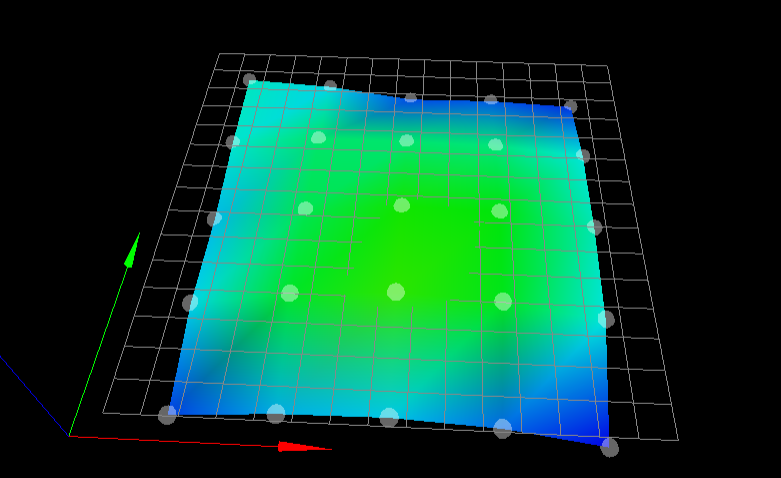

Height Map - Substantial z-offset after setting z-offset

-

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

This is my updated mesh.g

; ###################################################### ;mesh g - manually configured ; ###################################################### M98 P"configs/probe_config.g" ; configure Z probe M98 P"configs/zhome_config.g" ; configure z=0 datum (this still confuses me on how this is set) ; ###################################################### ; Probe bed and create Heightmap ; ###################################################### M561 ; clear any bed transform G28 Z M557 X90:400 Y15:360 P2 ; define probe area and points G29 S0 ; probe and save height mapThat looks to be correct.

I'm working on a response to discuss G30 S-1 and G31.

Frederick

-

@infidelprops

In my brain, when I set my z-offset using the

G30-S1to look trigger height variance and then setting that it in myG31ofprobe_config.g, I thought that was setting my z=0 datum - I am probably wrong.The problem with using G30 S-1 to report the trigger height is it presumes that the logical Z position (what the firmware "thinks" the Z position is) matches the physical Z position.

Consider this:

You jog Z till the tip of the nozzle is exactly 5mm off the surface of the bed which you determined by measuring it with a ruler/scale/thickness gauge.

At that point we know the physical Z position is 5.

If the logical position matches the physical position the DWC will display 5.

If the DWC displays some other number the logical position position is "out-of-sync" with the physical position and it needs to be corrected.

Now assume the probe triggers when the tip of the nozzle is exactly 2mm off the surface of the bed.

We haven't moved the nozzle so it is still 5mm off the bed.

Now we execute G92 Z10 telling the firmware the current position of the nozzle is 10mm off the bed - which it is not - we are lying to the firmware - and it is going to hold that against us.

Now do a single G30 S-1. The nozzle begins to drop and after 3mm of movement it is 2mm off the bed and that is the point at which the probe triggers.

The probing stops and reports the Z position is not 2mm but 7mm because the firmware believed us (even though we lied) and it thinks it started probing from 10mm.

Does that much make sense. I have more to add.

Frederick

-

@fcwilt Yeah that all makes sense, but where I get stuck is if using

G30 S-1to get my trigger height is inaccurate, what's the best method to set myG31Probe Z-offset? -

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

@fcwilt Yeah that all makes sense, but where I get stuck is if using

G30 S-1to get my trigger height is inaccurate, what's the best method to set myG31Probe Z-offset?The problem with the "G30 S-1' approach is you are trying to calibrate the probe using the probe to do the calibration.

That clearly won't work.

Any calibration has to be done against some other accurate standard, something independent of the probe we are trying to calibrate.

I use a 1mm thickness gauge as opposed to something thin like a piece of paper.

You can likely start with a G31 Z Trigger Height setting of 0 which for most probes is going to be too small.

You begin by moving the probe to the center of the bed.

Then you do G1 Z10 followed by a G30. If the probe fails to trigger just use a smaller value as the starting Z position, say G1 Z5.

After the probing is complete you carefully jog down until the tip of the nozzle is just touching the thickness gauge and you now know the physical Z position is 1mm.

You check the DWC to see what it reports, which is the logical Z position.

If it doesn't report 1 then the G31 Z Trigger Height setting needs to be adjusted and the process repeated until you find the setting that does display 1.

Larger Z Trigger Height values will reduce the displayed value.

Frederick

-

@fcwilt Thanks!

So I've got a 1.5mm wrench here and used that, ran the above steps and had it reporting correctly on DWC which had my offset a 0.890

I set that in my G31 in my probe, re-ran a MBL (

G32) and it's 0.00 adjustment neeeded all around

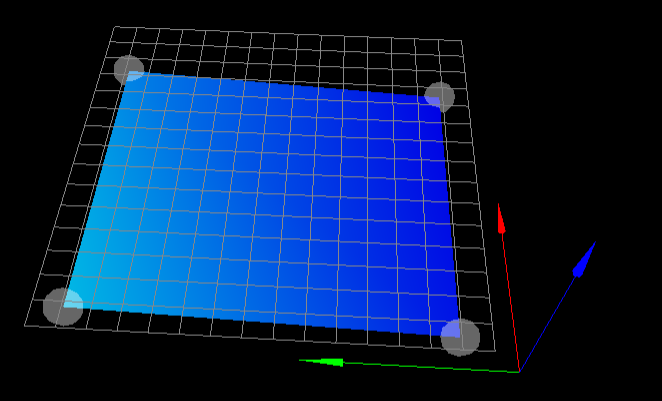

Ran a 4 pt probe test, and still the same problem...

I feel like I'm doing everything right, don't know why this is reporting so badly.

-

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

So I've got a 1.5mm wrench here and used that, ran the above steps and had it reporting correctly on DWC which had my offset a 0.890

What do you mean by "had my offset a 0.890"?

Another approach is to pick a starting value for the Z Trigger height.

Do your G30 probe at bed center.

Do a G90 G1 Znn using the thickness of your "gauge" for nnn and see if the gap between nozzle and bed is "just right".

Frederick

-

@fcwilt said in Height Map - Substantial z-offset after setting z-offset:

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

So I've got a 1.5mm wrench here and used that, ran the above steps and had it reporting correctly on DWC which had my offset a 0.890

What do you mean by "had my offset a 0.890"?

When I reset my

G31Z offset to 0, I reset the machine and then homed all axes, then homed z.

DWC was reporting my Z at 3

I put the 1.5mm wrench under the nozzle and adjusted the tip down 1.5mm and it wasn't touching the wrench yet.

I lowered it another 0.89mm to get it touching the wrench and set that in myG31for my Z offset.

Reset the machine again and then homed all, homed z, put the wrench under the nozzle and lowered it to 1.5mm and it was touching the wrench. -

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

I lowered it another 0.89mm to get it touching the wrench and set that in my

G31for my Z offset.Got you.

The Duet docs use the term "Z Trigger Height" thus my lack of understanding of the term "offset".

But it sounds like you have found the correct value for use in G31.

Using a 4 point test can give misleading results.

Are you using the center of the bed for your XY reference point when doing your G30?

Frederick

-

@fcwilt said in Height Map - Substantial z-offset after setting z-offset:

Are you using the center of the bed for your XY reference point when doing your G30?

Frederick

In my zhome_config.g file, I am just using G30 after I centre the bed, so I believe that I am and when I kick off a G29, it does start at the centre fist.

-

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

@fcwilt said in Height Map - Substantial z-offset after setting z-offset:

Are you using the center of the bed for your XY reference point when doing your G30?

Frederick

In my zhome_config.g file, I am just using G30 after I centre the bed, so I believe that I am and when I kick off a G29, it does start at the centre fist.

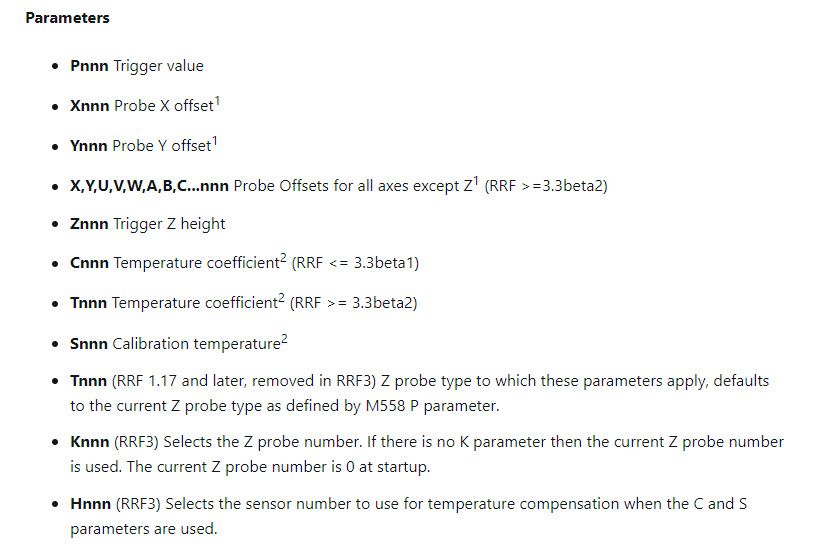

OK here is how a 4 point grid can be misleading.

Imaging the bed rises or falls from the center to the edges in both X and Y.

When you set the Z=0 Datum in the center of the bed but don't probe near the center of the bed but just the near the edges you can get a picture like yours because all of the probed points are above/below the Z=0 Datum.

Try a 9 point grid which will include a probed point near the center of the bed and I think you will see what I mean.

Frederick

-

@fcwilt Yeah, I was stating to think my probe points are probably too far in the corners which is why I get the big low hanging gaps.

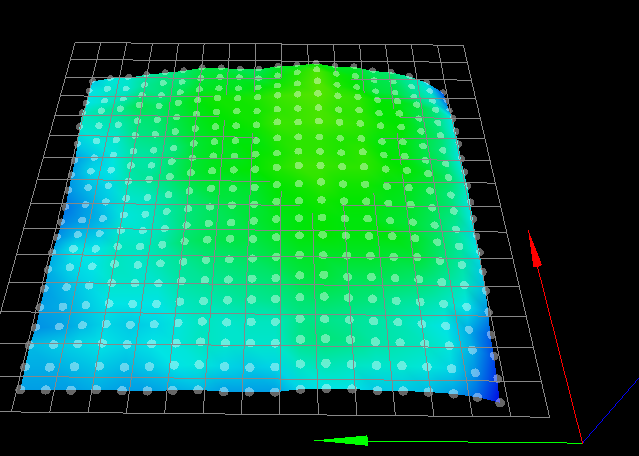

I upped the points to 3 and started to a similar result:

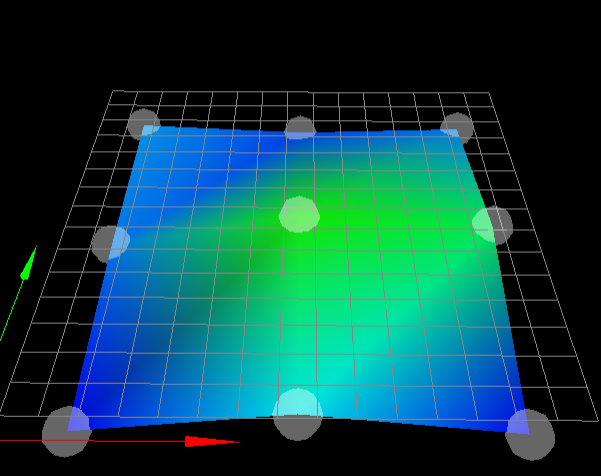

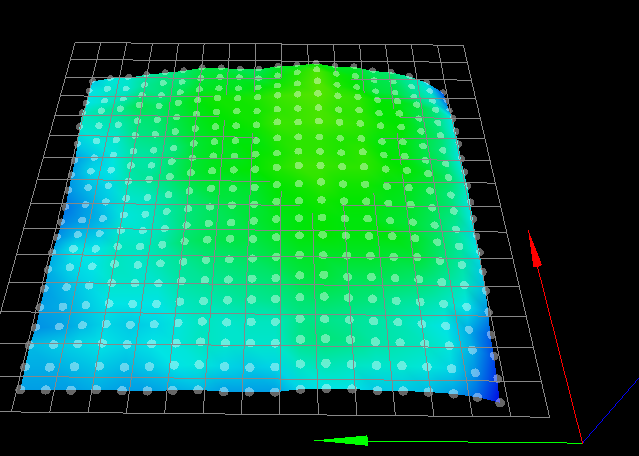

And then went to 5 points and started seeing the old mesh I used to have, which is slanted on one side:

I read another post from a frustated BLT user who said he needed to manually move one of his z-rods to get it set right and I've just dont that and am seeing the slant start to get better...

But I also think that I may want to control my two z motors seperately to get better levelling as right now they only seen as one motor in the config and that may help my slant become more even.

-

So just read up and I can't do MBL on my 4 bed screws AND my 2 Z rod screws, so I won't be able to help adjust the slant I've been seeing

-

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

So just read up and I can't do MBL on my 4 bed screws AND my 2 Z rod screws, so I won't be able to help adjust the slant I've been seeing

If you configure things so ABL can be used with your two steppers you can cannot use the MBL assistant.

But you can use G29 to help you adjust the 4 bed screws - thought it takes a bit of practice.

What you do is create 4 point height maps and based on what you see when you view the height map (or read out from the points of the height map) you adjust 3 of the 4 screws, more of less by trial-and-error, until you are happy with the results.

I've done this in the past and it works pretty well.

Frederick

-

@infidelprops

Though your bed looks pretty level already.

I put off trying out ABL because it meant a good deal of work modifying my printer but I finally did it.

It's really nice to let the firmware do the work.

Did I post the link to my quick-and-dirty video of it working?

Frederick

-

@fcwilt Yeah - I've got G32 mapped to my bed screws and I adjust accordingly... and then I run a G29 to get the mesh once I level the 4 points...

I've seen that sometimes this can have the opposite effect and I end up running a smaller G29 probe point, adjust the screws and once happy, run the 20 point probe.

Mesh has gotten much better throughout the day, huge thank you for all the help mate.

Of topic question... if I wanted to purchase a new bed plate which is more level, where would I go about looking for one?

-

@fcwilt said in Height Map - Substantial z-offset after setting z-offset:

@infidelprops

Though your bed looks pretty level already.

I put off trying out ABL because it meant a good deal of work modifying my printer but I finally did it.

It's really nice to let the firmware do the work.

Did I post the link to my quick-and-dirty video of it working?

Frederick

No, and would love to watch it!

-

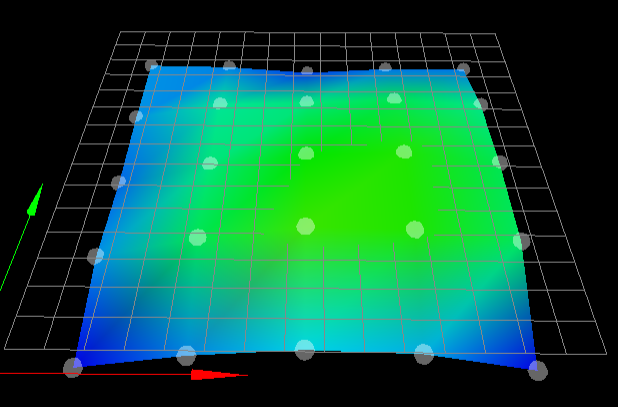

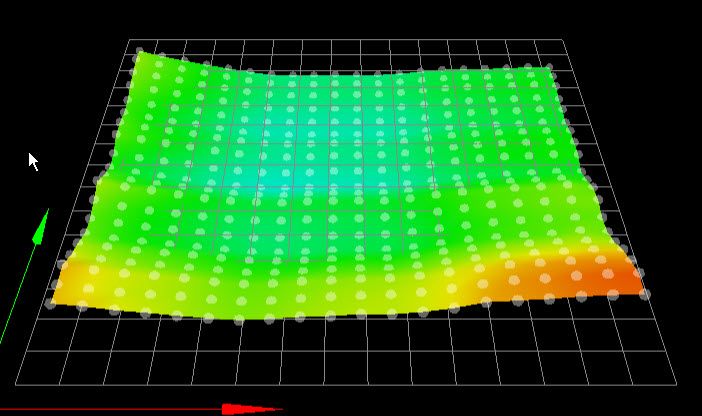

And this is my mesh now... I'd still like to get it better, but don't know what else to do

-

@infidelprops said in [Height Map - Substantial z-offset after setting z-offset]>

No, and would love to watch it!

You will notice that when making this conversion I decided to also try using belts instead of lead screws for the Z axis.

I like it so much any future printers are going to use belts.

Here is the video:

-

@fcwilt Thanks, I'll watch it shortly!

I just tried a bed level print and some really weird behaviour....

On the 3/4 of the bed, the files skirt starts to print, but on the back left and left side, it doesn't print at all.. and comparing it to my mesh, those sides are low, not high, which would be causing it to not extrude since it's to close to the print bed.

-

@infidelprops said in Height Map - Substantial z-offset after setting z-offset:

And this is my mesh now... I'd still like to get it better, but don't know what else to do

That's really pretty good.

I would guess that it might just be an accurate reflection of your bed.

Cast aluminum tool plate is the material of choice but even that can require the skills of a machinist.

One site for tool plate lists the material as being flat within 0.015" but that works out to appx 0.4 mm - which isn't that great - given print heights of 0.1 and up.

I've fitted 3 of my 4 printers with tool plate. Two of the pieces were better than spec and I'm quite pleased.

The last one is within spec but not what I hoped for.

There are some places that will mill/grind a plate flatter than 0.4mm.

Here is one that has reached out to me in the past.