Display and control dual extruder issue

-

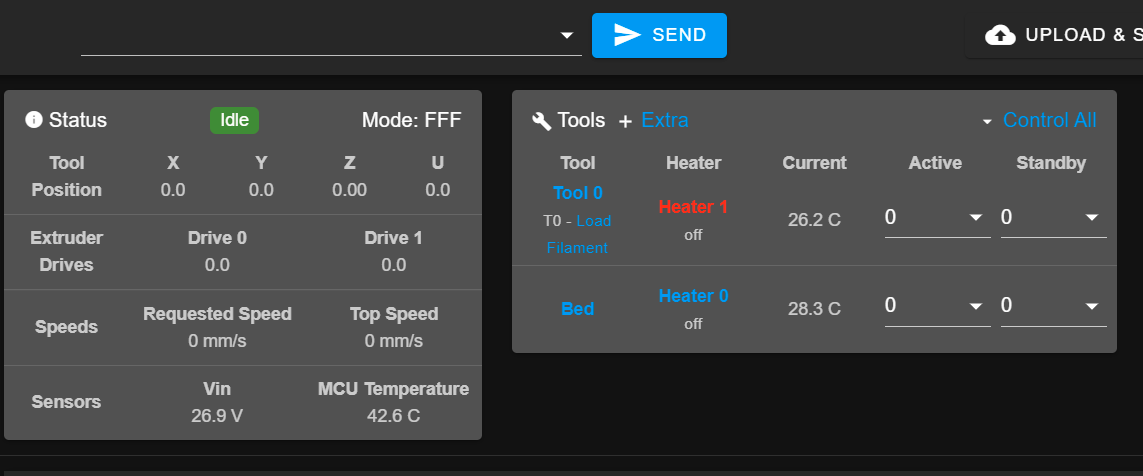

have an IDEX printer.

Duet 2 Wifi + Duex.I've managed to set up the additional axis (U) but I can't seem to set up an additional heater for the second extruder.

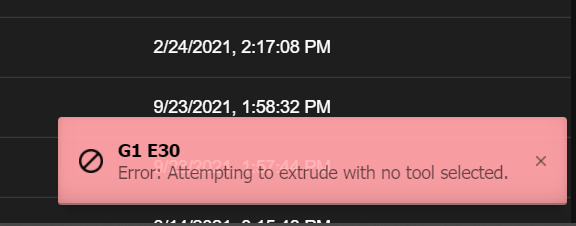

The second drive show on the gui, but when trying to select T2 and sending: G1 E10, I get this error message: Attempting to extrude with no tool selected.

Here is my config.g file:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Feb 24 2021 16:17:10 GMT+0200 (Eastern European Standard Time); Network configurations

M552 S0;

M552 S1;

M587 S"shafir_secure" P"PaSS$shafir123";

;M587 S"Printer_1" P"canada1234567";; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; X0 - right extruder - physical drive 0 goes forwards

M569 P1 S1 ; Y physical drive 1 goes forwards

M569 P2 S1 ; Z physical drive 2 goes forwards

M569 P3 S1 ; E0 - right extruder physical drive 3 goes forwards

M569 P4 S1 ; X1 - left extruder - physical drive 3 goes forwards

M569 P5 S1 ; E1 - left extruder - physical drive 3 goes forwardsM584 X0 Y1 Z2 U3 E4:5 ; set drive mapping

M350 X16 Y16 Z16 U16 E16:16 ; configure microstepping with interpolation

M92 X71.11 Y71.11 Z800 U71.11 E400:400 ; set steps per mm

M566 X720.00 Y720.00 Z240.00 U720.00 E1080.00:1080.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 U9000.00 Z2300.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X2000.00 Y2000.00 U2000.00 Y2000.00 Z600.00 E1600.00:1600.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 U800 E500:500 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y-100 Z-20 S1 ; set axis minima

M208 X350 Y200 Z250 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120CM308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280CM308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e0temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e0heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue; Heaters & bed Tuning

; M307 H0 D200 ;

;M307 H1 R4.063 C68.5 D3.79 S0.2 V26.7 ; E0 PID tunining

M307 H1 R3 C4 D2 S0.25 V15;M307 H0 R0.280 C426.0 D24.18 S1.00 V26.8 B0 ;

M302 S120 R110 ; Allow extrusion starting from 120°C and retractions already from 110°C

-

@eranglr said in Display and control dual extruder issue:

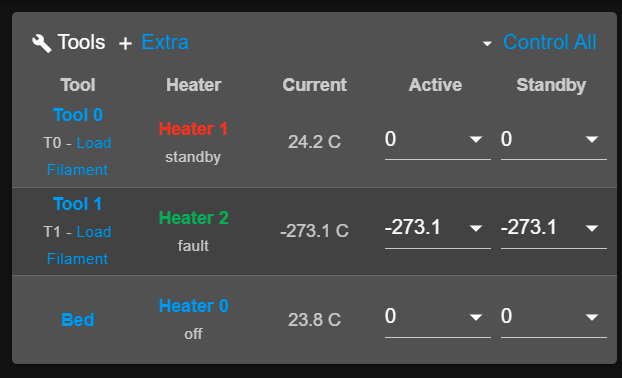

; Tools M563 P0 D0 H1 F0 ; define tool 0Try adding

M563 P1 D1 H2 F1you do not have a tool definition for the second tool

Also your M569/M584 command does not make sense to me if you read the comments

M569 P0 S0 ; X0 - right extruder - physical drive 0 goes forwards M569 P1 S1 ; Y physical drive 1 goes forwards M569 P2 S1 ; Z physical drive 2 goes forwards M569 P3 S1 ; E0 - right extruder physical drive 3 goes forwards M569 P4 S1 ; X1 - left extruder - physical drive 3 goes forwards M569 P5 S1 ; E1 - left extruder - physical drive 3 goes forwards M584 X0 Y1 Z2 U3 E4:5 ; set drive mappingyou have U mapped to the third drive, which you describe as E0, but that could just be an issue with the comments in M569

-

Thanks for the fast reply, it did the trick!!

(I haven't yet connected the thermistor).