Solved [3.4.0b6] T0 P0 causes state to show as "changing tool"

-

Just updated to 3.4.0b6 and noticed that after rebooting, the printer shows a status of "changing tool"

In config.g I had;Select tool zero T0 P0 ; select tool zero but don't run any tool change macros M568 R0 S0 P0 A0 ; set heater on T0 to offBoth tpre0.g and tpost0.g exist, but contain nothing.

tpost0.g did contain M116 P0 , but commenting that out made no difference.Removing T0 from config.g returned printer to normal status showing idle at startup.

EDIT:

I think I just figured this out.

If I put the T0 P0 at the very end of config.g, then it works as expected.

My original file had it placed before some conditional code that used state.currentToolFor some reason that causes this "issue"

However if I run M98 P"0:/sys/config.g" nothing untoward is shown in the console.CORECTION: Moving the T0 to the end does show an index out of bounds message when the conditional code is run (which is to be expected)

The behavior didn't show in b5

-

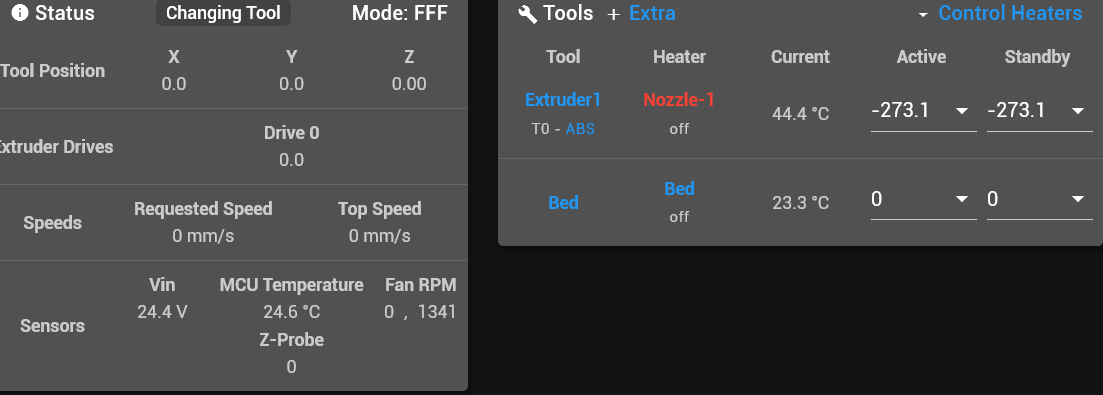

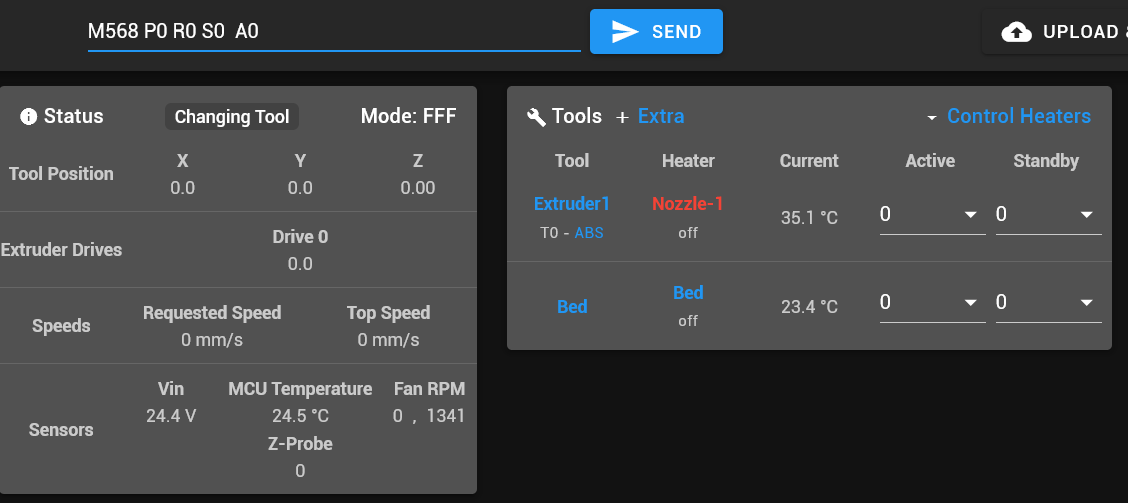

I've also noticed that my original command to set the tool temps and status result in the temps showing as -273.1

In config.g as the very last statement I haveM568 P0 R0 S0 A0The status shows this

If I then run the same command from teh console, the active & standby temps are set to zero as expected.

-

@owend With the various edits it is a bit confusing what you have in your config.g, might be worth posting the version that gives the -273 error?

-

@gloomyandy

After a bit more playing around I have found.The -273 is still present of I roll back to 3.4b5

The "changing tool" issue is not there in b5

This is my complete config.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.4 on Sat Jan 04 2020 09:46:45 GMT+1000 (Australian Eastern Standard Time) M81 C"pson" ; define the pson pin as power control and set to off by default ;Select tool zero T0 P0 ; select tool zero but don't run any tool change macros ; Global variable to run/not run daemon.g - checked in daemon.g and abort if false if !exists(global.RunDaemon) global RunDaemon = true else set global.RunDaemon = true ; Global variable to run/not run heater checks daemon.g - checked in daemon.g and abort if false if !exists(global.RunHeaterChecks) global RunHeaterChecks = true else set global.RunHeaterChecks = true if !exists(global.Cancelled) ; global variable for exiting out of loops global Cancelled = false else set global.Cancelled = false if !exists(global.filamentDistance) global filamentDistance = 0 ; global for use to allow filament to feed for set distance after sensor trips else set global.filamentDistance = 0 ; serial comms / Paneldue M575 P1 B57600 S1 ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"3Dprinter" ; set printer name ; Network M554 P192.168.1.1 ; set gateway M553 P255.255.255.0 ; set netmask M552 S1 P"DARE" ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S1 ; physical drive 0 (X) goes forwards M569 P1 S0 ; physical drive 1 (Y) goes backwards M569 P2 S1 ; physical drive 2 (Z) goes forwards M569 P3 S0 ; physical drive 3 (E0) goes backwards M584 X0 Y1 Z2:4 E3 ; two Z motors connected to driver outputs Z and E1 M671 X-74:240 Y79:79 S5.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation for XYZ M350 E16 I1 ; Configure microstepping with interpolation for E0 M92 X100.00 Y100.00 Z400.00 ; set steps per mm XYZ M92 E854 ; set E steps/mm for Titan Aero ; axis settings M98 P"0:/sys/set_max_speeds.g" ; set all the max speeds in macro as these are adjusted during home moves so we only want to adjust in one spot M906 X1100 Y1100 Z1100 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S600 ; Set idle timeout at 10 minute ; Axis Limits M208 X0:215 Y-2:200 Z0:180 ; X carriage moves from 0 to 200, Y bed goes from -2 to 200 ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H6 F600:120 T4800 A10 S0.03 R0.5 B0 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X26.2 Y-1 Z0.48 ; set Z probe trigger value, offset and trigger height M557 X30:200 Y10:180 S30 ; define mesh grid ;Calculate bed centre if !exists(global.Bed_Center_X) global Bed_Center_X = floor(move.axes[0].max / 2) if !exists(global.Bed_Center_Y) global Bed_Center_Y = floor(move.axes[1].max / 2) ; Heaters M308 S0 P"bedtemp" Y"thermistor" A"Bed" B3950 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 Q10 ; create bed heater output on bedheat and map it to sensor 0 and set PWM frequency to 10hz M140 H0 ; Set bed themp to zero M143 H0 S130 A0 C0 ; set temperature limit for heater 0 to 130C - fault if too high M308 S1 P"e0temp" A"Nozzle-1" Y"thermistor" T100000 B3950 C0 ; configure sensor 1 as thermistor on pin e0temp - Aurarum cartrdge thermistor M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S300 A0 C0 ; set temperature limit for heater 1 to 300C - fault if too high ;echo "sensor create time: " ^ state.upTime ^ "." ^ state.msUpTime ; Set PID autotune parameters M307 H0 R0.553 C379.7 D21.16 S0.80 B0 V0 M307 H1 B0 R1.594 C358.1:217.5 D6.05 S1.00 V24.3 ;set PID values for heater 1 (hotend) ; Joystick M308 S3 P"exp.thermistor4" Y"linear-analog" A"JoyStick-X" F1 B100 C-100 ; set analog input on E3 Temp with min/max of -100 to 100 M308 S4 P"exp.thermistor6" Y"linear-analog" A"JoyStick-Y" F1 B100 C-100 ; set analog input on E5 Temp with min/max of -100 to 100 M581 T7 P7 ; set up trigger for GpIn 7 M950 J7 C"!^exp.31" ; Input 7 uses Expansion 31 pin activate pullup and inverted ; Servos and input/output M950 P5 C"exp.e5_stop" ; Output 5 uses E5_STOP pin M950 J6 C"exp.e6_stop" ; Input 6 uses E6_STOP pin ; Filament monitor M591 P1 C"e0stop" S1 D0 ; filament monitor for extruder 0 connected to E0 endstop ; Fans M950 F0 C"fan0" Q50 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"Part_Fan" S0 B2.0 H-1 ; set fan 0 name and value. Thermostatic control is turned off ; Adjust MCU temp reading to match ambient ;water pump M950 F1 C"!fan1+^exp.pb6" Q25000 ; create fan 1 (water pump) on inverted pin fan1 and set its frequency. Set RPM to E3 stop with pullup enabled M106 P1 C"Water Pump" H1 L0.5 X1 B1.2 T50:60 ; set fan 1 name and value. Thermostatic control is turned on. Monitoring hoted sensor ; water temp monitor & fan M950 F2 C"!fan2+^exp.e3_stop" Q25000 ; create fan 2 on pin fan2 and set its frequency M308 S5 P"e1temp" Y"thermistor" A"Water temp" T10000 B3950 ; Configure Water temp sensor M106 P2 C"Radiator Fan" H5 L0 X1 B1.2 T33:38 ; set fan 4 value, turn on at 30% if the water temperature reaches 30C, and increase to full speed gradually as the temperature rises to 40C ; MCU temp sensor M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor ; Calibrate MCU temp M912 P0 S-4 ; Tools M563 P0 S"Extruder1" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ; Global Variables for heater checking routine in daemon.g if !exists(global.HeaterCheckInterval) global HeaterCheckInterval=6 ; variable for use in daemon.g sets interval of heater checks else set global.HeaterCheckInterval=6 ; variable for use in daemon.g sets interval of heater checks while heat.heaters[1].current=2000 ; loop until thermistor values are stable G4 P1 if iterations > 10000 ; if it takes more than 10 seconds we have a problem with the thermistor M118 P0 L1 S"Thermistor failed to stabilize in less than 10 seconds" break ;echo "sensor stable time: " ^ state.upTime ^ "." ^ state.msUpTime if !exists(global.LastTemp) || global.LastTemp=null global LastTemp=heat.heaters[1].current ; Set variable to current extruder temp. else set global.LastTemp=heat.heaters[1].current ; Set variable to current extruder temp. G4 P10 if !exists(global.LastCheckTime) global LastCheckTime=0 ; variable for use in daemon.g else set global.LastCheckTime=0 ; variable for use in daemon.g if !exists(global.BedPreheatTemp) global BedPreheatTemp=0 ; variable for use in preheating else set global.BedPreheatTemp=0 ; variable for use in preheating ; extrusion if !exists(global.LoadedFilament) || global.LoadedFilament=null; global variable to hold filament name global LoadedFilament="No_Filament" ; create a filament variable G4 P10 if move.extruders[state.currentTool].filament="" echo "No filament loaded. Cold extrude & retract set to defaults" M302 S190 R110 ; Allow extrusion starting from 190°C and retractions already from 110°C (defaults) set global.LoadedFilament="No_Filament" else set global.LoadedFilament=move.extruders[state.currentTool].filament ; set the variable to the currently loaded filament echo "Loading config for " ^ global.LoadedFilament ^ " filament" M703 ; if a filament is loaded, set all the heats and speeds for it by loading config.g G4 P10 ; Custom settings M376 H4 ; set bed compensation taper (H4 means taper over 4mm) ; Power failure recovery M911 S22.5 R23.0 P"M42 P5 S0 M106 P0 S0 M913 X0 Y0 G91 M83 G1 Z3 E-2 F1000" ; If power drops below 22v then turn off fans, Set X & Y current to zero, raise head, retract. ; turn on LED strip driven by P5 output M42 P5 S1 ;Valve Control test to control servo position via fan speed ; Set up scaling variables {(output_end - output_start) / (input_end - input_start)} ;M950 S1 C"exp.heater4" ; assign GPIO port 0 to heater4 on expansion connector, servo mode if !exists(global.InputStart) || global.InputStart=null global InputStart=0 else set global.InputStart=0 G4 P10 if !exists(global.InputEnd) || global.InputEnd=null global InputEnd=1 else set global.InputEnd=1 G4 P10 if !exists(global.OutputStart) || global.OutputStart=null global OutputStart=0 else set global.OutputStart=0 G4 P10 if !exists(global.OutputEnd) || global.OutputEnd=null global OutputEnd=180 else set global.OutputEnd=180 G4 P10 if !exists(global.ScaleFactor) || global.ScaleFactor=null global ScaleFactor=(global.OutputEnd - global.OutputStart) / (global.InputEnd - global.InputStart) ; no need for the math in this instance but it makes it clear how you arrive at the value. else set global.ScaleFactor=(global.OutputEnd - global.OutputStart) / (global.InputEnd - global.InputStart) G4 P10 if !exists(global.ServoOut) || global.ServoOut=null global ServoOut=floor(global.ScaleFactor * (fans[0].actualValue - global.InputStart) + 0.5) + global.OutputStart ; calculate position required on sevo - use floor to apply rounding else set global.ServoOut=floor(global.ScaleFactor * (fans[0].actualValue - global.InputStart) + 0.5) + global.OutputStart ;M280 P1 S{global.servo_out} ; adjust valve position to reflect fan speed. ;play startup tune G4 S8 ; Allow time for PanelDue to start & wifi connection etc M98 P"0:/macros/songs/itchyscratchy.g" ; Play tune M501 ; load config-overide.g ; configure accelerometer M955 P0 I06 R10 S2000 Q2000000 C"spi.cs3+spi.cs4" ; configure accelerometer ; Set temps on heater 0 M568 P0 R0 S0 A0 ; set heater on T0 to off -

Just noticed that T0 P0 is still right at the start.

That's not how I had it.

I moved it there while trying to work out what was going on.

It's normally just after where I defined the tool -

@owend thanks for your report. I can see why the status shows as "Changing tool" after the tool change has finished, and I will fix that in the next build. A workaround for now would be to omit the P0 parameter, if it is safe to run your tpre0.g and tpost0.g files before the machine has been homed.

-

undefined OwenD has marked this topic as solved

undefined OwenD has marked this topic as solved

-

@dc42

No problem

I can safely omit the P0

I'll mark as solved pending the next build.