M671 definition with gobal variable problem

-

here i have my config, for a machine that could be model XL os ST (bed size change) and have a IR probe or a superpinda.

I have problems with the M671 comand that does not accept a global variable with the text.

config.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ============================================================== ; ; Hbot XL by Campy3d ; global model = 1 ; 1 = XL 2 = ST for CUSTOM (edit in config-var.g on you model type XT or ST) global probetype = 2 ; 1 = IR mini 2 = Superpinda ; =============================================================== ; Load model type M98 P"0:/sys/config-var.g" S{global.model} L0 Z0 ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"HBot XL RRF3" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S0 ; enable Telnet ; Drives M569 P0 S1 ; X physical drive 0 goes forwards M569 P1 S0 ; Y physical drive 1 goes backwards M569 P2 S1 ; Z1 physical drive 2 goes forwards M569 P3 S0 ; E0 physical drive 3 goes backwards M569 P4 S1 ; Z2 physical drive 3 goes backwards M584 X0 Y1 Z2:4 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E400.00 ; set steps per mm M566 X500.00 Y500.00 Z60.00 E600.00 ; set maximum instantaneous speed changes (mm/min) M566 P1 M203 X18000.00 Y18000.00 Z800.00 E4800.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z400.00 E4000.00 ; set accelerations (mm/s^2) M204 P1200.0 T5000.0 ; set print and travel accelerations (mm(s^2) M566 E400 ;300 ; Set maximum instantaneous speed changes (JERKS) (mm/min) ONLY EXTRUDER M205 X8 Y8 Z8 ; Set maximum instantaneous speed changes (JERKS) (mm/seg) XYZ . USE this for Marlin COMPATIBILITY M906 X1000 Y1000 Z1000 E560 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z-1 S1 ; set axis minima M208 X{global.sizeX} Y{global.sizeY} Z400 S0 ; set axis maxima ; Definimos Leadscrews para el Z_Tilt M671 {global.lscrews} ;M98 P"0:/sys/config-var.g" S0 L{global.model} Z0 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis --- S Ajustarlo segun sensibilidad del probe ; Endstops M574 X1 S1 P"!xstop" ; configure active-low endstop for low end on X via pin xstop M574 Y2 S1 P"!ystop" ; configure active-low endstop for high end on Y via pin ystop ; Filament Sensor M98 P"0:/sys/00-Functions/FilamentsensorStatus" ; Z-Probe M98 P"0:/sys/config-var.g" S0 L0 Z{global.probetype} ; ; Heaters BED M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 A"Heated Bed" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M143 H0 P0 S120 A2 ; disable temporarily H0 if temp exceeds 120C M143 H0 P0 S130 A0 ; heater fault H0 if temp exceeds 130C M570 H0 P60 T15 S0 ; Heaters HOTEND M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 A"Nozzle T0" ; Configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S290 ; set temperature limit for heater 1 to 300C M143 H1 S275 A2 ; disable temporarily H1 if temp exceeds 275C M143 H1 S285 A0 ; heater fault H1 if temp exceeds 280C M570 H1 P10 T30 S0 ; heater fault for 10 seg of 30ยบC excursion ;PID backup M307 H0 R0.322 C632.982:632.982 D5.13 S1.00 V24.3 B0 I0 ; Bed PID M307 H1 R2.813 C295.614:204.933 D6.24 S1.00 V24.5 B0 I0 ; Hotend PID ; Fan0 = Part Coooling M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"LayerFAN" S0 H-1 B0.3 ; set fan 0 name and value. Thermostatic control is turned off ; Fan1 = Hotend M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"ToolFAN" S1 H1 T60 ; set fan 1 name and value. Thermostatic control is turned on ; Fan2 = Chamber cam M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 I0 C"ChamFAN" S0 H-1 ; Set fan 2 PWR fan ; Sensor = MotherBoard Cooling ;----MCU & DRIVERS sensors------ ;M912 P0 S-13 ; Cpu temp correction MUST BE ADJUSTED ON EACH BOARD M308 S3 Y"mcu-temp" A"MCU" ; create sensor for MCU temp M308 S3 Y"mcutemp" M308 S4 Y"drivers" A"Drivers" ; create sensor for drivers temp M308 S4 Y"drivers" ; Tools M200 D1.75 M563 P0 S"T0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M302 S180 R180 ; allow extrusion starting from 180°C and retractions already from 180°C ; Firmware Retraction M404 N1.75 ; Define filament diameter for print monitor M207 S0.95 R0 F2400 Z0 ; Firmware retraction ; Bed Compensation Taper M376 H10 ; Bed Compensation Taper 10mm ; Pressure Advance ;M572 D0 S0.09 ;PLA ;M572 D0 S0.11 ;PETG ;M572 D0 S0.1 ;ABS ; LCD M575 P1 S1 B57600 ; enable support for PanelDue ; LEDS M950 P1 C"e1heat" Q500 ;use heater 1 outupt for LED M42 P1 S0 ; turn off LEDS ; Power Management M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; Selecto Tool 0 T0 ; select first tool ; Load config-override M501 ; load saved parameters from non-volatile memory ; Load Preloaded filamento config M703config-var.g

; Model type XL or ST if {param.S}==1 || {param.S}==2 if {param.S}==1 ; XL global sizeX = 330 global sizeY = 325 global posZ1 = -59.13 global posZ2 = 437.87 global posY = 164 elif {param.S}==2 ; ST global sizeX = 310 global sizeY = 208 global posZ1 = -55.50 global posZ2 = 411.50 global posY = 144 ; end if bedsize ; ================================================================================ ; Varibales definition if global.probetype == 1 ; Z-Probe IR mini global offsetPX = 18 global offsetPY = -38 global tiltZ1=18 if {param.S}=1 global tiltZ2=304 elif {param.S}=2 global tiltZ2=292 ; end if global meshmaxY= {global.sizeY-abs(global.offsetPY)} elif global.probetype == 2 ; Z-Probe Superpinda global offsetPX = -25 global offsetPY = 0 global tiltZ1=30 if {param.S}=1 global tiltZ2=295 elif {param.S}=2 global tiltZ2=272 ; end if global meshmaxY= {global.sizeY-(abs(global.offsetPY)+10)} ; end if variable definition ; Mid Points and Ztilt Points global midX={(global.sizeX/2)-global.offsetPX} global midY={(global.sizeY/2)-global.offsetPY} global midXP={global.sizeX/2} global midYP={global.sizeY/2} global meshmaxX= global.tiltZ2 ; M671 definition global lscrews=("X"^{global.posZ1}^":"^{global.posZ2}^" Y"^{global.posY}^":"^{global.posY}^" S5") ; end if ;================================================================================================== ; Locate LeadScrews if {param.L}==1 || {param.L}==2 if {param.L}==1 ; XL M671 X-59.13:437.87 Y164:164 S5 elif {param.L}==2 ; ST M671 X-55.50:411.50 Y164:164 S5 ; end if bedsize ;================================================================================================== ; Probe Setup if{param.Z}==1 || {param.Z}==2 ; Probe type IR mini if global.probetype == 1 ; Z-Probe IR mini M558 P1 C"zprobe.in" H5 F360:120 T9000 R0.4 A3 S0.03 ;B1 ; Set Z probe type mini ir sensor G31 P500 X{global.offsetPX} Y{global.offsetPY} Z2.175 ; set Z probe trigger value, offset and trigger height elif global.probetype == 2 ; Z-Probe Superpinda M558 P8 C"zprobe.in" H5 F360:120 T9000 R0.4 A3 S0.03 ;B1 ; Set Z probe type mini ir sensor G31 P1000 X{global.offsetPX} Y{global.offsetPY} Z0.74 ; set Z probe trigger value, offset and trigger height ;Inductivo ; end if M557 X20:{global.meshmaxX} Y20:{global.meshmaxY} P3 ; define mesh grid P6 hace 6 malla de 6x6 ; end if

I am NOT a programer, just a random guy trying to this...so any help would be apreciated

-

Hi, I don't think you can't write parameters in the way you have done.

Try this instead:

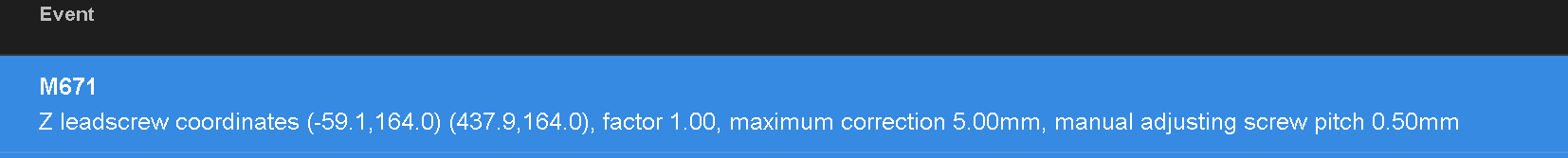

M671 X{global.posZ1,global.posZ2} Y{global.posY,global.posY} S5 -

@gixxerfast said in M671 definition with gobal variable problem:

M671 X{global.posZ1,global.posZ2} Y{global.posY,global.posY} S5

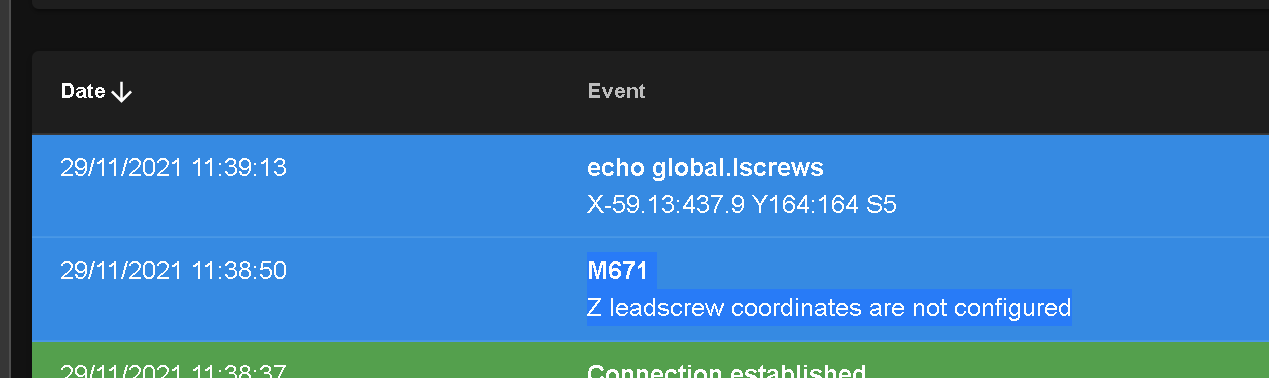

Worked, sort off..

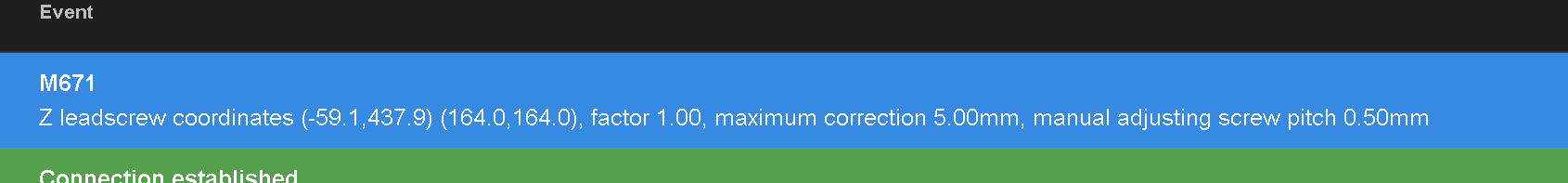

instead of X1:X2 Y1:Y2 it has to be parsed as Leadscrew1 (X1,Y1) and Leadscrew2 (X2,Y2)

M671 X{global.posZ1,global.posY} Y{global.posZ2,global.posY} S5

So X and Y could lean to error if parsed as variable

-

undefined Phaedrux moved this topic from Tuning and tweaking

undefined Phaedrux moved this topic from Tuning and tweaking