Extrusion Control in DWC unavailable, even after M302 P1

-

Trying to figure out why I can't run my extruder. M122 shows some weird messages:

Driver 0: position 38683, standstill, read errors 0, write errors 1, ifcnt 23, reads 6775, writes 6, timeouts 0, DMA errors 0 Driver 1: position 38683, standstill, read errors 0, write errors 1, ifcnt 23, reads 6775, writes 6, timeouts 0, DMA errors 0 Driver 2: position 38683, standstill, read errors 0, write errors 1, ifcnt 23, reads 6775, writes 6, timeouts 0, DMA errors 0 Driver 3: position 0, standstill, read errors 0, write errors 1, ifcnt 20, reads 6775, writes 6, timeouts 0, DMA errors 0 Driver 4: position 0, standstill, read errors 0, write errors 1, ifcnt 20, reads 6775, writes 6, timeouts 0, DMA errors 0 Driver 5: position 0, assumed not present Driver 6: position 0, assumed not presentI only have 4 motors in the printer X, Y, Z & E. Why would both 3 & 4 report errors? Did I fry a driver somehow?

Since I know someone will ask for it, here's my config.g:

; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Griffin Delta" ; set printer name M665 R130 L288.87 B130 H229.4 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 C"*" ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E506.92 ; set steps per mm M566 X12000.00 Y12000.00 Z12000.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) ---was 1200 M203 X18000.00 Y18000.00 Z18000.00 E2400.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z5000.00 E1000.00 ; set accelerations (mm/s^2) -- was 1000 M906 X1000 Y1000 Z1000 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop ; Z-Probe M558 P1 X0 Z0 H5 F600 T5000 C"zprobe.in+zprobe.mod" ; Set Z probe type to dc42 IR_PROBE G31 P450 X18 Y18 Z0.934 ; set Z probe trigger value, offset and trigger height M557 R75 S20 ; define mesh grid ; Bed Heater M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 A"Bed Heater" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 ;M307 H0 B0 S0.90 ; use PID tuning for the bed heater and set PWM limit // CONFIG_OVERRIDE handles this M140 H0 ; map bed to heater 0 M140 S-273 R40 ; active/standby to 25/40. turn off bed heater by setting to -273 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Hot End Heater M308 S1 P"e0temp" Y"thermistor" T100000 B4138 A"Hot End" ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 ;M307 H1 B0 S0.90 ; use PID tuning for the heater and set PWM limit // CONFIG_OVERRIDE handles this M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans Q30000 Q1000 M950 F0 C"fan0" ; Layer fan on pin fan0 and set its frequency M106 P0 S0 H-1 C"Print Layer Fan" ; set fan 0 starting speed. Thermostatic control is disabled M950 F1 C"fan1" ; Heat sink fan on pin fan1 and set its frequency M106 P1 S1 H1 T45 C"HotEndFan" ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"DeltaEffector" H1 F0 ; define tool 0 with heater 1, fan 0 ;G10 P0 R25 S125 ; Active 125 Standby 25 M568 P0 R20 S25 A0 ; replaces g10; Set tool 0 Active/Standby=150C/25C and Current State = Off R25 S150 A0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool -

@oracledude said in Extrusion Control in DWC unavailable, even after M302 P1:

M563 P0 S"DeltaEffector" H1 F0 ; define tool 0 with heater 1, fan 0

Your tool definition misses a D parameter for the extruder drive.

-

@o_lampe - It seemed to be hit or miss in examples with the D0 in tool definition, so I left it out at first. Re-added it, but still getting no joy from the extruder section of DWC, nor can I use GCODE to cold extrude.

M122:

=== Diagnostics === RepRapFirmware for Duet 2 Maestro version 3.3 (2021-06-15 21:47:01) running on Duet Maestro 1.0 Board ID: 08DAM-9F9GA-J24TD-6JKD0-3S86R-KP3UT Used output buffers: 5 of 24 (17 max) === RTOS === Static ram: 23556 Dynamic ram: 66972 of which 0 recycled Never used RAM 24968, free system stack 214 words Tasks: NETWORK(ready,26.3%,262) HEAT(delaying,0.1%,353) Move(notifyWait,0.1%,403) TMC(notifyWait,1.3%,117) MAIN(running,71.8%,493) IDLE(ready,0.5%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:00:32 ago, cause: software Last software reset at 2021-12-06 08:17, reason: User, GCodes spinning, available RAM 24968, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 940 MCU temperature: min 22.1, current 23.2, max 23.4 Supply voltage: min 14.0, current 14.1, max 14.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: position 38683, standstill, read errors 0, write errors 1, ifcnt 23, reads 5391, writes 6, timeouts 0, DMA errors 0 Driver 1: position 38683, standstill, read errors 0, write errors 1, ifcnt 23, reads 5391, writes 6, timeouts 0, DMA errors 0 Driver 2: position 38683, standstill, read errors 0, write errors 1, ifcnt 23, reads 5391, writes 6, timeouts 0, DMA errors 0 Driver 3: position 0, standstill, read errors 0, write errors 1, ifcnt 20, reads 5391, writes 6, timeouts 0, DMA errors 0 Driver 4: position 0, standstill, read errors 0, write errors 1, ifcnt 20, reads 5391, writes 6, timeouts 0, DMA errors 0 Driver 5: position 0, assumed not present Driver 6: position 0, assumed not present Date/time: 2021-12-06 08:18:22 Slowest loop: 24.27ms; fastest: 0.16ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 15.0MBytes/sec SD card longest read time 0.5ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 10.83ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplexupdated config.g line:

; Tools M563 P0 S"DeltaEffector" H1 F0 D0 ; define tool 0 with heater 1, fan 0, extruder 0 -

If you send M98 P"config.g" what does it respond with?

What version of DWC are you using?

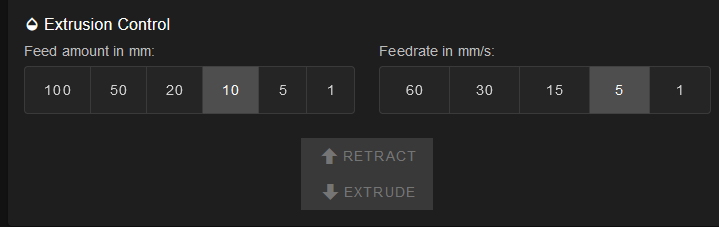

What exactly do you see in DWC?

Can you show a screenshot of what you see and explain what you expect to see? -

M98 P"config.g" HTTP is enabled on port 80 FTP is enabled on port 21 TELNET is enabled on port 23 Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 265C Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 522CDuet Web Control 3.4.0-b6

I'd expect Retract and Extrude to become available. I don't think it's a DWC issue though, since G1 F200 E100 isn't engaging the stepper at all.

The extruder motor works when connected to a different driver (x,y,z)

-

@oracledude do you have a tool active?

-

Doesn't the T0 at the end of the config.g select a tool?

-

@oracledude If you have a heater and extruder mapped to a tool (

M563 ... H1 D0), it must be active (selected) and up to temperature (> 160C for extrusion AFAIR). You can override the temperature limitation by sendingM302 P1. -

Seems that once I clicked on the tool in DWC it worked, even after several resets. Guess that solved it. Thanks all.