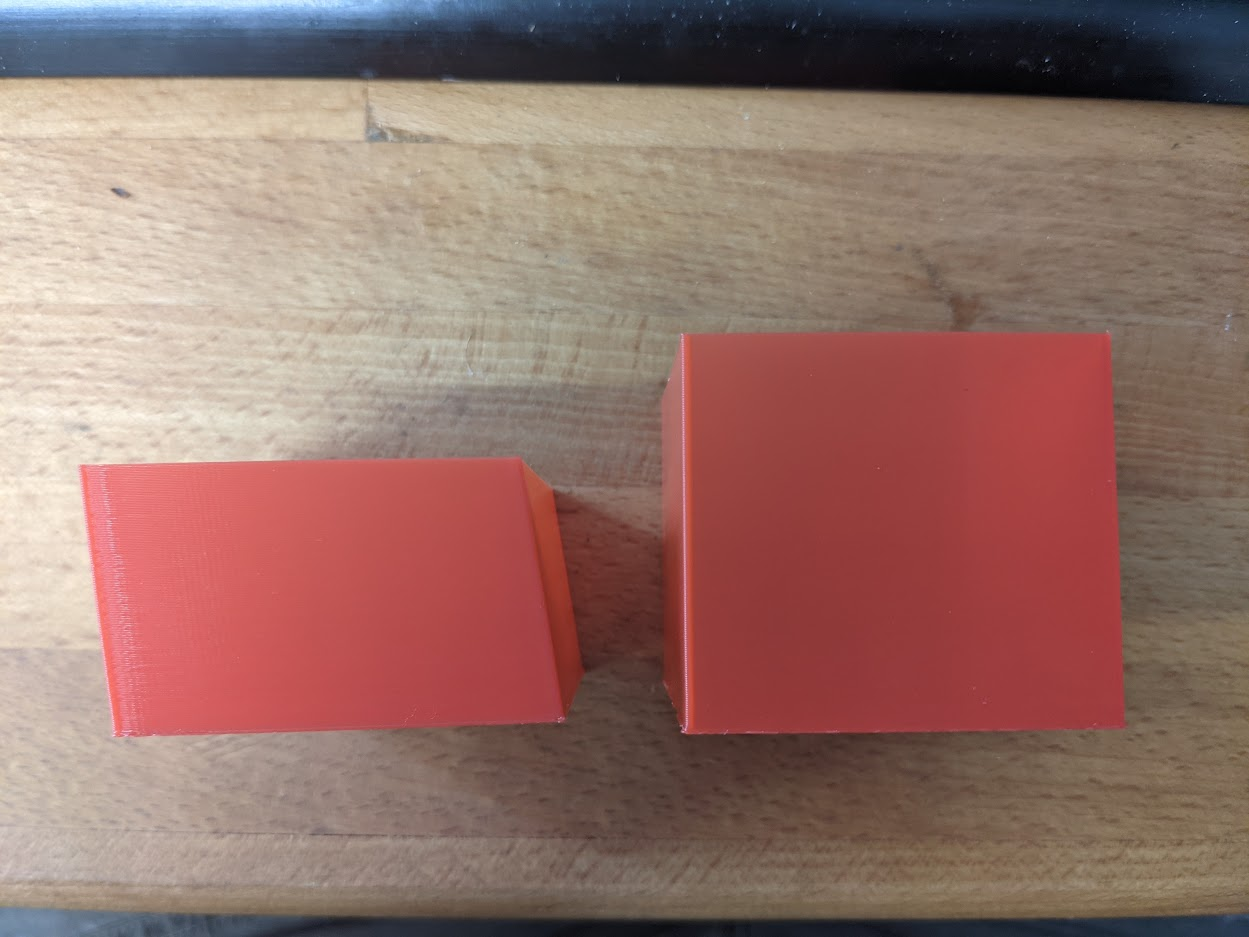

Both cubes are printed with 3.4b3.

The right hollow cube is printed in vase mode.

The left hollow cube was printed as a single wall. This one had a z hop setting of 1mm

I am currently printing the same gcode with no z hop and it is not exhibiting the same leaning in Y.

here is my config; Configuration file for Fly-E3-Pro (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.1-LPC+17 on Wed Jun 30 2021 09:24:28 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Predator" ; set printer name M665 R227 L450 B185 H400 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards using TMC2209 driver timings M569 P1 S1 ; physical drive 1 goes forwards using TMC2209 driver timings M569 P2 S1 ; physical drive 2 goes forwards using TMC2209 driver timings M569 P3 S1 ; physical drive 3 goes forwards using TMC2209 driver timings M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z160.00 E415.00 ; set steps per mm M566 X500.00 Y500.00 Z500.00 E1000.00 ; set maximum instantaneous speed changes (mm/min) next try 3000 M203 X9000.00 Y9000.00 Z9000.00 E10000.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E3000.00 ; set accelerations (mm/s^2) next try 6000 M906 X1344 Y1344 Z1344 E560 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"e1stop" ; configure active-high endstop for high end on X via pin e1stop M574 Y2 S1 P"pson" ; configure active-high endstop for high end on Y via pin pson M574 Z2 S1 P"e0stop" ; configure active-high endstop for high end on Z via pin e0stop ; Z-Probe M558 P8 C"probe" H5 R0.4 F1200 T6000 A9 ; set Z probe type to switch and the dive height + speeds G31 P100 X0 Y0 Z-0.1 ; set Z probe trigger value, offset and trigger height M557 R180 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"boardtemp" Y"thermistor" T100000 B4092 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M207 S4.0 F2400 Z1 M572 D0 S0.4 M955 P0 C"B.1+E.8" I50 ; Miscellaneous M501 T0 ; select first toolI should add that I am using no form of input shaping but I am using PA

-

@jay_s_uk that's interesting! Is the Z hop configured using M207 and firmware retraction, or in the slicer?

-

@dc42 using M207.

The gcode files are the same.

I changed it to 0 using M207 from the console and checked it to ensure it had changed -

@jay_s_uk thanks. Please share the GCode, and I will try it on my delta with Z hop this afternoon.

-

-

@t3p3tony have now tried the two cubes without infill, without input shaping, with z hop=0, and with pa=0, and the slope in the - y direction is the same.